INSTALLATION INSTRUCTIONS

R

−

410A Split System Heat Pump

16

428 01 5301 05

Specifications subject to change without notice.

SEQUENCE OF OPERATION

A. COOLING MODE

On a call for cooling, the thermostat makes circuits R

−

O,

R

−

Y, and R

−

G. Circuit R

−

O energizes reversing valve,

switching it to cooling position. Circuit R

−

Y energizes

contactor, starting outdoor fan motor and compressor.

Circuit R

−

G energizes indoor unit blower relay, starting

indoor blower motor.

When thermostat is satisfied, its contacts open,

de

−

energizing contactor and blower relay. Compressor

and motors stop.

NOTE:

If indoor unit is equipped with a time

−

delay relay

circuit, the blower runs an additional length of time to

increase system efficiency. (Applies to both cooling and

heating modes.)

B. HEATING MODE

On a call for heating, the thermostat makes circuits R

−

Y

and R

−

G (circuit R

−

O is NOT made, and the reversing

valve stays in the de

−

energized, heating position). Circuit

R

−

Y energizes contactor, starting outdoor fan motor and

compressor. Circuit R

−

G energizes indoor blower relay,

starting blower motor. If the room temperature continues

to fall, circuit R

−

W2 is made through the second

−

stage

room thermostat bulb. Circuit R

−

W2 energizes a

sequencer, bringing on the first bank supplemental

electric heat and providing electrical potential to the

second heater sequencer (if used). If outdoor

temperature falls below the setting of the outdoor

thermostat (field

−

installed option), contacts close to

complete the circuit and bring on the second bank of

supplemental electric heat.

When the thermostat is satisfied, its contacts open,

de

−

energizing contactor, blower relay, and sequencer.

Compressor, motors, and heaters stop.

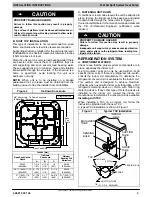

MAINTENANCE

Condensate Drain

During the cooling season, check monthly for free flow of

drainage and clean if necessary.

Cleanliness

These tips will help keep the heat pump looking better and

working more efficiently:

1. Free flow of air is essential. Keep fences, shrubs,

trash cans, and other obstructions at least 18

inches (0.5m) from all coil inlets.

2. Keep the coil free of grass clippings, leaves,

weeds, and other debris.

NOTE:

Coil may occasionally require cleaning with

a liquid solution. The coil must be cold when

cleaning. Use an alkaline based cleaner only.

Cleaning a hot coil or using an acid based cleaner

will remove the paint from the fins and may clog the

coil.

3. Never use a weather cover over the outdoor unit

unless it is a ventilated type or made of breathable

fabric that will allow moisture to evaporate rapidly.

A cover that holds moisture in the unit will cause

more rust build

−

up and damage than normal

exposure to weather.