INSTALLATION INSTRUCTIONS

R

−

410A Split System Heat Pump

428 01 5301 05

3

Specifications subject to change without notice.

!

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Top surface of platform must be above estimated snow-

fall level to prevent snow blocking coil and to allow water

melt to drain from unit.

B. ROOF TOP INSTALLATION

This type of installation is not recommended on wood

frame structures where low noise levels are required.

Supporting structure or platform for the unit must be level.

If installation is on a flat roof, locate unit minimum 6 inches

(152mm) above roof level.

Place the unit over one or more load bearing walls. If there

are several units, mount them on platforms that are

self

−

supporting and span several load bearing walls.

These suggestions are to minimize noise and vibration

transmission through the structure. If the structure is a

home or apartment, avoid locating the unit over

bedrooms or study.

NOTE:

When unit is to be installed on a bonded

guaranteed roof, a release must be obtained from the

building owner to free the installer from all liabilities.

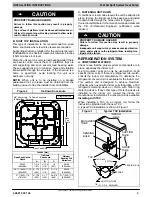

Figure 2

Tie Down Knockouts

Base

Pan

Depth

C

B

A

Base Pan Width

3/8”

(10mm)

dia. Tie Down Knockouts

In Base Pan (2 places)

View From Top

Inches (mm)

Base Pan Width x

Depth

Tie Down

Knockouts

Minimum

Mounting Pad

Dimensions

A

B

C

23x23

(584x584)

7

−

3/4

(197)

4

−

7/16

(113)

18

(457)

23x23

(584x584)

25

−

11/16x25

−

11/16

(652x652)

9

−

1/16

(230)

4

−

7/16

(113)

21

−

1/4

(540)

26x26

(660x660)

31

−

1/8x31

−

1/8

(791x791)

9

−

1/16

(230)

6

−

1/2

(165)

24

−

5/8

(625)

31

−

1/2x31

−

1/2

(800x800)

C. FASTENING UNIT DOWN

If conditions or local codes require the unit be attached in

place, remove the knockouts in the base pan and install

tie down bolts through the holes (refer to Figure 2).

Contact local distributor for hurricane hold

−

down details and

the P.E. (Professional Engineer) certification, when

required.

!

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Inadequate unit support may cause excessive vibration,

noise, and/or stress on the refrigerant lines, leading to re-

frigerant line failure.

REFRIGERATION SYSTEM

A. COMPONENT MATCHES

Check to see that the proper system components are in

place, especially the indoor coil.

R

−

410A outdoor units can only be used with R

−

410A

specific indoor coils. If there is a refrigerant mis

−

match,

consult the indoor coil manufacturer to determine if a

refrigerant conversion kit is available for the indoor coil.

This outdoor unit is designed to achieve maximum

efficiency when used with indoor coils that utilize a TXV

refrigerant metering device or Piston with Teflon ring

metering device. If any other type of metering device is

installed on the indoor coil, consult the indoor coil

manufacturer to determine if a conversion kit is available.

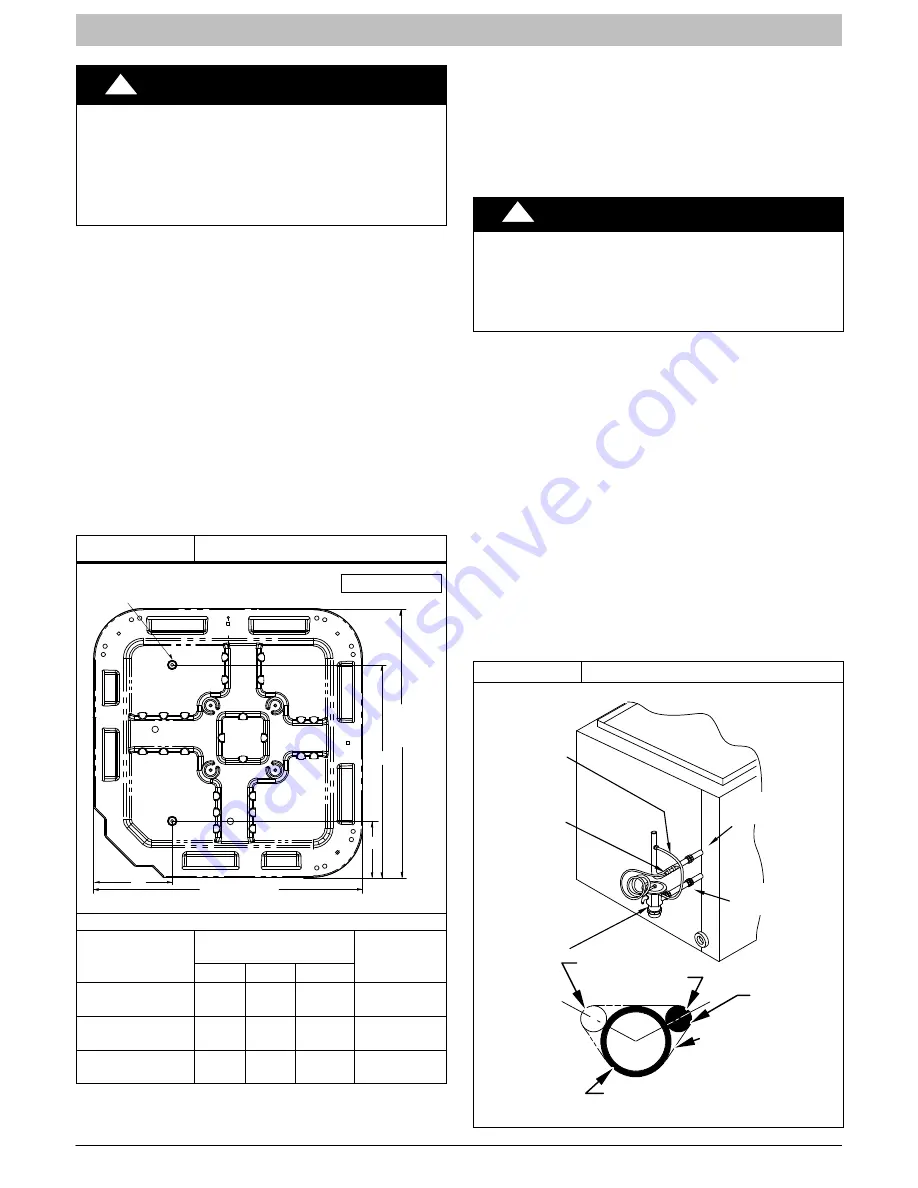

Installing with TXV.

When installing a TXV on an indoor coil, follow the

instructions provided with the new TXV.

A typical TXV installation is shown in Figure 1.

Figure 1

Typical TXV Installation

TXV

SENSING

BULB

EQUALIZER

TUBE

INDOOR

COIL

SUCTION

TUBE

LIQUID

TUBE

SENSING BUL

STRAP

SUCTION TUBE

IN. OD & SMALLER

10 O’Clock

2 O’Clock

7/8