INSTALLATION INSTRUCTIONS

R

−

410A Split System Heat Pump

4

428 01 5301 05

Specifications subject to change without notice.

Installing with Indoor Piston

−

cooling operation.

(Heat pumps also use an outdoor piston for heating

operation, refer to section F.)

Check piston size shipped with indoor unit to see if it

matches required indoor piston size shown on outdoor

unit rating plate.

If it does not match, replace indoor piston with

cooling

piston, according to size marked on outdoor unit rating

plate. (Some outdoor models include a cooling piston in

the accessory bag.)

Heating piston is shipped in the service valve

−

refer to

section F.

Example fan coils with piston: FEM4P, FSM4P, FSU4P,

FMA4P, FMC4P, FMU4P, WAPM, WAPT, WAPL, WAMA,

WAMC.

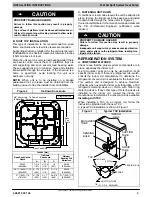

See Figure 2.

When changing indoor piston, use a back

−

up wrench.

Finger tighten hex nut, then tighten with wrench 1/2 turn.

Do not exceed 30 ft

−

lbs (40.7 N

−

m).The indoor piston

contains a Teflon ring (or seal) which is used to seat

against the inside of distributor body, and must be

installed properly to ensure proper seating in the direction

for cooling operation.

Figure 2

Indoor (cooling) Piston

TEFLON SEAL

BRASS

HEX NUT

STRAINER

PISTON

RETAINER

BRASS

HEX BODY

DISTRIBUTOR

PISTON

FLOW IN

COOLING

TEFLON RING

L10S017

!

CAUTION

PRODUCT OPERATION HAZARD

Failure to follow this caution may result in improper product

operation.

If using a TXV in conjunction with a single

−

phase reciprocat-

ing compressor, a compressor start capacitor and relay are

required. Consult outdoor unit pre

−

sale literature for start as-

sist kit part number.

B. REFRIGERANT LINE SETS

The refrigerant line set must be properly sized to assure

maximum efficiency and proper oil circulation.

Refer to Product Specifications and Long Line

Applications Guideline for line set sizing

.

NOTE:

Total line set length must not exceed 200 feet

(61m).

NOTE:

A crankcase heater must be used when the

refrigerant line length exceeds 80 feet (24.4m).

If outdoor unit is more than 10 feet (3m) higher than the

indoor coil, refer to the Long Line Applications Guideline

for instructions.

NOTE:

When the outdoor unit is higher than the indoor

coil, the vertical separation must not exceed 100 feet

(30m).

NOTE:

When the outdoor unit is lower than the indoor

coil, the vertical separation must not exceed 50 feet

(15.2m).

If it is necessary to add refrigerant line in the field, use

dehydrated or dry, sealed, deoxidized, copper

refrigeration tubing. Do not use copper water pipe.

Do not remove rubber plugs or caps from copper tubing

until connections are ready to be made.

Be extra careful when bending refrigeration tubing.

Tubing can “kink” easily, and if this occurs, the entire

length of tubing must be replaced.

!

WARNING

PERSONAL INJURY HAZARD

Failure to relieve system pressure could result in

personal injury and/or death.

Relieve pressure and recover all refrigerant before

servicing existing equipment, and before final unit

disposal. Use all service ports and open all flow

−

control devices, including solenoid valves.

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in improp-

er product operation.

Do not leave system open to atmosphere any lon-

ger than absolutely required for installation. Inter-

nal system components

−

especially refrigerant

oils

−

are extremely susceptible to moisture con-

tamination. Keep ends of tubing sealed during

installation until the last possible moment.

C. ROUTING AND SUSPENDING REFRIGERANT

LINES

Run refrigerant lines as straight and direct as possible,

avoiding unnecessary bends and turns. Always insulate

the entire suction line. Both lines should be insulated

when routed through an attic or when routed through an

underground raceway.