INSTALLATION INSTRUCTIONS

R

−

410A Split System Heat Pump

428 01 5301 05

5

Specifications subject to change without notice.

When routing refrigerant lines through a foundation or

wall, do not allow refrigerant lines to come in direct

contact with the building structure. Make openings large

enough so that lines can be wrapped with extra insulation.

Fill all gaps with RTV caulk. This will prevent noise

transmission between the tubing and the foundation or

wall.

Along floor or ceiling joists, suspend refrigerant lines so

that they do not contact the building structure, water

pipes, or ductwork. Use insulated or suspension type

hangers. Metal straps must be at least 1” (25mm)wide to

avoid cutting into the tube insulation. Keep the liquid and

suction lines separate. Refer to Figure 3.

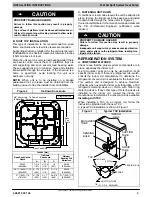

Figure 3

Routing and Suspending Refrigerant Lines

INSULATION

SUCTION TUBE

LIQUID TUBE

OUTDOOR WALL

INDOOR WALL

LIQUID TUBE

SUCTION TUBE

INSULATION

CAULK

HANGER STRAP

(AROUND SUCTION

TUBE ONLY)

JOIST

1” (25mm) MIN

THROUGH THE WALL

SUSPENSION

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in improp-

er product operation.

Do not bury more than 36” (1m) of line set under-

ground. Refrigerant may migrate to cooler buried

section during extended periods of unit shut

−

down, causing refrigerant slugging and possible

compressor damage at start

−

up.

If ANY section of the line set is buried under-

ground, provide a minimum 6” (152mm) vertical

rise at the service valve.

D. OUTDOOR UNIT HIGHER THAN INDOOR UNIT

Proper oil return to the compressor should be maintained

with suction gas velocity. If velocities drop below 1500

fpm (feet per minute), oil return will be decreased. To

maintain suction gas velocity, do not upsize vertical

suction risers.

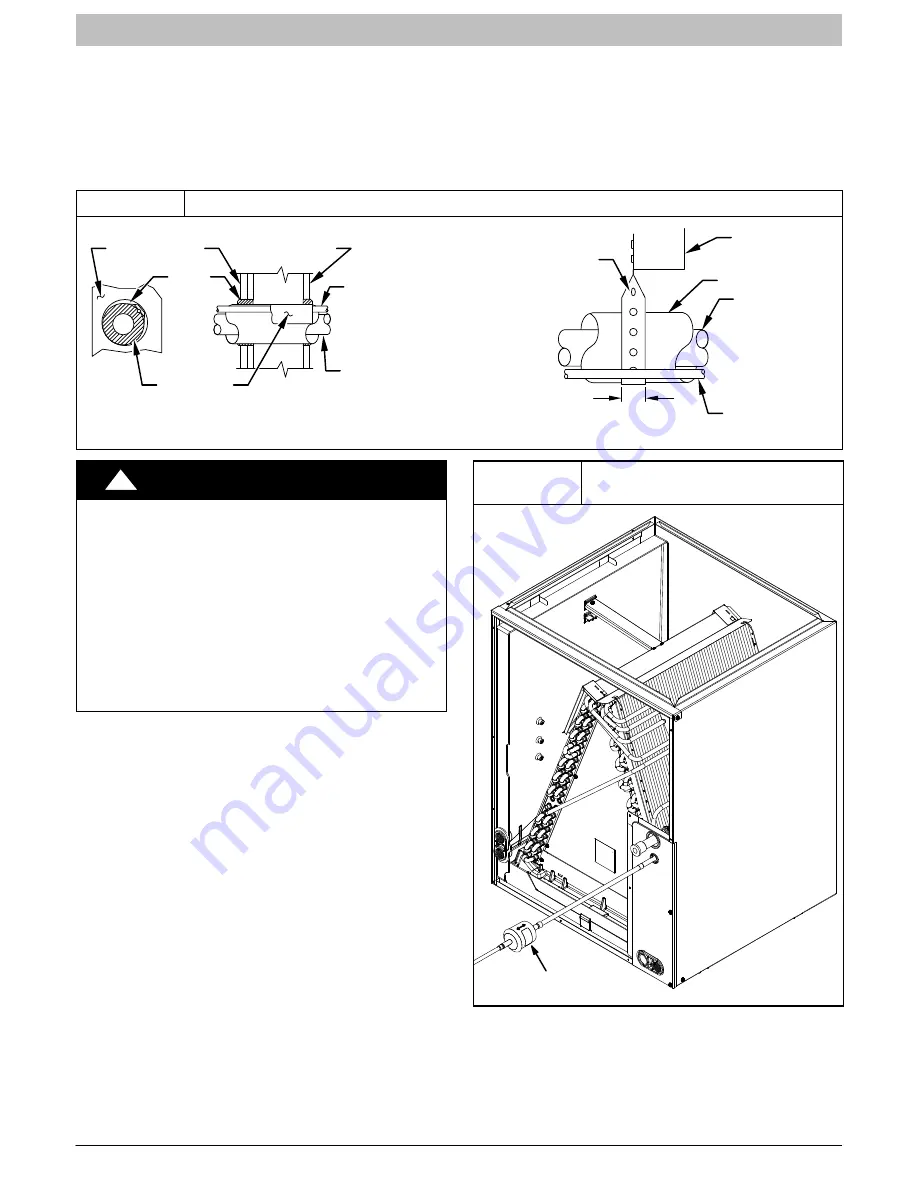

E. LIQUID LINE FILTER

−

DRIER

Outdoor units are shipped with an appropriate filter

−

drier

for installation in the liquid line. Leave the plugs in the tube

ends until the filter

−

drier is installed. The optimal location

for the filter

−

drier is close to the indoor coil. Heat pump

filter

−

driers are “bi

−

flow” type. Either end can be pointed

towards indoor coil. Refer to Figure 4.

Figure 4

Liquid Line Filter

−

Drier

Installed at Indoor Coil

38

−

11

−

84

Filter

−

Drier

F. SERVICE VALVES

Service valves are closed and plugged from the factory.

Outdoor units are shipped with a refrigerant charge

sealed in the unit. Leave the service valves closed until all

other refrigerant system work is complete or the charge