INSTALLATION INSTRUCTIONS

R

−

410A Split System Heat Pump

428 01 5301 05

7

Specifications subject to change without notice.

If vacuum must be interrupted during the evacuation

procedure, always break vacuum with dry nitrogen.

Deep Vacuum Method

The deep vacuum method requires a vacuum pump

capable of pulling a vacuum to 500 microns and a vacuum

gauge capable of accurately measuring this vacuum

level. The deep vacuum method is the most positive way

of assuring a system is free of air and water.

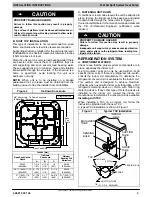

Watch the vacuum gauge as the system is pulling down.

The response of the gauge is an indicator of the condition

of the system (refer to Figure 6).

With no leaks in the system, allow the vacuum pump to

run for 30 minutes minimum at the deep vacuum level.

Triple Evacuation Method

The triple evacuation method should only be used when

system does not contain any water in liquid form and

vacuum pump is only capable of pulling down to 28 inches

of mercury (711mm Hg). Refer to Figure 7 and proceed is

as follows:

Figure 6

Deep Vacuum Gauge Response

and System Conditions

500

MINUTES

0

1

2

4

6

1000

1500

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

M

ICRONS

2500

3000

3500

4000

4500

5000

3

7

5

1. Pull system down to 28 inches of mercury (711mm

Hg) and allow pump to continue operating for an

additional 15 minutes.

2. Close manifold valves or valve at vacuum pump

and shut off vacuum pump.

3. Connect a nitrogen cylinder and regulator to

system and fill with nitrogen until system pressure

is 2 psig.

4. Close nitrogen valve and allow system to stand for

1 hour. During this time, dry nitrogen will diffuse

throughout the system absorbing moisture.

5. Repeat this procedure as indicated in Figure 7.

6. After the final evacuate sequence, confirm there

are no leaks in the system. If a leak is found, repeat

the entire process after repair is made.

Figure 7

Triple Evacuation Sequence

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

CHARGE SYSTEM

BREAK VACUUM WITH DRY NITROGEN

EVACUATE

WAIT

I. OPENING SERVICE VALVES

Outdoor units are shipped with a refrigerant charge

sealed in the unit. Opening the service valves releases

this charge into the system.

NOTE:

Open the Suction service valve first. If the Liquid

service valve is opened first, oil from the compressor may

be drawn into the indoor coil TXV, restricting refrigerant

flow and affecting operation of the system.

Remove Suction service valve cap and insert a hex

wrench into the valve stem. Hold the valve body steady

with an end

−

wrench and back out the stem by turning the

hex wrench counterclockwise. Turn the stem until it just

contacts the rolled lip of the valve body.

After the refrigerant charge has bled into the system,

open the Liquid service valve.

NOTE:

These are not back

−

seating valves. It is not

necessary to force the stem tightly against the rolled lip.

The service valve cap is a primary seal for the valve and

must be properly tightened to prevent leaks. Make sure

cap is clean and apply refrigerant oil to threads and

sealing surface on inside of cap.

Tighten cap finger tight and then tighten additional 6 of a

turn (1 wrench flat) to properly seat the sealing surfaces.

J. GAUGE PORTS

Check for leaks at the schrader ports and tighten valve

cores if necessary. Install plastic caps finger tight.