440 04 7113 02

17

Specifications subject to change without notice.

“Filter Arrangement” under the “Installation” section of this

manual.

CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never operate furnace without a filter or filtration

device installed. Never operate a furnace with filter or

filtration device access doors removed.

!

WARNING

NOTE

: If the filter has an airflow direction arrow, the arrow

must point toward the blower.

To clean or replace filters, proceed as follows:

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury or death, or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position and install a lockout tag. There may be more

than one disconnect switch. Lock out and tag switch

with a suitable warning label. Verify proper operation

after servicing.

!

WARNING

1. Turn off electrical supply to furnace.

2. Remove filter cabinet door.

3. Slide filter out of cabinet.

4. If equipped with permanent, washable filter, clean

filter by spraying cold tap water through filter in

opposite direction of airflow. Rinse filter and let dry.

Oiling or coating of the filter is not recommended.

5. If equipped with factory specified disposable media

filter, replace only with a factory specified media filter

of the same size.

6. Slide filter into cabinet.

7. Replace filter cabinet door.

8. Turn on electrical supply to furnace.

Blower Motor and Wheel Maintenance

To ensure long life, economy, and high efficiency, clean

accumulated dirt and grease from blower wheel and motor

annually.

The inducer and blower motors are pre--lubricated and

require no additional lubrication. These motors can be

identified by the absence of oil ports on each end of the

motor.

The following items should be performed by a qualified

service technician. Clean blower motor and wheel as

follows:

1. Turn off electrical supply to furnace.

2. Remove blower door.

3. All factory wires can be left connected, but field

thermostat and accessory wiring may need to be

disconnected depending on their length and routing.

4. If the vent and combustion air pipe passes through

the blower compartment, it will be necessary to

remove the pipes from the blower compartment.

Disconnect the vent and combustion air pipe by:

a. Loosen the clamps on the vent couplings and

combustion air pipe external to the furnace.

b. Separate the pipes from the couplings and move

them aside.

c. Loosen the clamps on the vent couplings and

combustion air pipe located on the blower shelf.

d. Separate the pipes from the blower compartment

and set aside.

e. Remove the couplings from the pipe adapters and

set aside.

f. After servicing the blower, reverse steps a through

e.

g. Tighten all clamps 15 lb --in.

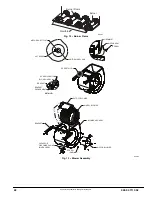

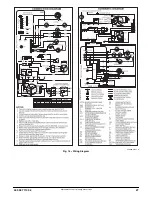

See Fig. 13 for steps 5 through 14.

5. Remove screws securing blower assembly to blower

shelf and slide blower assembly out of furnace.

Detach ground wire and disconnect blower motor

harness plugs from blower motor.

NOTE

: Blower wheel is fragile. Use care.

6. Clean blower wheel and motor by using a vacuum

with soft brush attachment. Be careful not to disturb

balance weights (clips) on blower wheel vanes. Do

not bend wheel or blades as balance will be affected.

7. If greasy residue is present on blower wheel, remove

wheel from the blower housing and wash it with an

appropriate degreaser. To remove wheel:

a. Mark blower wheel location on shaft before

disassembly to ensure proper reassembly.

b. Loosen setscrew holding blower wheel on motor

shaft.

NOTE

: Mark blower mounting arms and blower housing so

each arm is positioned at the same hole location during

reassembly.

c. Mark blower wheel orientation and cutoff plate

location to ensure proper reassembly.

d. Remove screws securing cutoff plate and remove

cutoff plate from housing.

e. Remove bolts holding motor mounts to blower

housing and slide motor and mounts out of housing.

f. Remove blower wheel from housing.

g. Clean wheel per instructions on degreaser cleaner.

Do not get degreaser in motor.

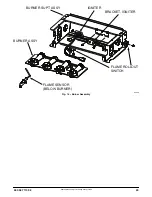

8. Reassemble motor and blower wheel by reversing

items 7b through 7f. Ensure wheel is positioned for

proper rotation.

9. Torque motor mounting bolts to 40 +/-- 10 lb--in. when

reassembling.

10. Torque blower wheel set screw to 160 +/-- 20 lb--in.

when reassembling.

11. Verify that blower wheel is centered in blower housing

and set screw contacts the flat portion of the motor

shaft. Loosen set screw on blower wheel and

reposition if necessary.

12. Spin the blower wheel by hand to verify that the wheel

does not rub on the housing.

13. Reinstall blower assembly in furnace.

14. Reinstall 2 screws securing blower assembly to

blower deck.

15. Reconnect blower leads to furnace control. Refer to

furnace wiring diagram, and connect thermostat leads

if previously disconnected.