1.

Open barbecue hood before attempting to light

back burner.

2.

Set burner control knobs to

‘OFF’

and open the

gas cylinder valve.

3.

Push and turn back burner control knob to

‘ON’

.

4.

Then immediately press the continuous spark

igniter for 3 - 4 seconds to light the burner.

5.

If the burner does not light, turn the control knob

to

‘OFF’

, wait 5 minutes, then retry.

6.

Once the burner is ignited, the back burner will

reach cooking temperature quickly. The orange

/ red glow will even out in about 5 minutes.

7.

For best results, always rotisserie cook with the

hood down.

NOTE: If extra heat is required, then any of

the main burners may be used on the ‘LOW’

setting only. Do not exceed 250º with hood

closed.

NOTE: The location of the back burner makes it

more susceptible to wind conditions that will

decrease the performance of your rotisserie cooking.

For this reason you should not operate the back

burner during windy weather conditions.

BACK BURNER IGNITION

1.

Open barbecue hood before attempting to light burners.

2.

Set burner control knobs to

‘OFF’

and open the

gas cylinder valve.

NOTE: Upon first assembly the gas

lines and burners will be full of air.

In order for the burners to light

properly the lines must fill with gas.

It may require several attempts at

lighting the burners before you are

successful.

3.

Push and turn the required burner control knob to

‘HI’

.

4.

Immediately press the continuous spark igniter for up to 15

seconds to light the burner.

5.

If the burner does not light, turn the burner control knob to

‘OFF’

, wait 5 minutes for gas to clear, then retry.

6.

Once the burner is ignited, the adjacent burner can be lit by

simply turning its control knob to ‘

HI’

.

7.

Adjust burner control knobs to your desired cooking

temperature.

8.

If ignition cannot be achieved, perform ignition check

procedure.

Refer to pages 12 and 13.

MAIN BURNER IGNITION

1.

Open side burner lid before attempting to light side burner.

2.

Set burner control knobs to

‘OFF’

and open the

gas cylinder valve.

3.

Push and turn the control knob anti-clock-

wise until a “click” is heard

.

4.

Immediately the piezo igniter will be triggered

to light the burner.

5.

If the burner does not light, turn the control

knob to

‘OFF’

, wait 5 minutes, then retry.

6.

Adjust burner control knob to desired flame level.

SIDE BURNER IGNITION

O

P

E

R

A

T

I

O

N

14

14

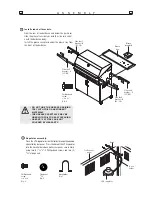

Before first use and at the beginning of each barbecue season:

1.

Please read

Safety, Lighting and Operating instructions

care-

fully.

2.

Check gas valve orifices, burner tubes and burner ports for

any obstructions.

eg. spiders, webs, insects.

3.

Check and ensure the gas cylinder is full.

4.

Ensure all connections are securely tightened.

Check for gas leaks.

See pages 3.

NOW YOUR BARBECUE IS READY TO USE

The temperature gauge is used as a guide to cooking temperatures

when cooking with the hood closed.

When an opening is provided in the

hood, this allows for the installation of

the temperature gauge.

Install as shown in

the diagram, if not factory fitted.

TEMPERATURE GAUGE

CAUTION: IF BURNERS GO OUT DURING

OPERATION, CLOSE GAS SUPPLY AT

SOURCE, AND TURN ALL BURNER

CONTROLS OFF.

OPEN HOOD AND WAIT 5 MINUTES

BEFORE RE-ATTEMPTING TO LIGHT

(ENSURE ACCUMULATED GAS FUMES

HAVE CLEARED).

CAUTION: SHOULD A GREASE FIRE

OCCUR, ATTEMPT TO CLOSE GAS SUPPLY

AT SOURCE, TURN OFF ALL BURNERS AND

REMOVE FOOD IF POSSIBLE.

KEEP THE VENTILATION OPENINGS OF

THE CYLINDER ENCLOSURE FREE AND

CLEAR FROM DEBRIS.

THE HOOD MUST BE IN THE OPEN

POSITION FOR LIGHTING.

DO NOT SMOKE AT ALL TIMES WHEN

ATTEMPTING TO IGNITE BARBECUE.

CAUTION: DO NOT MOVE TROLLEY WHILE

BARBECUE IS IN OPERATION.

THE SIDE BURNER IS DESIGNED FOR USE

WITH A WOK UP TO 360 mm DIAMETER,

AND COOKING PAN OF UP TO 200 mm

DIAMETER.

USE OF VERY LARGE POTS MAY RESULT

IN DISCOLOURATION OF THE SURFACE

FINISH, OR CAUSE POOR COMBUSTION.