• SHOULD A FLASHBACK FIRE OCCUR

IN OR AROUND THE BURNER TUBES,

FOLLOW THE INSTRUCTIONS BELOW.

FAILURE TO COMPLY WITH THESE

INSTRUCTIONS COULD RESULT IN A

FIRE OR EXPLOSION THAT COULD

CAUSE SERIOUS BODILY INJURY,

DEATH, OR PROPERTY DAMAGE

• SHUT OFF GAS SUPPLY TO THE GAS

BARBECUE

• TURN THE CONTROL KNOBS TO OFF

POSITION

• OPEN THE BARBECUE LID.

PUT OUT ANY FLAME WITH A FIRE

EXTINGUISHER

• ONCE THE BARBECUE HAS COOLED

DOWN, CLEAN THE BURNER TUBES

AND BURNERS ACCORDING TO THE

CLEANING INSTRUCTIONS IN THIS

OPERATOR'S MANUAL.

1.

Turn gas off at source and turn burner control knobs to

‘OFF’

. Wait at least five (5) minutes for gas to clear, then

retry.

2.

If your barbecue still fails to light, check gas supply and

connections.

3.

Repeat lighting procedure. If your barbecue still fails to

operate, turn the gas off at source, turn the control knobs to

‘OFF’

, then check the following:

•

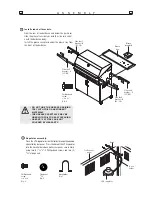

Misalignment of burner tubes over orifices

Correction:

Reposition burner tubes over orifices.

•

Obstruction in gas line

Correction:

Remove fuel line from barbecue. Do not smoke!

Open gas supply for one second to clear any obstruction

from fuel line. Close off gas supply at source and reconnect

fuel line to barbecue.

•

Plugged orifice

Correction:

Remove burners from barbecue by pulling cotter

pin (beneath burner) using long nose pliers. Carefully lift

each burner up and away from gas valve orifice. Remove

the orifice from gas valve and gently clear any obstruction

with a fine wire. Then reinstall all orifices, burners, cotter

pins and cooking components.

If an obstruction is suspected in gas valves or manifold,

contact your place of purchase or manufacture.

•

Obstruction in burner tubes

Correction:

Follow the burner tube cleaning procedure

on page 20 of this operator's manual.

•

Misalignment of igniter on burner

Correction:

Check for proper position of the electrode tip as

shown on pages 12 and 13. The gap between the spark

electrode tip and spark receiver should be approximately

4 - 5 mm. Adjust if necessary. With the gas supply closed

and all control knobs set to

‘OFF’

press the electronic igniter

cap and check for the presence of a spark at the electrode.

•

Disconnected electronic wires

Correction:

Inspect the igniter junction box found behind the

control panel. Connect loose electronic wires to junction

box and try to light the barbecue.

•

Weak AA battery

Correction:

Unscrew the igniter cap and replace the battery.

IF THE BARBECUE FAILS TO LIGHT

CAUTION: If burners go out during operation, close

gas supply at source, and turn all gas valves off.

Open hood and wait 5 minutes before re-attempting

to light (this allows accumulated gas fumes to

clear).

CAUTION: Should grease fire occur, close gas supply

at source, turn off all burners and remove food until

fire is out.

KEEP THE VENTILATION OPENINGS OF THE

CYLINDER ENCLOSURE FREE AND CLEAR FROM

DEBRIS.

F

A

U

L

T

F

I

N

D

I

N

G

17

17