33

32

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: rjones@grangemachinery.co.uk

W: www.grangemachinery.co.uk

Grange Machinery Ltd.

Sproatley Grange

Hull

HU11 4PT

M: 07918 515385

T: 01482 815711

E: rjones@grangemachinery.co.uk

W: www.grangemachinery.co.uk

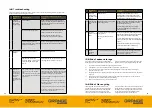

Example of

failure

Possible causes

Investigation to address root causes

of failure.

1.0 Inability to

achieve rapid

entry of soil

engaging legs.

Points are worn.

Replace points according to soil profile and

equipment usage. Contact Grange Machinery

Ltd personnel for sourcing replacements and

additional spares.

Incorrect linkage configuration.

Is the machine raising and lowering on the

linkage parallel to the rear of the tractor?

Review tractor linkage adjustments in

accordance with manufacturer’s guidance.

Tractor hydraulic pressure is

insufficient or flow rates / response

times require adjustment.

Review tractor hydraulic system and settings in

accordance with manufacturer’s guidance.

2.0 Hydraulic oil

leakage

Tighten up hydraulic fittings

General operation routines

Hydraulic ram seals need

replacing. Before removing rams

contact Grange Machinery Ltd

directly.

Check that the ram bores aren’t scored and

causing premature failure of the seals.

3.0 Inadequate

performance

of 2nd stage

soil engaging

equipment

which is

coupled up to

the Grange 3m

LDT.

Check hitch / linkage connection

position on rear of Grange 3m

LDT.

Check hydraulic connections and

flow settings through to auxiliary

equipment.

Set-up the tillage configuration in the field in

the working position, isolate the tractor engine,

secure the handbrake. Check all adjustment

variables and depth of soil penetration.

Check all equipment settings in accordance

with soil profile.

Check wearing parts and refer to operator’s

manual for connection 2nd stage cultivation/

seeding equipment.

Check tractor tyre pressures and front ballast.

If required refer to Grange Machinery Ltd

personnel for further advice.

This section provides the operator with a reference in the event of experiencing difficulty in operational

mode and in the event of component failure.

14.0 Troubleshooting

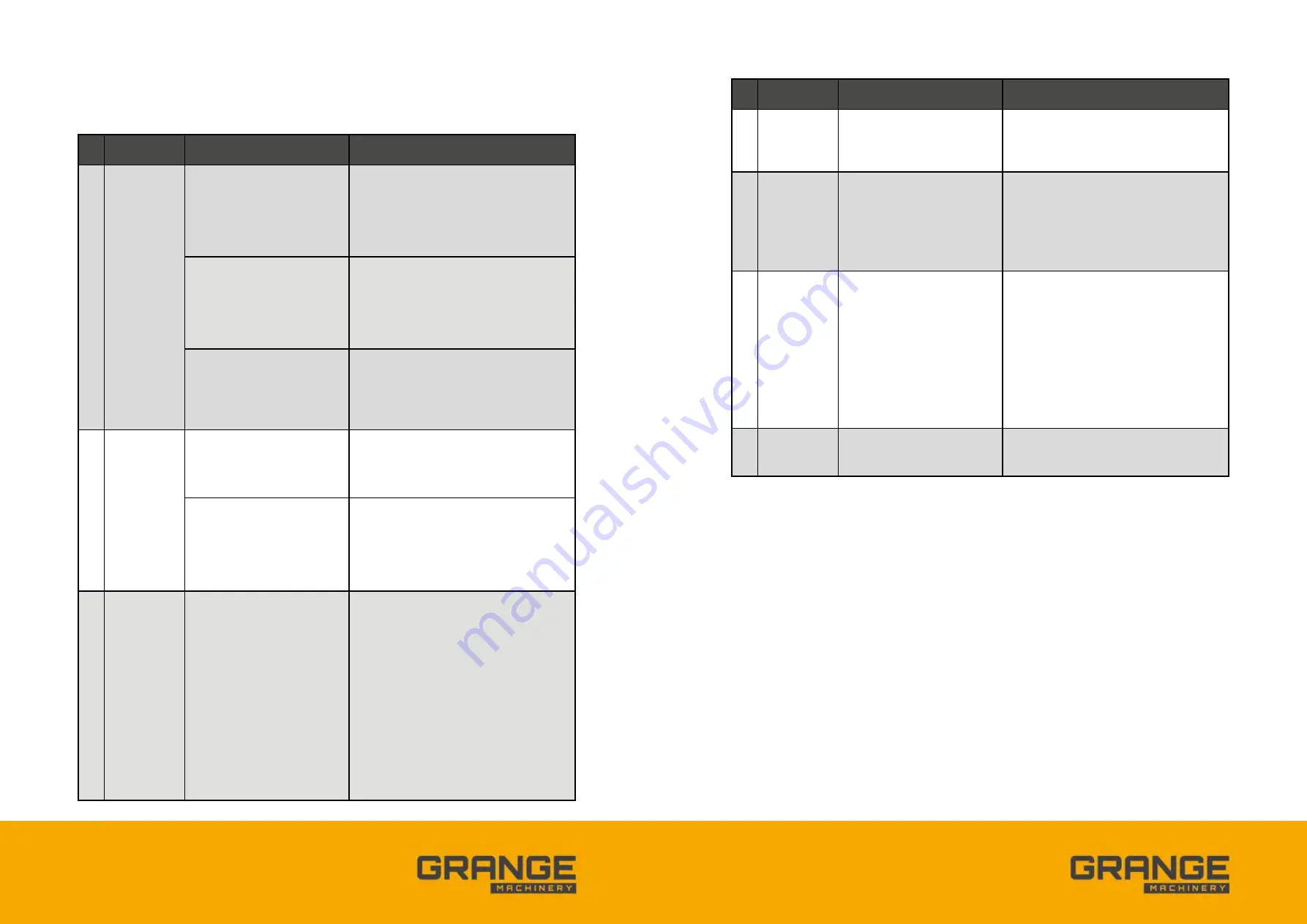

Example of

failure

Possible causes

Investigation to address root causes

of failure.

4.0 Discs stop

rotating when

engaged in the

ground.

Bearing failure.

Bearings are sealed although do have a

finite life. Remove disc section and contact

Grange Machinery Ltd personnel for sourcing

replacements and additional spares.

5.0 Trash building

up around the

legs.

Discs have lost their cutting edge

and need replacing.

Replace discs. Check all discs for wear and plan

to replace in sections to maintain a constant

profile across the machine.

Contact Grange Machinery Ltd personnel

for sourcing replacement disc sections and

additional spares.

6.0

Repeated

failure of shear

bolts.

Incorrect shear bolt specification

and tightness.

Main leg assembly bolts are

loose.

Check the leg points for wear. Using the points

beyond their useful wear life will put excessive

stress on the shear bolts. Replace points.

Contact Grange Machinery Ltd personnel for

sourcing replacement shear bolts and additional

spares.

Check the shear bolt locating section for any

signs of elongated holes or loose fitting.

Tighten main leg assembly bolts.

7.0 Uneven

cultivation

depth

Incorrect lower link arm settings

Check lower link arm settings on the tractor

and adjust in accordance with tractor

manufacturer’s guidance.

15.0 End of season storage

At the end of the working season, undertake the

following maintenance procedures. Ensure that the

machine is lowered to the ground, the hand brake

applied, tractor engine stopped and key removed.

i)

Dry brush and remove extraneous soil and vegetation matter.

ii)

If the points or discs need replacing follow the procedure in Section 13.0.

iii)

Check shear bolts for signs of excessive shear loadings and replace if necessary following the

procedure in Section 13.0.

iv)

Check hydraulic hoses, couplings and ram seals for evidence of leaks and excessive wear. Replace as

required.

v)

Apply anti-corrosion oils or grease to all wearing parts and exposed hydraulic cylinder rods and

linkage connections. Grease all pivot points liberally.

vi)

Park on hard standing in a dry covered storage area.

16.0 End of life recycling

The Grange 3m LDT is manufactured from

predominantly steel components with hydraulic

pipes and activating rams. Once the Grange 3m

LDT has completed its working life, the steel

can be recycled via an authorised outlet. Where

components have been in contact with hydraulic oil

they will need to be disposed of via an appropriate

hazardous waste recycling outlet. If you are unsure

of the correct disposal method please contact

Grange Machinery Ltd for further advice.