CRF-1 Operating Manual

Page 22 of 60

33801-V4 DMN S90

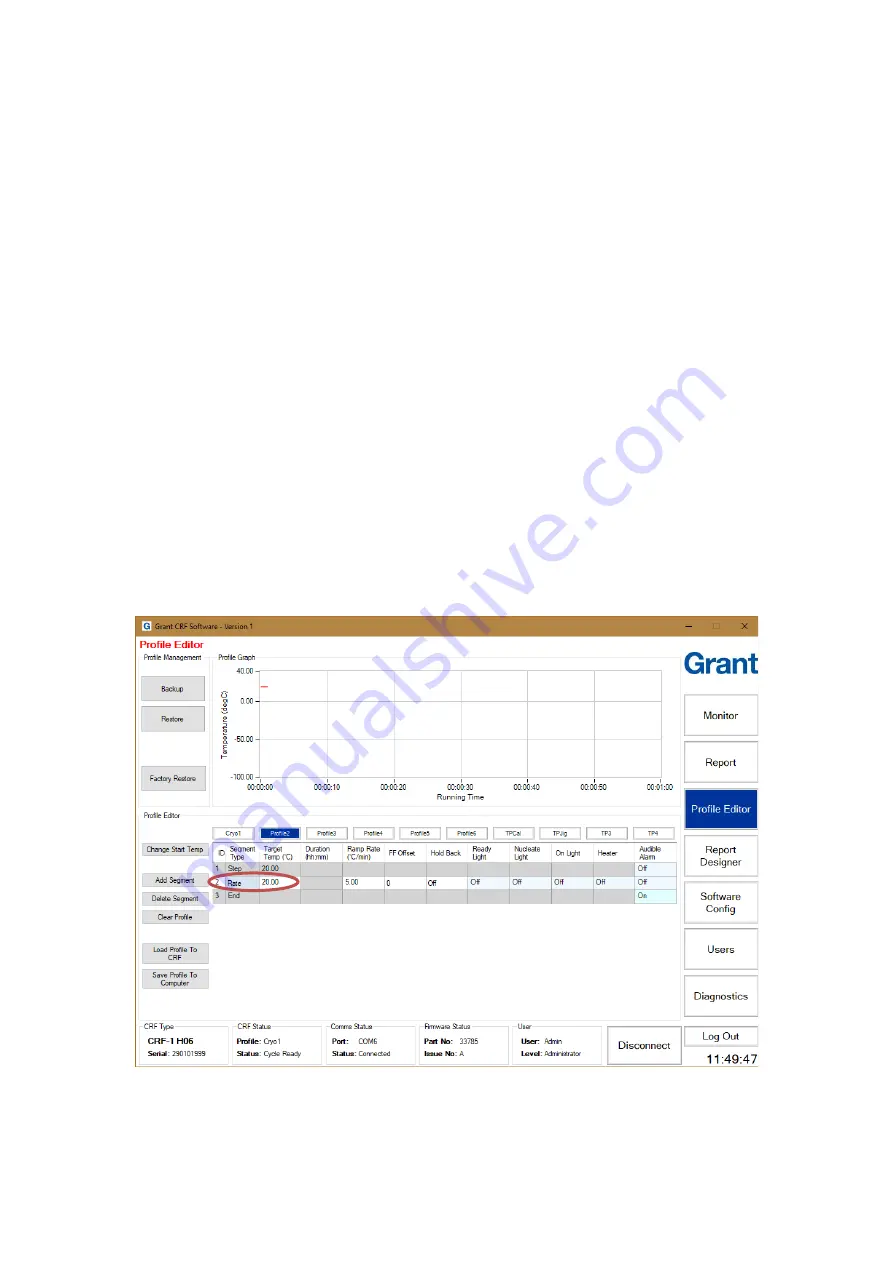

Figure 20: Software: Profile Editor

6.5.1. Editing an existing profile

The following sections provide information about how to change cooling profiles.

Note: When connected to a CRF-1 the changes made in the software are applied immediately

to the cryocooler. Backups of all profiles or individual profiles should be created before

making any significant changes.

6.5.1.1. Changing the start temperature

Note: It is only possible to have one start temperature for all profiles and changing this value

will update all profiles. Care and consideration should be taken before changing this

parameter.

Click

Change Start Temp

to change the universal profile start temperature. Update the

Start

Temp

box with the required value and click

Set Temp

in the

Set Start Temp

dialog box. Click

OK

in the

Confirm

dialog box to apply the change to all profiles.

6.5.1.2. Adding a segment

Click the segment

ID

box to highlight the segment position

where the new segment is to be

placed. Click

Add Segment

. A new

Rate

segment will always be added after the segment

that is highlighted (see Figure

21) except when the last segment is selected, in which case

the new segment is added before the end. The segment type can be changed after the

segment has been added.

Figure 21: Software: Profile Editor

– Adding Segment

Summary of Contents for CRF-1 H00

Page 1: ...Controlled Rate Freezer CRF 1 Series Operating Manual...

Page 59: ......