36

9. Commissioning

It is important that the following commissioning

procedure is carried out to ensure safe and

efficient operation of the boiler.

9.1 Equipment required

To carry out a complete and comprehensive

commissioning of the Grant wood pellet boiler

the following equipment is required.

Draught meter.

Flue gas analyser

–with a specific “wood pellet”

setting.

Container of at least 1 litre capacity.

9.2 Before switching on

1.

Open front access cleaning door and check ash

pan is empty and positioned on the base of the

combustion chamber, check the baffle (located

in the top of the combustion chamber) is secured

correctly on fixing brackets. Close the front

access cleaning door.

Fig. 9.1

2.

Check boiler flow and return are adequately

vented. Check boiler and heating system has

been vented (and pressurised if sealed

system).Check the wash down manifold has

been fitted and connected to an uninterrupted

main water supply with all valves open.

3.

Remove boiler top panel and boiler top access

doors. Check that the spiral baffles in both the

primary and secondary heat-exchangers are in

place.

4.

Test the boiler cleaning function by operating the

momentary „CLEANING‟ „TEST‟ switch on the

boiler control panel.

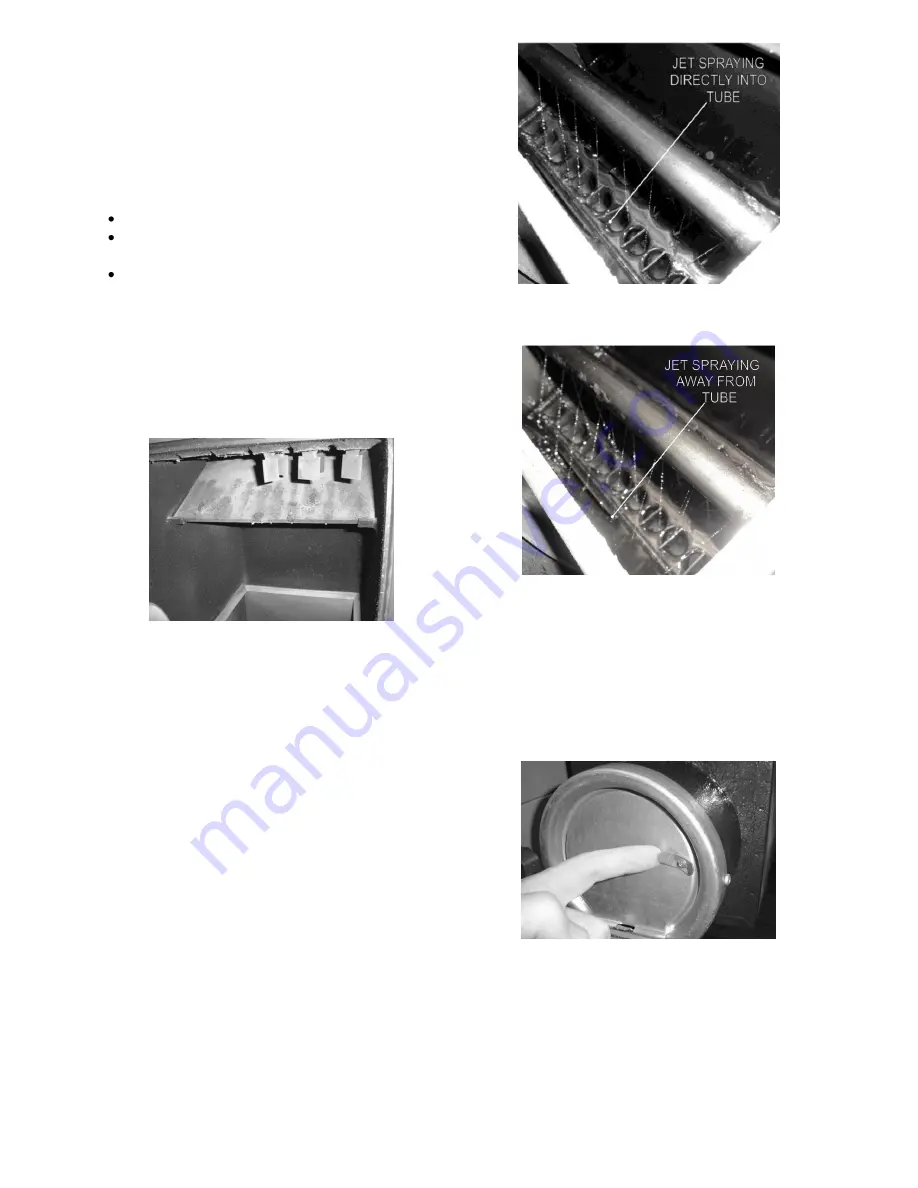

(a) Check the wash system (located under the top

rear access door) is spraying water directly into

each flue gas tube of the unit. If the water jets

are not spraying directly into the flue gas tubes

adjust the orientation of the wash pipe using the

screw in the right-hand side panel (above the

wash pipe on the right-hand side panel.)

Jets spraying correctly

Fig. 9.2

Jets spraying incorrectly

Fig. 9.3

(b) Check the shaker unit (located under the top

front access door) is operating freely and that

the spirals are moving up and down with an

intermittent sudden vertical motion.

5.

Refit the top access cleaning doors in position

and tighten nuts.

6.

Check the draught stabilizer is unobstructed and

the stopper is in the fully open position.

Fig. 9.4

7.

Check the quality of the wood pellets to be used

(see section 3 Pellet specification and storage).

Do not use wood pellets that have not being

approved By Grant Engineering (IRL) Ltd. for

use with this boiler.

Summary of Contents for Spira 6-26kW

Page 3: ...3 Grant SPIRA Condensing Wood Pellet Boiler Intermediate Hopper ...

Page 26: ...26 NO 1 NO 2 NO 3 GRANT WOOD PELLET 6 26 9 36 BURNER WIRING DIAGRAM FIGURE 7 4 ...

Page 53: ...53 12 Spare parts 12 1 Burner Burner controls Exploded view Fig 12 1 ...

Page 54: ...54 Burner Brazier Exploded view Fig 12 2 ...

Page 56: ...56 12 2 Boiler Exploded view Fig 12 3 SPIRA 6 26 boiler displayed Boiler parts list ...