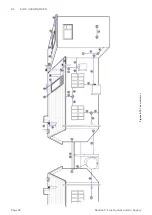

Section 9: Flue System and Air Supply

Page 31

! NOTE !

The Grant Orange system flexible stainless steel liner

is directional. The arrows marked on the liner MUST be

pointing vertically upwards, following the direction of the

flue gases. Failure to comply with this instruction could

lead to a leakage of condensate from the flue liner.

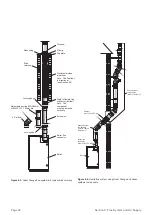

If a rigid flue is used externally, it must be of the twin-wall type,

to reduce the possibility of the condensate freezing in the flue,

incorporating seals at all joints, constructed with a stainless steel

inner skin and be suitably insulated and weatherproofed. The

internal flue diameter for a rigid flue for all Blue Flame models is

100 mm (4 in).

For a rigid conventional flue system Grant recommends the use

of the Grant ‘Hybrid’ flue system, which uses the Grant Green

and Orange flue system components for this application. Refer to

Section 1.3 for details.

! NOTE !

As no flue adaptor is supplied with the boiler, in order to

correctly connect the hybrid system, it will be necessary

to purchase the Grant CF adaptor kit (product code:

CFA15/70).

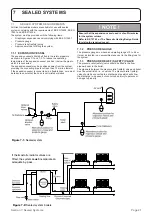

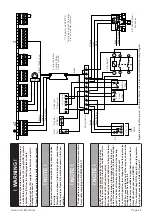

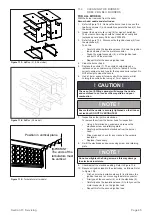

If required, it is possible to use the white painted single-wall

straight flue extensions, adjustable extensions and elbows from

the Grant ‘Orange’ system for the internal section of the flue

system, see Figure 9-3. These components can be fitted between

the boiler connector and flue adaptor. The flue adaptor, to which

the external twin-wall ‘Green’ flue components are connected, can

therefore be situated just before the flue system passes through

the wall. See Figure 9-4.

! NOTE !

Grant ‘Orange’ system single-wall flue components must

not be used externally.

The maximum vertical height (from the top of the boiler to the

terminal) for the 100 mm diameter hybrid ‘Green/Orange’ system

is 19 metres.

Grant ‘Green’ twin-wall flue is recommended for externally run

flues to reduce the possibility of the condensate freezing in the

flue.

No part of any flue system should be made of an asbestos

material; aluminium must not be used in any part of the flue.

Only stainless steel flue components should be used.

If the draught conditions are satisfactory, the flue should terminate

with a standard cowl.

Refer to the locally applicable Building Regulations, BS 5410:1

and OFTEC Installation Requirements (OFTEC Technical Books 2

and 4) for further guidance on conventional flue systems.

! CAUTION !

It is important to ensure that the flue system is sealed and

that condensate cannot escape. Up to 1.5 l/h of condensate

can be produced in a conventional flue system.

Do not use fire cement. The use of high temperature

silicone sealants is recommended.

! NOTE !

To comply with the requirements of the Building

Regulations Approved Document J - conventional flue

systems must have a flue data plate. A suitable data plate

is supplied with the Grant Orange flue system and should

be displayed next to the boiler or flue.

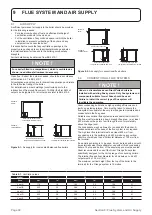

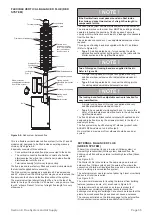

FLUE LINING KITS

Grant EZ-Fit Flexi Pack conventional flue system (Orange

System)

A range of Flexi pack conventional flue lining kits are available

from Grant UK. The packs have been specifically produced for

Grant Vortex oil fired condensing boilers.

The pack includes a terminal/top plate/flexi flue adaptor, stainless

steel smooth bore flexible flue liner, a rigid to flexi adaptor and a

boiler flue connector.

100mm Flue Lining components are suitable for use on all Grant

VortexBlue Internal models.

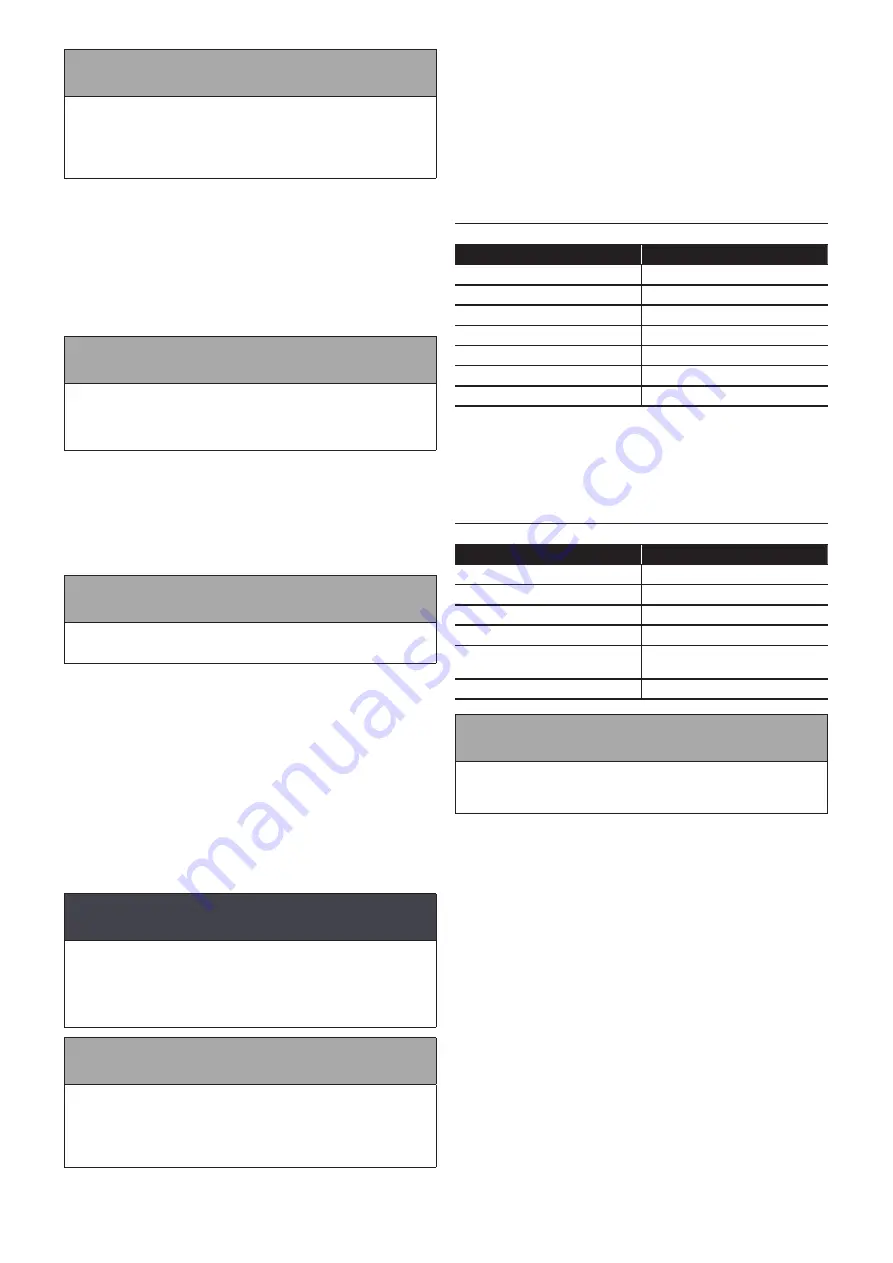

Table 9-2:

Conventional flue kits

Product code

Flexi pack (Orange system)

GFKIT 6/100

100 mm diameter x 6 metre

GFKIT 8/100

100mm diameter x 8 metre

GFKIT 10/100

100mm diameter x 10 metre

GFKIT 11/100

100mm diameter x 11 metre

GFKIT 12/100

100mm diameter x 12 metre

GFKIT 14/100

100mm diameter x 14 metre

GFKIT 16/100

100mm diameter x 16 metre

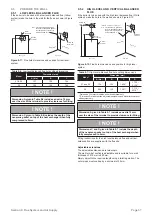

Extensions

A range of white powder coated single wall extensions are

available to connect the boiler to the flexible liner.

The nominal diameter of the extensions is 100 mm.

Extensions are supplied with locking bands.

Table 9-3:

Extensions

Product code

Extensions (Orange system)

WX 150/100

100 mm diameter x 150 mm

WX 250/100

100 mm diameter x 250 mm

WX 450/100

100 mm diameter x 450 mm

WX 950/100

100 mm diameter x 950 mm

WXA 250/100

100 mm diameter adjustable

extension (235 to 300 mm)

WE 45/100

100 mm diameter 45° elbow

! NOTE !

The rigid flue between the boiler and flexible flue liner

should incorporate an adjustable section to allow

inspection and cleaning of the flue system.