9

PHOTOVOLTAIC MODULES SAFETY

AND INSTALLATION MANUAL Rev. K

VALID IN NORTH AMERICA ONLY

Valid from September 2010

1305 S. Bertelsen Road Eugene, OR 97402

www.grapesolar.com

Tel: 1-877-264-1014 (toll free), 1-541-349-9000, Fax: 1-541-343-9000

nut (with torque less than 4N•m). Grounding wire should be directly connected with the

screw.

4.4

The rack must also be grounded unless they are mechanically connected by nuts and bolts to the

grounded PV modules. The array frame shall be grounded in accordance with NEC Article 250.

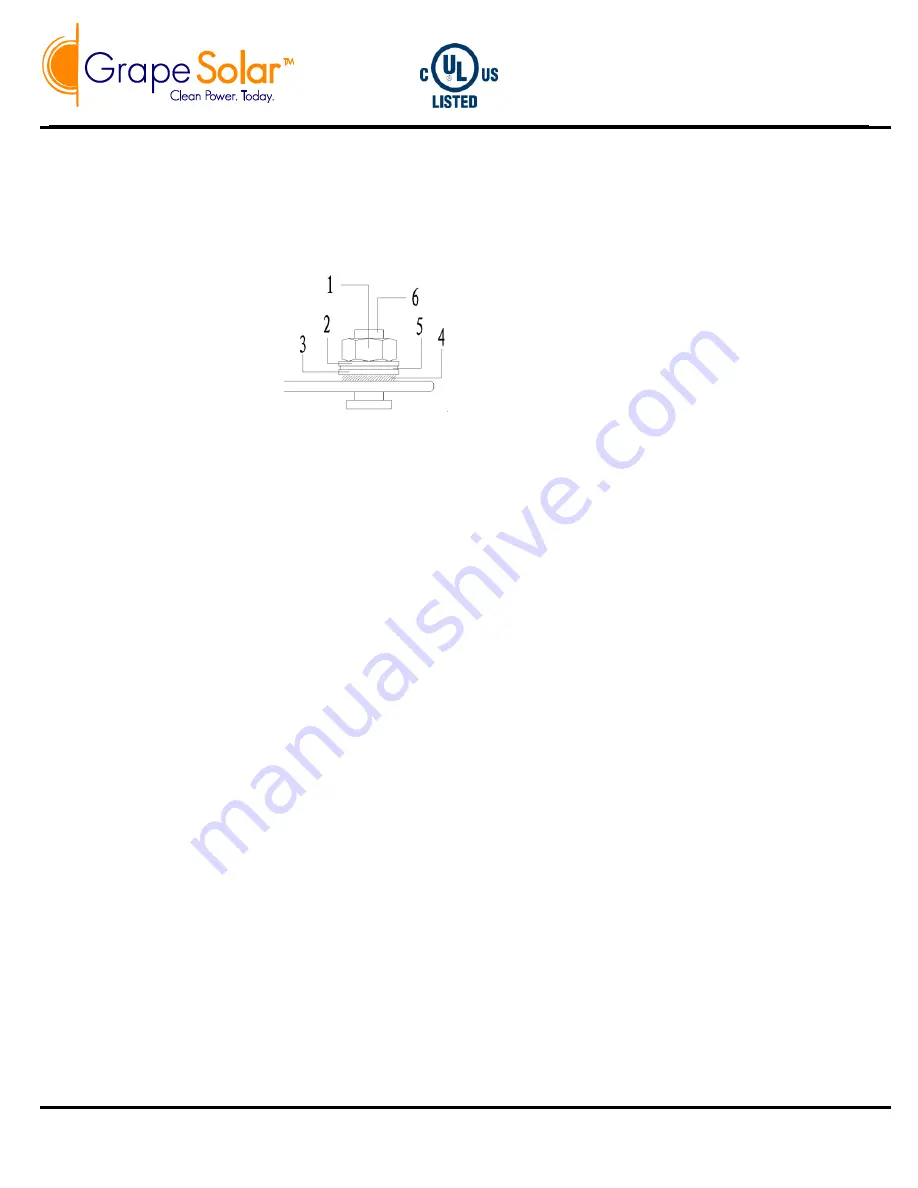

Figure-1 Grounding panel frame with stainless steel grounding & bonding equipment

5.

Mounting

5.1

The modules have been evaluated by UL for a maximum positive or negative design loading of

30 lbs/ft

2

. The maximum load on the module must not exceed 2400 Pascal (50 lbs/ft

2

).

5.2

Each module must be securely fastened at a minimum of 4 points using support frames or

mounting kits specialized for PV applications.

5.3

Panels may be mounted at any angle from vertical to horizontal orientation. However, to obtain

maximum yield from the PV system, the direction and tilt angle for the modules shall be set to

receive the incident sunlight perpendicularly to the module surface.

5.4

For roof mounted systems, at least a 2 inch clearance is required between the module back

surface and roof for rear ventilation and module cooling.

5.5

Clearance of a quarter inch or more between modules is required to allow for thermal expansion

of the frames.

5.6

Keep the back surface of the module free from any foreign objects or structural elements which

could come into contact with the module, especially when the module is under mechanical load.

5.7

To prevent water from entering the junction box, which could result in a safety hazard, modules

should not be mounted with the front/top glass facing downward.

5.8

Clearance between the module frames and structure or ground is required to prevent wiring

1

Stainless steel M5 nut

2

Stainless steel cupped M5 washer

3

Stainless steel flat M5 washer

4

Stainless steel M5 serrated washer

5

Grounding lead

6

Stainless steel M5 bolt