2635 W. 7

th

Place, Eugene, Oregon 97402, USA

11

Valid from February 2017

www.grapesolar.com

11 Tel: 1-877-264-1014 (toll free), 1-541-349-9000, Fax: 1-541-343-9000

PHOTOVOLTAIC MODULES SAFETY

AND INST

ALLATION MANUAL Rev.

P

VALID IN NORTH AMERICA ONLY

5.7

To prevent water from entering the junction box, which could result in a safety hazard, modules

should

not

be mounted with the front/top glass facing downward.

5.8

At least a 4 inch clearance between the module frames and structure, or wall, or ground is

required to prevent wiring damage and allows air to circulate behind the module.

5.9

PV modules can be mounted to the structure by the following methods:

5.9.1

Mounting Holes: Secure the module to the structure using the mounting holes. There are 8

mounting holes on module frame which have been evaluated by UL for mounting. Attach

¼ -20 x 0.75” stainless steel screw via each mounting hole with ¼” stainless steel flat

washer, and secure from behind with another stainless steel flat washer, local washer and

nut. Torque the bolts to 6.3ft lbs (8.5Nm).

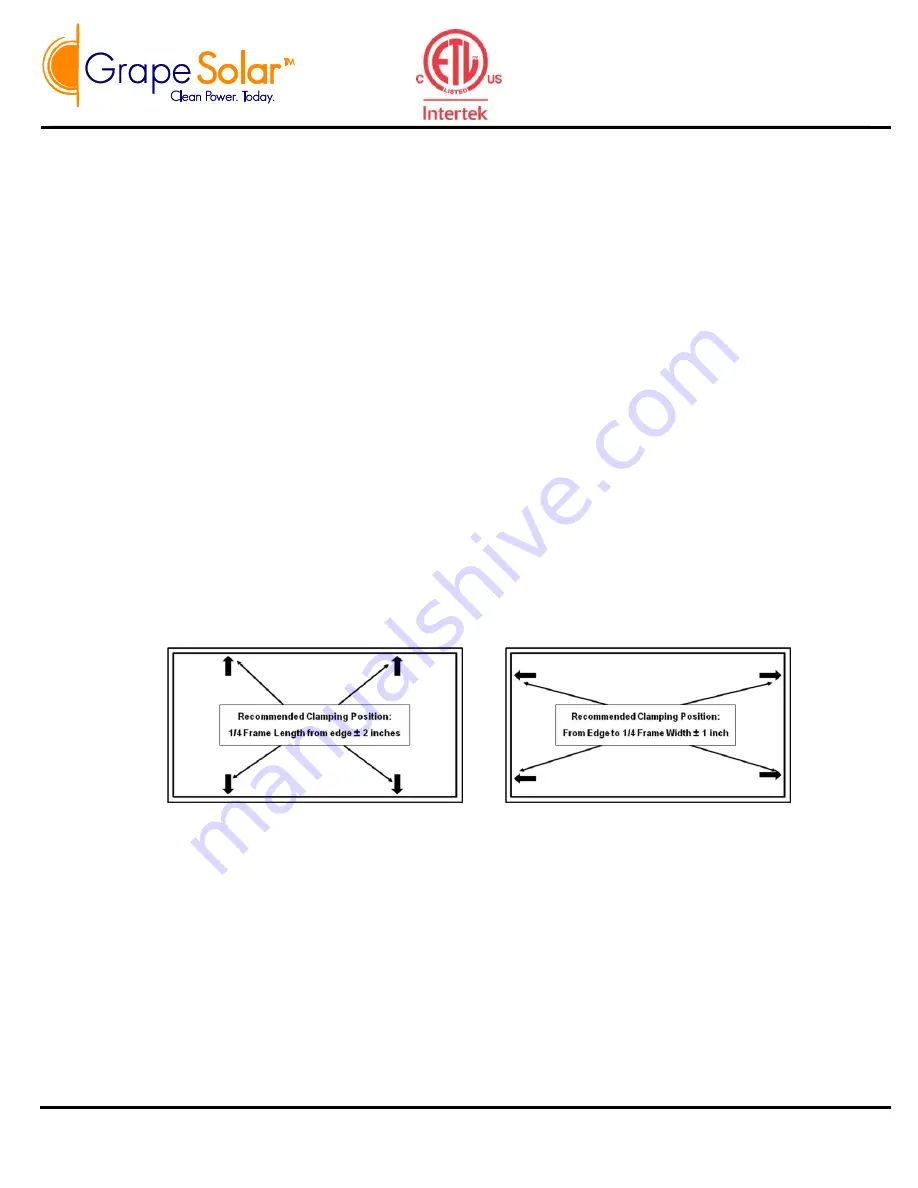

5.9.2

Pressure Clamps or Clips: Mount the module with the clamps or clips on the module frame.

Installers should ensure the clamps are of sufficient strength to allow for the maximum

design pressure of the module.

5.10

It is recommended that modules be securely fastened on the long side of the frames, but

mounting the module only on the short side is allowed. The maximum mechanical load applied

on the module

must

not

exceed 30 lbs/ft

2

(1600 Pascal).

IV.

MAINTENANCE

1.

No routine maintenance is required.

2.

Grape Solar recommends that periodic inspection of the PV system for tight electrical and mechanical

connection and free of corrosion should be performed.

3.

Periodic cleaning of modules is not required, but is recommended, as periodic cleaning can result in

better performance of the PV system, especially in regions with low levels of annual precipitation.