CE5000-UM-251-9370

1-2

1. INTRODUCTION

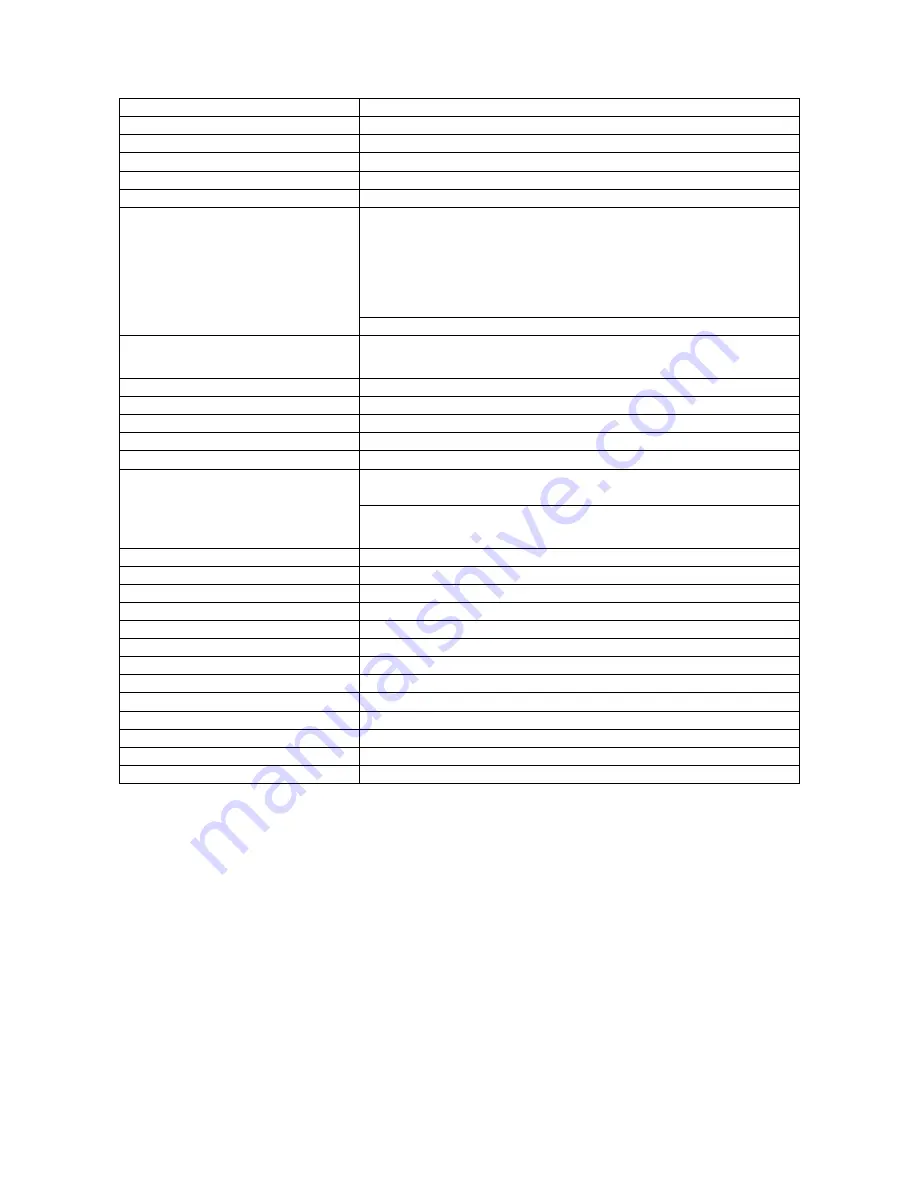

CE5000-120AP

Item

CE5000-120AP

CPU

32-bit CPU

Configuration

Grit rolling

Drive system

Digital servo

Maximum cutting area

1164 mm x 50 m

Maximum guaranteed cutting area

1164 mm x 3 m

*1

Compatible media widths

Media widths 160 to 270, 300 to 400, 440 to 540, 580 to 680, 710 to 810, 850 to

950, 990 to 1090, 1120 to 1220 mm (the effective drawing area is the

maximum obtainable area for the corresponding medium width) Up to

1180 mm when roll media (2-inch core) is used

Maximum roll outer diameter 190 mm

Media types

Fine quality paper for apparel patterns (64 to 130 g/m

2

)

Roll media diameter: 2-inch, 3-inch

Maximum cutting speed

60 cm/s

Specifiable cutting speeds

1 to 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60 cm/s

Cutting force

20 to 300 gf (31 levels)

Mechanical resolution

0.005 mm

Programmable resolution

GP-GL: 0.1/0.5/0.025/0.01 mm, HP-GL

TM *3

: 0.025 mm

Repeatability precision

Mechanical precision Within 0.1 mm/3m

*2

Guaranteed precision Within ±0.5 mm/3 m, up to a maximum of five consecutive pages

*1

(cutter pen/plotter pen exchange precision is also included)

No. of pens mountable

2

Compatible cutter blade type

Supersteel

Compatible pen type

Water-based fiber-tip pens, Oil-based ballpoint pen

Interfaces

RS-232C/USB 2.0 (Full speed)

Buffer capacity

2 MB

Command modes

GP-GL, HP-GL

TM *3

(selected on the control panel)

Display panel

LCD (16 characters x 1 row)

Rated power supply

100 to 240 V AC, 50/60 Hz

Power consumption

100 VA

Operating environment

10°C to 35°C, 35% to 75% RH

Conditions for guaranteed precision

16°C to 32°C, 35% to 70% RH

External dimensions (W x D x H)

Approx.

1,487 x 656 x 1189 mm

Weight

43 kg

*1: When the following Graphtec-specified conditions have been met:

• Graphtec-specified paper must be used for cutting/plotting.

• “PAPER LOAD: 2” must be specified for the PAPER LOAD setting and “UNTIL: 180 seconds” for the PAPER READY

TIME setting.

• After five pages have been cut/plotted consecutively, the paper must be reloaded.

• If expansion or contraction of the paper due to temperature and/or humidity changes has occurred during a cutting

or plotting operation, the following margins of error are added to the repeatability precision value:

0.1 mm/°C, 0.3 mm/10% RH.

*2: The precision specification is the precision that was obtained when Graphtec’s mylar film was used to measure the

mechanical precision. Please note that as only fine quality pattern paper can be used with this device, the precision

may differ slightly.

*3: HP-GL

TM

is a registered trademark of Hewlett-Packard Company.

Summary of Contents for CE5000-120

Page 1: ...CE5000 UM 251 09 9370 CE5000 Series SERVICE MANUAL MANUAL NO CE5000 UM 251 CUTTING PLOTTER...

Page 24: ......

Page 28: ...CE5000 UM 251 9370 3 4 3 OPERATIONS CE5000 120AP ENTER key ENTER key...

Page 34: ......

Page 36: ......

Page 72: ......

Page 90: ......

Page 96: ......

Page 100: ......

Page 116: ......