12-3

When It Does Not Work Right

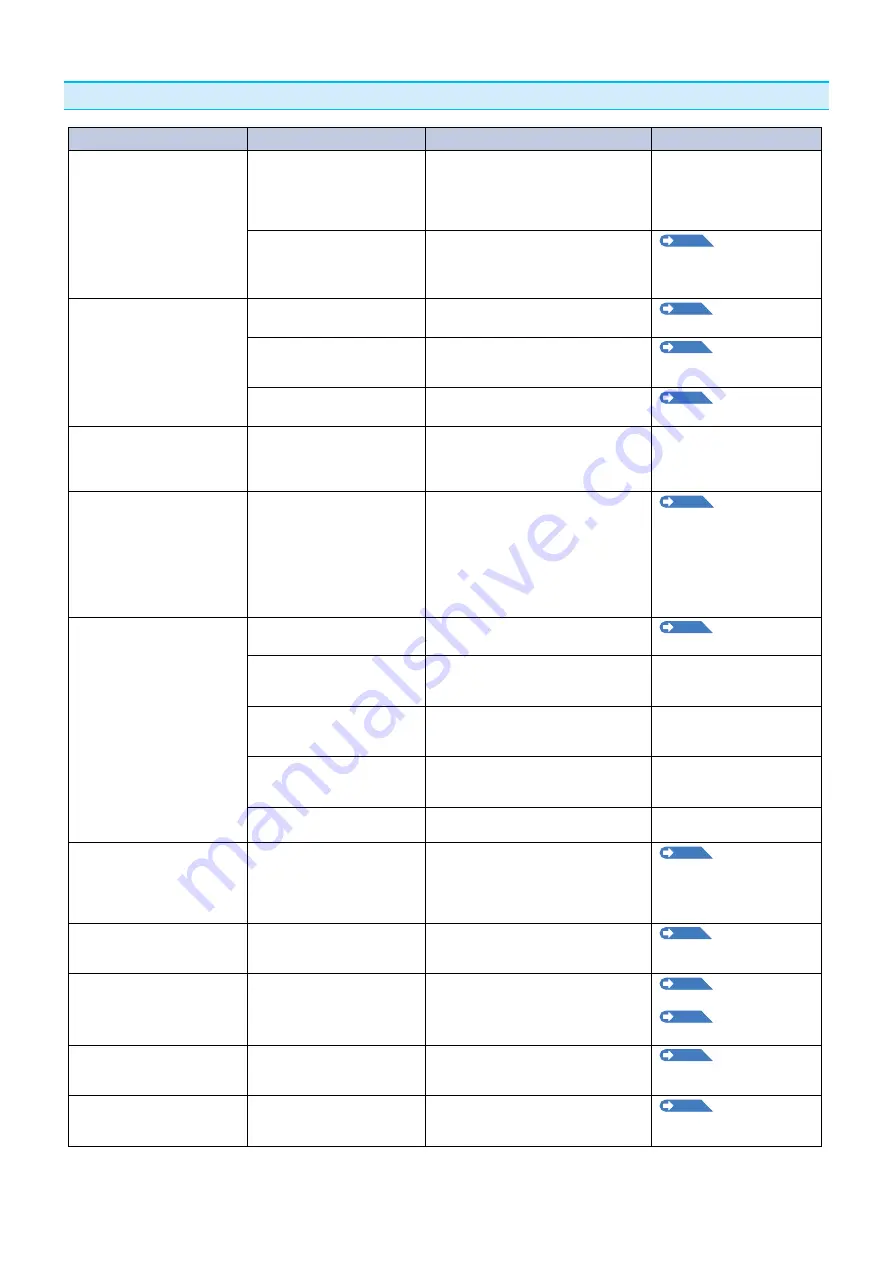

Symptom

Possible Cause

Solution

Reference

• Drops the meda whle

detectng.

Brght lght mght be shnng

onto the meda sensor.

Block the lght f there s drect sunlght

shnng on the plotter that s placed

near the wndow.

Move away the fluorescent lamps if

there s one close to the plotter.

Meda sensor may be

defectve.

Contact your sales representatve

or the Graphtec call center. Set the

meda sensor to DISABLED to use the

plotter temporarly.

P.9-4

Enablng/

Dsablng the Meda

Sensors (MEDIA SENSOR)

• Meda wobbles.

Push rollers are not set

correctly on the grt rollers.

Check the poston of the push rollers.

P.2-7

Loadng Meda

(Paper)

Changng of the hold-down

force of the push roller s not

sutable for the meda.

Please set a meda sutable for

changng the hold-down force.

P2-18

Changng the

Hold-down Force

Roll meda s not set properly.

Set the roll meda properly.

P.2-7

Loadng Meda

(Paper)

• One of the push roller goes

off the meda.

The leadng edge or the

tralng edge of the meda s

not cut straght aganst the

meda.

Cut the edge of the meda straght.

• A "Poston Error" appears

when the tool carrage hts

the left sde of the devce

after settng the meda and

choosng a meda type. Or

a "Poston Error" appears

when t hts the rght sde of

the devce.

Push roller sensor may be

defectve f t hts the left sde

of the plotter.

Home sensor may be

defectve f t hts the rght

sde of the plotter.

Contact your sales representatve or

the Graphtec call center. Set the push

roller sensor to DISABLED to use the

plotter temporarly.

P.9-5

Enablng/

Dsablng the Push Roller

Sensors (PUSH ROLLER

SENSOR)

• The plotter stops wth

"POSITION ALARM"

displayed during initialization

or cuttng.

CONDITION settng for the

meda s nvald.

Slow down the speed or lower the

FORCE.

P2-30

Settng the Tool

Condton

The pen carrage does not

move by httng somethng.

Move the object dsturbng the

operaton, and turn on the plotter after

turnng t off once.

External force s appled to

the pen carrage whle cuttng.

Move the object dsturbng the

operaton, and turn on the plotter after

turnng t off once.

Movement s dsturbed by the

meda chaff n the operaton

area.

Move the object dsturbng the

operaton, and turn on the plotter after

turnng t off once.

The plotter s defectve.

Contact your sales representatve or

the Graphtec call center.

• It s cuttng wth orgn pont

shftng to center of the

meda.

Data created wth lower left

orgn pont s receved when

the plotter s set wth center

orgn pont.

(Wth HP-GL command)

Reset the orgn pont to center on

the applcaton software, or reset the

orgn pont of the plotter to lower left.

P3-9

Settng Orgn

Pont When HP-GL s Set

• Meda jumps out to forward

sde.

Selected wrong type of the

meda.

Check the type of meda, "SHEET",

"ROLL-1 REAR SET", or "ROLL-2

REAR SET".

P2-26

Settng Feedng

Method

• Dsplays command error.

Data sent to the plotter s not

correct.

Check the data.

P12-6

Error Message n

GP-GL Command Mode

P12-7

Error Message n

HP-GL Command Mode

• It cannot cut above certan

length.

Length of the cut s exceedng

the length of the page set on

the plotter.

Press the [FAST] key and check the

cuttng area.

Match the settng for the page length.

P4-5

Settng Length of

the Page

• There are too many tool up

and down.

Settng for the tangental

mode s set to ON.

Turn OFF the settng for the tangental

mode unless you are cuttng thck

meda.

P6-3

Settng the

Tangental Mode