2-10

3

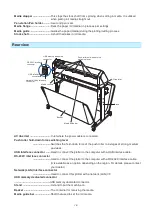

Set the stock shaft in from the front.

CAUTION

•

During a plotting or cutting operation, be sure

to keep your hands, hair, and so forth away

from the media stocker, gears and rollers.

•

When you are installing media, be careful for

gear, a roller, etc. not pinch you finger.

•

Deviations and errors may result if the stock

shaft is misaligned when plotting begins.

Align the receiving end of the media shaft with the grooves

on the roller and push down firmly to set it in place.

Stock shaft

Groove

Roller

Media stopper

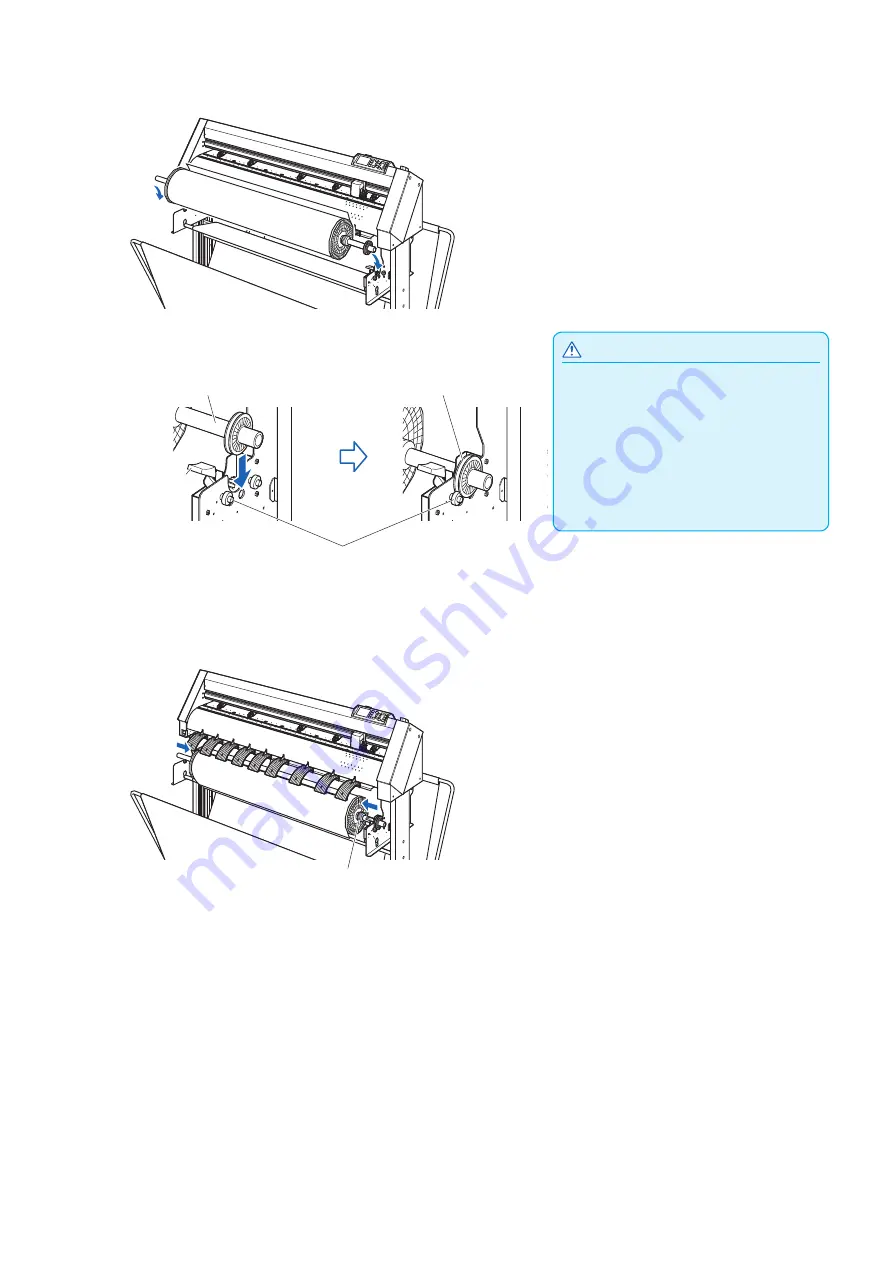

4

The left and right media flanges feed in the paper roll media.

Please tighten the flange screw and fasten the paper roll into

the desired position.

Flange screw

Summary of Contents for CE7000-130AP

Page 1: ...USER S MANUAL MANUAL NO CE70AP UM 151 CE7000 130AP CUTTING PLOTTER...

Page 2: ......

Page 19: ...1 3 Dedicated accessories A stand with a basket is supplied...

Page 84: ......

Page 104: ......

Page 110: ......

Page 128: ......

Page 184: ......

Page 245: ...A 7 PAUSE MENU 2 Continued MENU screen AXIS SETTING 1 1 Default screen Continued 1 2...

Page 246: ...A 8 3 PAUSE MENU Continued MENU screen AREA PARAMETERS 1 1 Default screen Continued 1 2 3 4...

Page 250: ...A 12 PAUSE MENU Continued MENU screen TEST 1 2 TEST 2 2 Default screen Continued 2 3 1 1 4...

Page 251: ...A 13 PAUSE MENU MENU screen MEM SETTING 1 1 1 Default screen Continued Default screen Finish...

Page 254: ......

Page 258: ......

Page 260: ......