5-11

7

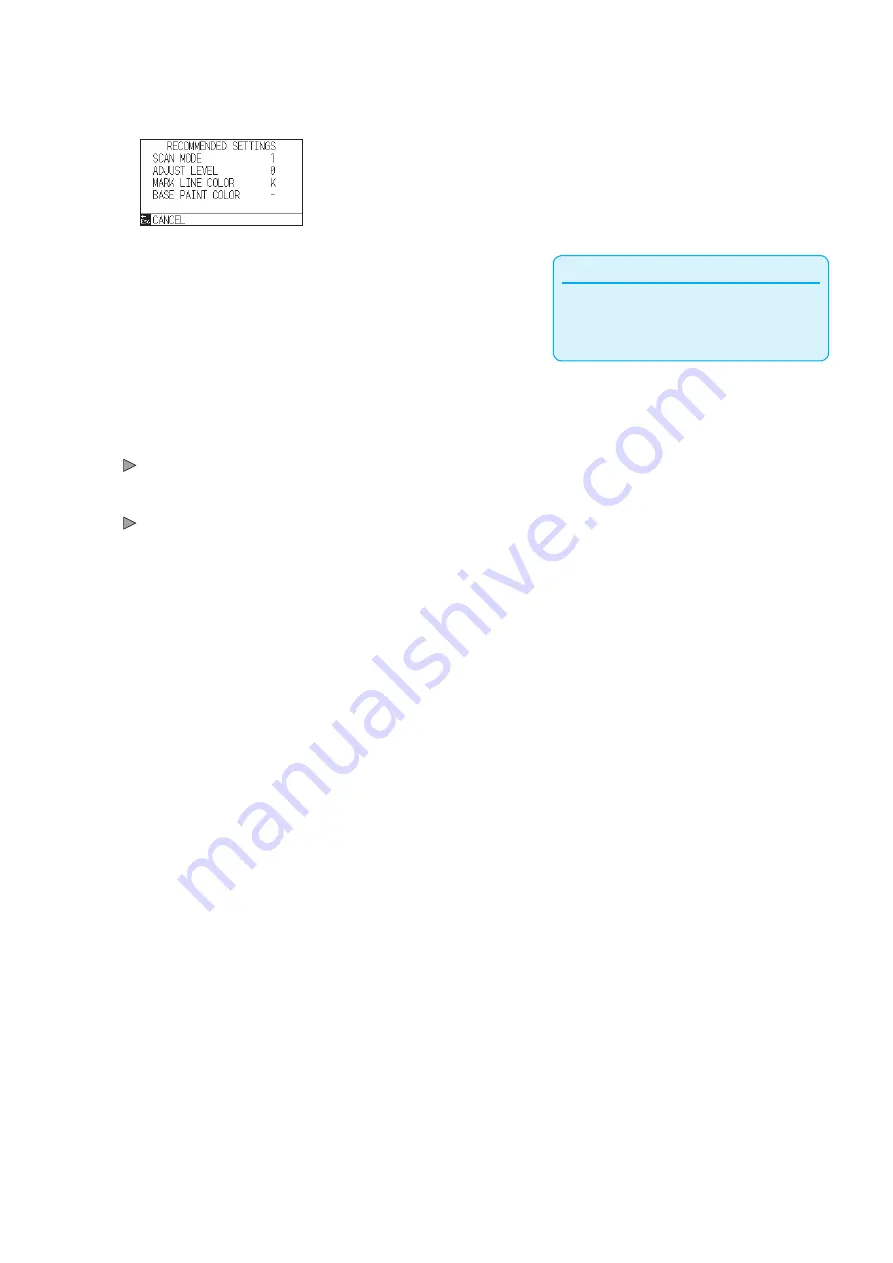

The appropriate registration mark color is calculated from the

detected media condition and the color is displayed.

Supplement

The display color of "MARK LINE COLOR" is Y:

yellow, M: magenta, C: cyan, K: black, W: white,

R: red, G: green or B: blue.

SCAN MODE: Recommended scanning mode 1/2/3 is

displayed.

ADJUST LEVEL: Recommended registration mark

adjustment value is displayed.

MARK LINE COLOR: Recommended color is displayed.

BASE PAINT COLOR: Recommended color is displayed.

8

Confirm the setting and press the [ESC] key (CANCEL).

It will return to ARMS SETTING screen (1/3).

9

Press the [PAUSE/MENU] key.

It will return to default screen.

Summary of Contents for CE7000 Series

Page 1: ...CE7000 SERIES CUTTING PLOTTER USER S MANUAL MANUAL NO CE7000 UM 151 ...

Page 2: ......

Page 18: ......

Page 104: ......

Page 118: ......

Page 168: ......

Page 220: ......

Page 232: ......

Page 254: ......

Page 290: ......

Page 328: ......

Page 343: ...A 15 PAUSE MENU Continued MENU screen TEST 1 2 TEST 2 2 Default screen Continued 2 3 1 1 4 ...

Page 348: ......

Page 352: ......

Page 354: ......