FC2240-UM-251-9370

1-2

1. INTRODUCTION

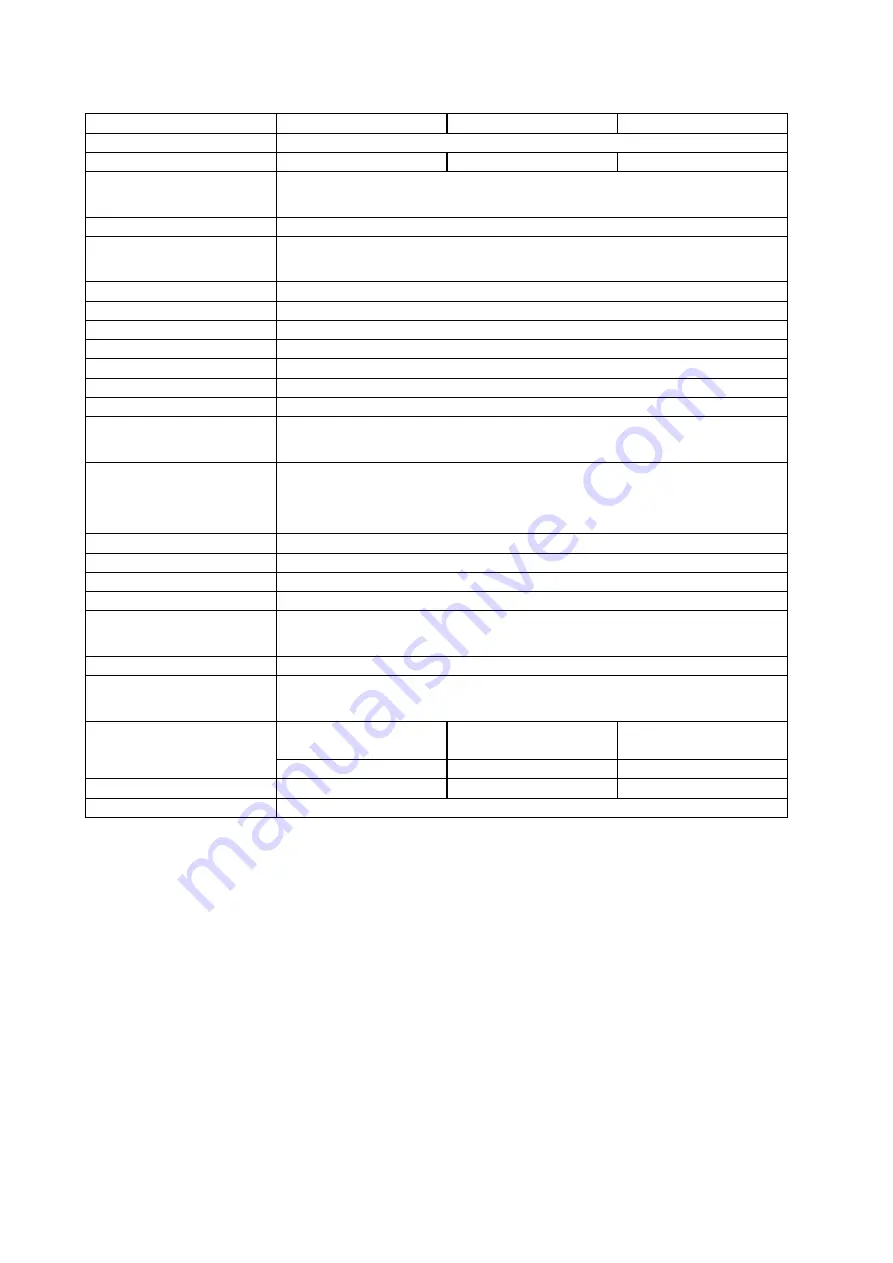

1.3 Main Specifications

FC2240-60VC

FC2240-120VC/MG/ES

FC2240-180VC/ES

Configuration

Flatbed

Effective cutting area

610 x 920 mm

1200 x 920 mm

1740 x 920 mm

Media hold-down method

VC models: Vacuum suction, MG models: Magnetic,

ES models: Electrostatic adhesion

Maximum cutting speed

400 mm/sec (40-step range)

Cutting force

High force mode: 9.8 N (1 kgf) max : 40-step range 2 to 80

Standard force mode: 4.9 N (500 gf) max : 40-step range 1 to 40

Minimum character size

About 10 mm square (varies with the character font and cutting media)

Mechanical resolution

0.0025 mm

Programmable resolution

GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL

TM

mode: 0.025 mm

Distance accuracy

Within 0.1% of the distance moved (plotter mode)

Perpendicularity

Within 0.5 mm/900 mm (plotter mode)

Repeatability

Within 0.1 mm (plotter mode)

Number of pens/cutters

2

Cutter and pen types

Cutter blades: Supersteel

Pens: water-based fibertip, oil-based ballpoint, disposable ink pen

*1

Cutting media

Marking film (vinyl, fluorescent, reflective), Stiff paper/card up to 0.5 mm

thick, Sandblast rubber sheets up to 1 mm thick, High-intensity reflective

film. Polystyrene foam sheets

Interfaces

RS-232C, Centronics, USB 2.0 (full speed); auto-switching

Buffer memory

2 MB

Command sets

GP-GL and HP-GL

TM

emulation

LCD panel

20 characters x 2 lines

Power supply

100-120 VAC, 50/60 Hz, 1.2 A max

220-240 VAC, 50/60 Hz, 0.7 A max

Operating environment

10 to 35˚C, 35 to 75% RH (non-condensing)

Guaranteed precision

operating environment

16 to +32˚C, 35% to 70% RH (non-condensing)

External dimensions

(H x W x D) Horizontal 857 x 920 x 1285 mm

944 x 1568 x 1285 mm 944 x 2068 x 1285 mm

Tilted

----

*2

1687 x 1568 x 987 mm

1687 x 2068 x 987 mm

Weight (including stand)

Approx. 58 kg

Approx. 69 kg

Approx. 74 kg

Option

Vacuum pump (Blower) [VC models only]

*1: Disposable ink pens cannot be used with the high-force pen (Pen 2 holder).

*2: The writing panel on VC models cannot be tilted.

Summary of Contents for FC2240

Page 1: ...CUTTING MACHINE SERVICE MANUAL FC2240 FC2240 UM 251 04 9370...

Page 2: ......

Page 8: ...FC2240 UM 251 9370 vi...

Page 38: ...FC2240 UM 251 9730 3 15 3 OPERATIONS Sample printout by the CONDITION function...

Page 42: ...FC2240 UM 251 9730 4 2 4 DAILY MAINTENANCE AND STORAGE...

Page 70: ...FC2240 UM 251 9370 7 26 7 DISASSEMBLY AND ADJUSTMENT...