FC2240-UM-251-9370

7-12

7. DISASSEMBLY AND ADJUSTMENT

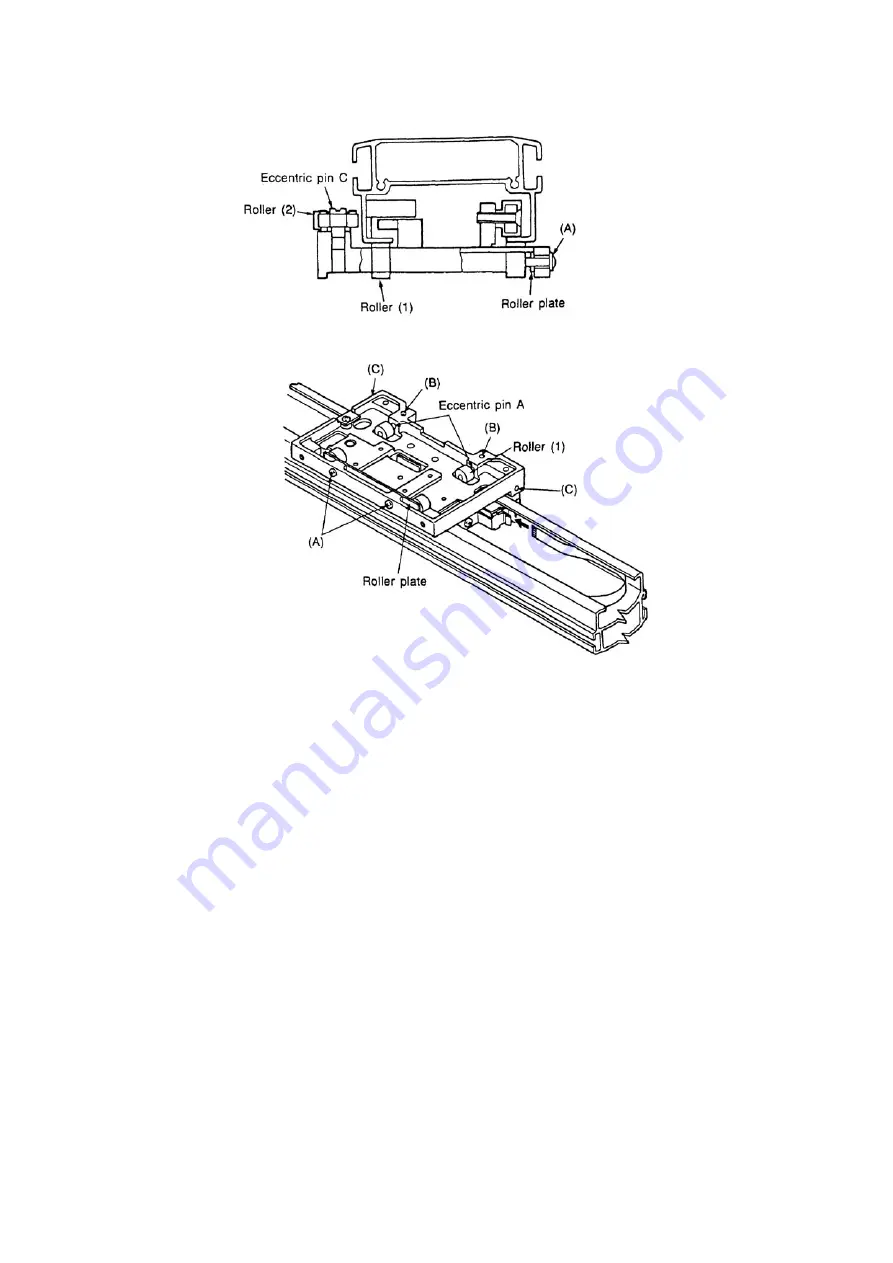

7.6 Adjusting the Roller Pressure of the Y Slider

(1) Mounting the Y slider onto the Y bar

• Loosen the two screws (A), lower the roller plate and temporarily secure it in that position.

• Loosen the setscrews (B) at the two eccentric pins A, then temporarily secure the roller (1) in a

lowered position.

• Loosen the set-screws (C) at the two eccentric pins C, then move roller (2) outside of the Y slider and

temporarily secure it in that position.

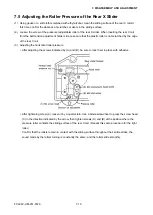

(2) Adjusting the Y slider’s roller pressure

• With the Y slider oriented as shown in the figure above, insert it onto the Y bar, then move each roller

back into contact with the sliding surface by performing the steps in (1) above in reverse sequence.

• Visually confirm that each roller rotates while maintaining contact with the sliding surface. Check that

there is no play in the front, back, or side directions.

• Make sure there are no discrepancies in the “grating” load of the rollers.

• The sliding load shall be 30 gf ± 5.

• After the adjustment is completed, apply adhesive to the four set-screws.

Summary of Contents for FC2240

Page 1: ...CUTTING MACHINE SERVICE MANUAL FC2240 FC2240 UM 251 04 9370...

Page 2: ......

Page 8: ...FC2240 UM 251 9370 vi...

Page 38: ...FC2240 UM 251 9730 3 15 3 OPERATIONS Sample printout by the CONDITION function...

Page 42: ...FC2240 UM 251 9730 4 2 4 DAILY MAINTENANCE AND STORAGE...

Page 70: ...FC2240 UM 251 9370 7 26 7 DISASSEMBLY AND ADJUSTMENT...