6-4

When Cut Results Are Poor

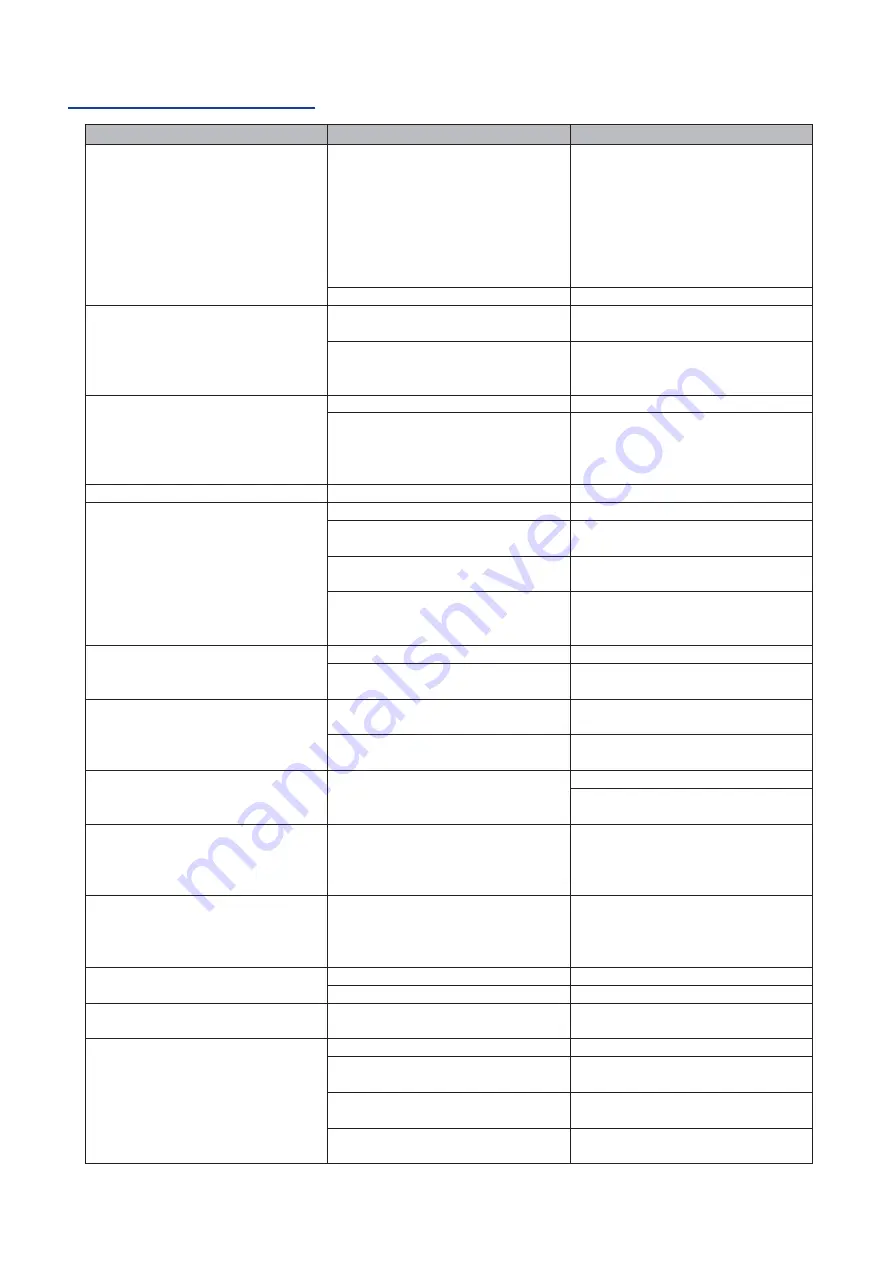

Symptom

Cause

Solution

The cut corners are rounded or too

pointed.

The OFFSET is incompatible with the

cutter blade being used.

Adjust the OFFSET value of CUT

CONDITION.

Match the setting to the blade being

used.

> If it is too low, the corners become

rounded.

> If it is too high, the corners are too

pointed.

There is abrasion of the blade.

Replace the cut blade.

The cut line starts out crooked.

The cutter blade does not rotate

smoothly.

Remove any foreign matter inside the

holder.

The Offset Cut Pressure is too low.

Raise the Offset Pressure setting.

(The Offset Pressure is separate from

the cutting FORCE)

The blade skips and does not

completely cut lines that should be

solid.

Solid lines are not cut at a constant

depth. (Slight skipping of the blade)

The cutter blade is extended too far.

Adjust the blade length.

The cutting SPEED is too high.

Reduce the SPEED setting value of

CUT CONDITION.

Coarse resolution of curved lines.

The output data resolution is too low.

Increase the output data resolution.

The cutting medium curls up at the

corners.

The cutter blade is extended too far.

Adjust the blade length.

The OFFSET is incompatible with the

cutter blade being used.

Change the OFFSET setting value of

CUT CONDITION.

The cutting SPEED is too high.

Reduce the SPEED setting value of

CUT CONDITION.

The blade is dull.

Adjust the blade length.

Or, replace the cutter blade with the

new one.

The cutter blade is cutting into the

backing sheet.

The cutter blade is extended too far.

Adjust the blade length.

The cutting FORCE is too high.

Reduce the FORCE setting value of

CUT CONDITION.

The cutter blade has fallen out of the

cutter plunger.

The cutter blade is the incorrect

diameter for the plunger.

Use a cutter blade that matches the

plunger's diameter.

The spring of the cutter blade

(CB09UA) has fallen out.

Replace the cutter blade with a new

RQHÀWWHGZLWKDVSULQJ

The medium can be cut but is hard to

weed afterward.

The medium gets entangled during

cutting.

Reduce the blade length.

Reduce the FORCE setting value of

CUT CONDITION.

Abnormal noise generated by the

cutter plunger during cutting.

The medium is discolored where the

cutter blade has passed.

The medium is stuck in the tip of the

plunger.

Adjust the blade length and the

FORCE of CUT CONDITION.

The setting value of CUT CONDITION

cannot be maintained.

The setting value of CUT CONDITION

cannot be changed.

7KH>(17(5@NH\ZDVQRWSUHVVHG

after a setting was changed.

Make sure you are setting the

conditions correctly.

Media is bowed.

The media is set at a slant.

Correct the setting of the media.

7KHPHGLDÁDQJHLVQRWVHWSURSHUO\

5HVHWWKHPHGLDÁDQJHSURSHUO\

7KHVSHFLÀHGOHQJWKLVQRWSORWWHGRU

cut. (slight distance error)

The distance adjustment value is not

appropriate.

Specify the appropriate distance

adjustment value.

The starting and end points do not

match.

The data is not connected.

Verify the data in the application.

The backing sheet is too soft.

Change to media with a hard backing

sheet.

Cutter blade rotation is not smooth.

Verify that refuse, etc. is not stuck on

the blade.

The life of the cutter plunger.

Replace the cutter plunger with new

one.