EN - 27

Check Hydraulic Fluid Level

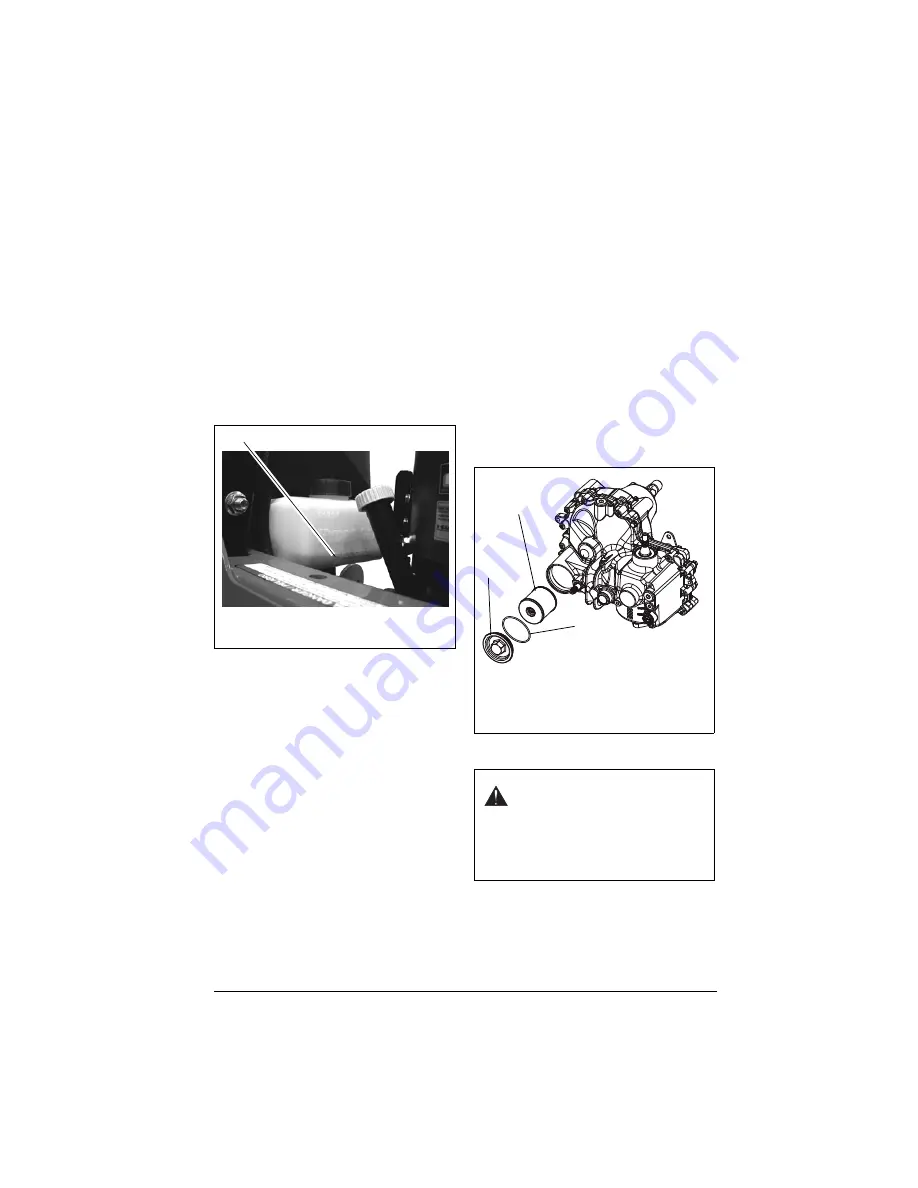

(Figure 10)

Check the system with the unit cold and

parked on a flat, level surface.

Then run the unit for about one minute and

recheck the levels.

Add Hydraulic Fluid

1. Remove the cap from the expansion

tank.

2. Fill the expansion tank with 15W-50

synthetic motor oil (Gravely p/n

00057100) or equivalent until oil level

reaches the cold fill line on the tank.

3. Install the expansion tank cap and then

purge the system. See

Change Hydraulic Fluid and Filter

NOTICE:

Change hydraulic fluid and filter

after the first 75 hours of operation and then

every 400 hours. Use 15W-50 synthetic

motor oil (Gravely p/n 00057100) or

equivalent.

1. Run the unit for a few minutes to warm

the hydraulic fluid, and then shut off the

engine, remove ignition key, and wait for

all moving parts to stop before servicing

unit.

2. Place container under oil filter to catch

oil.

3. Remove the filter cover from the

transaxle. Remove and discard the

o-ring from the cover.

4. Remove the bottom oil fill vent port plug

from the transaxle to drain completely.

5. After the oil has drained from the unit,

replace the bottom oil fill vent port plug

and then remove the oil filter.

6. Clean the filter mounting surface and

then lubricate rubber gasket on new oil

filter with clean hydraulic oil.

7. Spin new oil filter onto filter housing until

it makes contact. Tighten oil filter

another 3/4 turn.

8. Install the filter cover removed in step 3.

Tighten the mounting screws to 40 –

45 lbf-ft (54 – 61 N•m).

9. Remove the top fill vent port plug and fill

with 15W-50 synthetic motor oil (Gravely

p/n 00057100) or equivalent until oil

appears at the bottom of the drain plug

(151 ounces (4475 mL) per transaxle).

Install the drain plug and tighten to 16.7

lbf-ft (22.5 N•m).

10. Follow the instructions in

11. Repeat steps 2 – 10 for the other

transaxle.

Purging the Hydraulic System

NOTICE:

Purge the system of air any time

the transaxle has been opened for

maintenance or when oil has been added to

the system.

Figure 10

1. Cold Fill Indicator Mark

WARNING:

This adjustment

requires operating the engine.

Use extreme care to avoid

contact with moving parts and hot

surfaces. Be sure rear of unit is

well supported and secure before

starting engine.

Figure 11

1. Oil Filter

2. Filter Cover/Drain Plug

3. O-Ring