GB - 18

HYDRAULIC FLUID

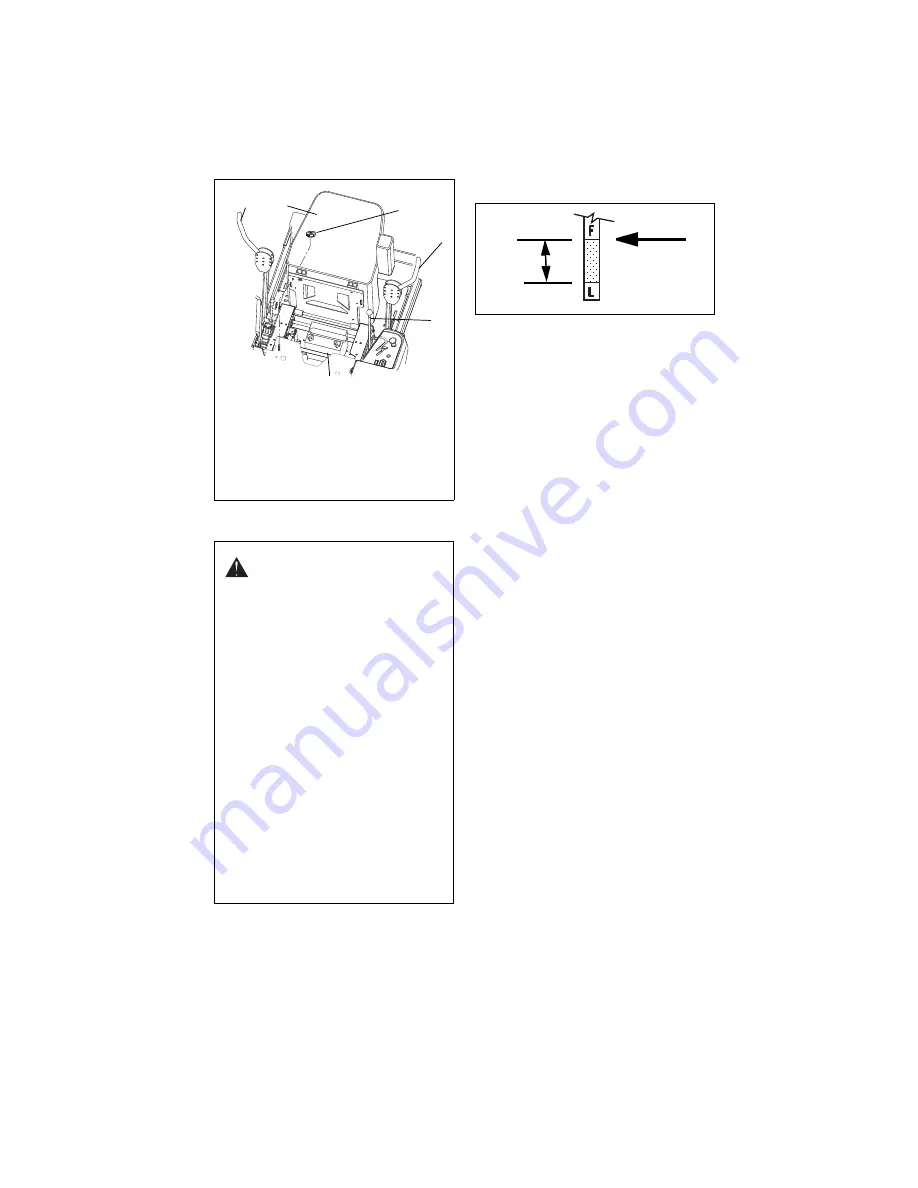

Check Hydraulic Fluid Level

1. Start the unit and run it to operating

temperature (about 10 minutes).

2. Cycle the control levers forward and

backward two or three times.

3. For units equipped with a hydraulic deck

lift, raise and lower the deck completely

two or three times.

4. Shut OFF engine. Engage parking

brake. Remove the ignition key.

5. Put seat in service position. See

6. Remove any dirt that may be around the

cap/dipstick on the hydraulic reservoir.

7. Remove cap/dipstick.

8. Check hydraulic oil level mark on

cap/dipstick.

9. Add Mobil 1 Extended Performance

15W50 or equivalent as needed

(Gravely p/n 00057100). Do not overfill.

Change Hydraulic Fluid and Filter

NOTE: Change the hydraulic oil filter and

hydraulic oil every 400 hours. Use Mobil 1

Extended Performance 15W50 Synthetic Oil

or equivalent for best component life (Gravely

p/n 00057100).

NOTE: When changing the oil, only about 1.5

quarts (1.4 liters) will drain. The rest of the oil

will remain in the pumps and motors.

1. Clean around dipstick cap and dipstick.

Remove dipstick.

2. Place container under oil filter to catch

oil.

3. Remove oil filter.

4. Allow tank to drain.

5. Lubricate rubber gasket on new oil filter

with clean hydraulic oil.

6. Spin new oil filter onto filter housing until

it makes contact. Tighten oil filter

another 1/2 turn.

7. Add new oil to the oil tank. It will take

about 1.5 quarts (1.4 liters). Use Mobil 1

Extended Performance 15W50

Synthetic Oil or equivalent for best

component life (Gravely p/n 00057100).

8. Check hydraulic oil level mark on

cap/dipstick.

9. Properly dispose of waste oil.

WARNING: HYDRAULIC FLUID

can result in severe burns. Fluid

in hydraulic system can penetrate

skin and result in serious injury or

death.

Be sure to stop the engine before

doing any work on hydraulic

parts.

Keep body and hands away from

pin holes or nozzles which expel

hydraulic fluid when under

pressure. Use paper or

cardboard, not hands, to search

for leaks.

Ensure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to system.

FOREIGN FLUID INJECTED

INTO BODY can result in

gangrene. Fluid must be

surgically removed within a few

hours by a doctor familiar with

this form of injury.

1. Service

Position

2. Seat Knob

3. Steering

Levers

4. Parking

Brake

5. Battery

Figure 6

OF3361

FULL Mark

Operating

Range

OE0380

Summary of Contents for Promaster 144

Page 35: ......