GB-18

2. Remove the spacer, handle, and eccentric spacer from the

steering lever.

NOTE: Position the right and left handles at the same height

position.

3. Install the spacer, handle, and eccentric spacer in the

appropriate height position. Do not tighten the nut holding

the eccentric spacer.

4. Turn the eccentric spacer until the right and left handles are

the same height. Tighten nut.

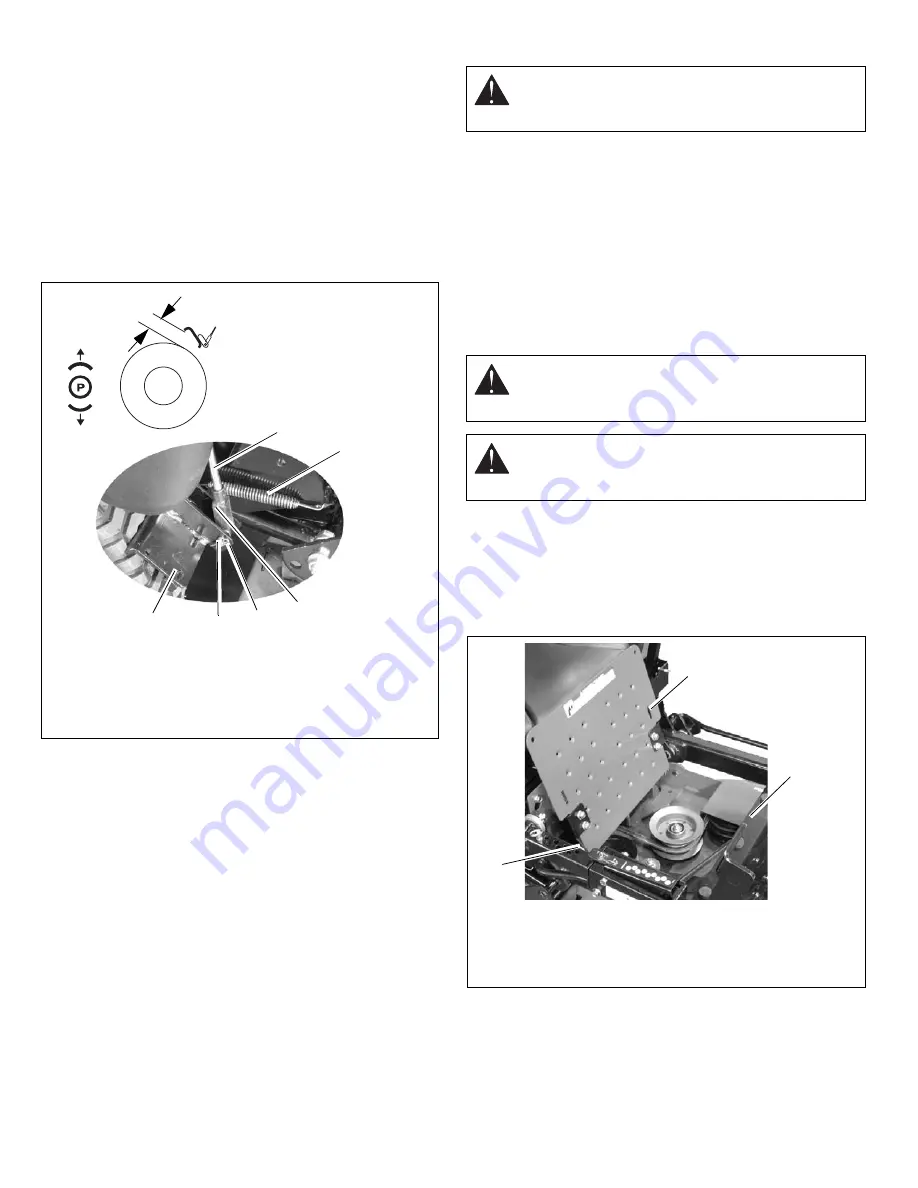

ADJUSTING THE PARKING BRAKE

The parking brake might need adjustment over time and after

new brake paddles have been installed.

Check Adjustment

NOTE: Be sure to check the parking brake on both sides of the

unit (Figure 14).

1. Disengage parking brake.

2. Measure the distance between the bottom edge of the

brake paddle and the tire.

There should be 3/8 in. - 1/2 in. (9.5 - 15.9 mm) between

brake paddle and tire.

3. Tires - Adjust tire pressure for front tires; 20-25 PSI

(138-172 kPa), rear tires; (992056, 314) 12-15 PSI (83-103

kPa), (992065) 15-18 PSI (103-124 kPa).

Adjust the Parking Brake

1. Disengage the parking brake.

2. Disconnect return springs from frame.

3. Disconnect clevis from parking brake paddle.

4. Turn clevis up the brake rod to decrease distance or down

the brake rod to increase the distance between the brake

paddle and the tire.

5. Replace clevis on parking brake paddle.

6. Replace return springs.

7. Check adjustment and repeat as needed.

PTO BELT

PTO Belt Access

1. Properly stop and park unit (See Operation on page 10).

2. Lower the mower.

3. Place seat in most rearward position.

4. Remove belt covers.

5. Place foot board in open position (Figure 15).

1. Parking Brake

Paddle

2. Brake Rod

3. Clevis

4. Return Springs

5. Hair Pin

6. Clevis Pin

Figure 14

OF3303

3/8 in. - 1/2 in.

(9.5 - 15.9 mm)

1

2

3

4

5

6

CAUTION: Use care when releasing spring tension.

Keep body parts well away from springs when

performing this operation.

WARNING: MOVING PARTS can cut or amputate

body parts. ALWAYS wait for moving parts to stop

before performing maintenance or service.

CAUTION: DAMAGED OR WORN BELTS may result

in injury and/or damage to unit. Check belts for

excessive wear or cracks often.

3

1. Footboard in

open position

2. Support Frame

3. Pivot

Figure 15

1

2

Summary of Contents for Promaster 34Z

Page 24: ...GB 24 ...