795-93851

10 of 49

12/15/21

MAINTENANCE

Cleaning

Your Clean-O-Matic is equipped with a filter (FIGURE 1 (L)) with a reusable screen collector element.

This screen collector should be cleaned at least once a week, more often in heavy use, in order to help

extend the life of the cleaning fluid and increase cleaning efficiency. Periodically, an oil filter cartridge

(see spare parts list below) can be placed in the filter canister in place of the screen collector. Running

the pump for a few hours will pull more contaminants out of the fluid and help extend fluid’s usable life.

Since an oil filter cartridge will clog within a short time, use for only one or two hours at the most.

Removing as much excess dirt, chips, and other contaminants as possible before cleaning dirty parts

will extend the life of the cleaning fluid. Another way to extend fluid life is to use Graymills Solvent

Savers. Contact Customer Service for further details.

Changing Fluid

•

Remove the flexible hose from the "L" support bracket, aim it over the tank sides into a proper

container and remove all but the last 1” of solvent using the pump.

•

Remove drain plug to drain remaining fluid.

•

Remove and clean the optional sludge trays. Wash the 40-mesh screen solvent filter and replace

the gasket if necessary. Wipe out the bottom of the tank to remove any accumulated sludge and

debris still remaining.

•

Replace the drain plug and optional sludge trays. Reassemble the filter. Refill the tank with fresh

cleaning fluid. Resume cleaning operations, checking for leaks at the drain plug and filter.

•

Always dispose of used cleaning fluid properly. Refer to the cleaning chemical SDS (safety data

sheet) and manufacturer's package label for instructions.

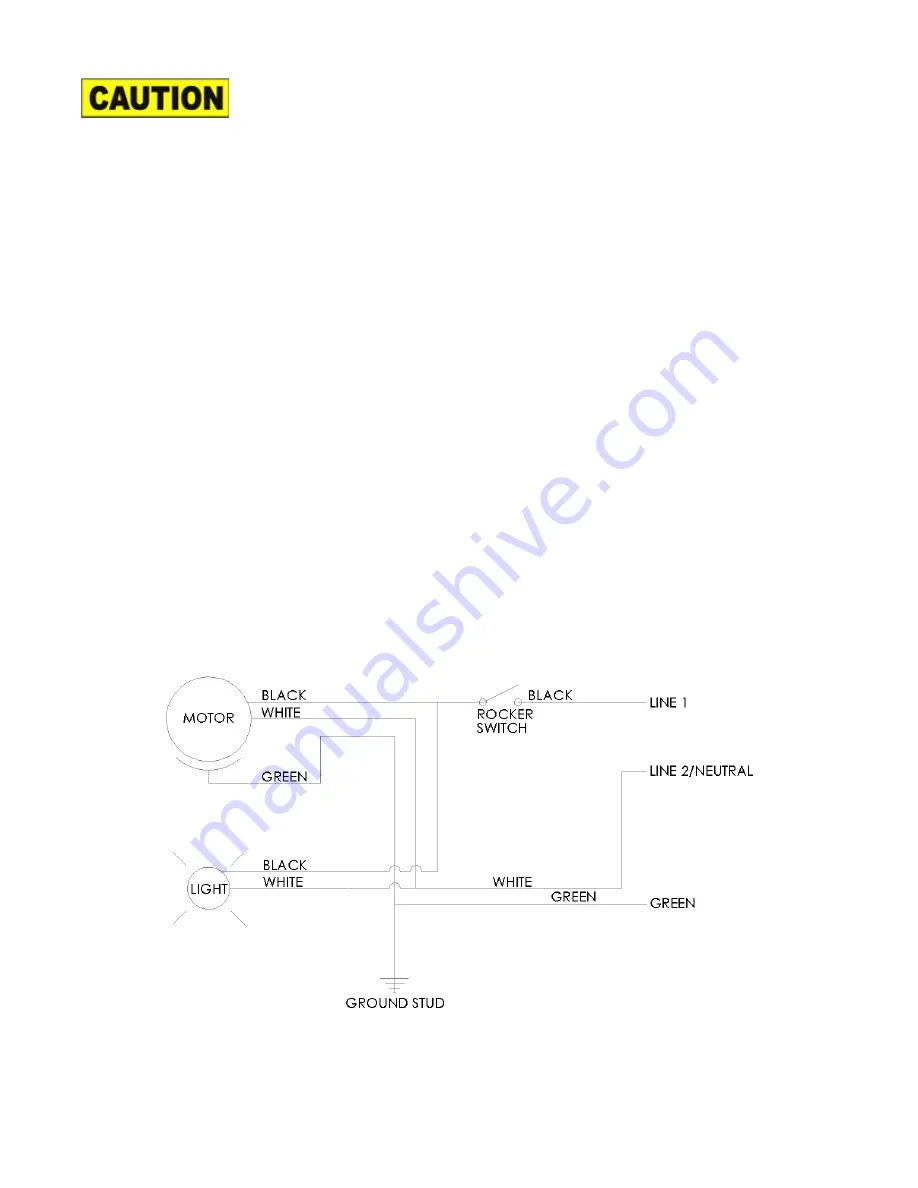

Wiring Schematic