Section 2: Operating Instructions

NTS2507, NTS2509, & NTS2511 s/n+ 2019+ NTS Seeder 313-900M

7/1/19

26

Level Seeder With Pull Hitch

1.

Transport to the field with seeder attached. For

detailed instructions, see

2.

Park seeder on level ground, raise seeder fully up,

place tractor in park or set park brake, shut tractor off,

and remove switch key before dismounting.

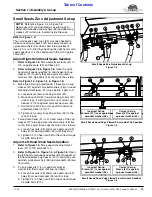

Refer to Figure 2-8:

3.

Remove wire retaining pins (#10), transport

locks (#11), and stroke control spacers (#9) from all

three hydraulic lift cylinders and store on nearby

storage racks as shown. Secure transport locks to

storage racks with wire retaining pins (#10).

4.

Start tractor and lower seeder to the ground using

factory float. Keep tractor hydraulic lever in factory

float while seeding seeds.

5.

Pull ahead 15 feet or until both front and rear rollers

are fully engaged in the ground and then stop.

6.

Without changing height of implement, shut tractor

down properly before dismounting. Refer to

Refer to Figure 2-8:

7.

Place a level (#19) on the mainframe from front to

back to verify frame is level (parallel) with the ground.

8.

If frame is not parallel with the ground, unhook tractor

from seeder as follows:

a. Attach park jack (#14) to jack mount (#16) with

detent pin (#13). Insert detent pin horizontally as

shown. Make sure detent pin is fully inserted.

b. Extend jack (#14) to remove load from drawbar.

IMPORTANT:

Front angling spike rollers will not

function properly unless frame is level to the ground.

IMPORTANT:

Always operate seeder with transport

wheels on the ground and seeder level to prevent

dirt build-up and seeder damage.

c. Leave hydraulic hoses (not shown) hooked to the

tractor unless they are too short to move the

tractor forward 6" with seeder unhooked from the

tractor. If needed, unhook hydraulic hoses as

follows:

•

Move hydraulic control lever back and forth

several times to release all hydraulic pressure.

•

Disconnect hoses from tractor duplex outlet and

store loose ends on the seeder frame to keep

dirt off the couplers.

d. Unhook safety chain (#12) from tractor.

e. Unhook seeder from tractor by removing hitch pin

keeper (#5), hitch pin (#6), and flat washers (#1A

& #1B). Be careful not to lose washers, hitch pin,

and hitch pin keeper.

f. Start tractor and drive forward until drawbar (#1) is

removed from clevis (#2). If attached, be careful

not to pull hydraulic hoses tight.

g. Shut tractor down properly before dismounting.

9.

Adjust park jack (#14) up or down until seeder main

frame is level (parallel) with the ground.

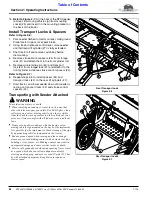

10. Check clevis hitch (#2). The clevis plates should be

in line with the drawbar. If not, then readjust clevis

hitch height up or down as follows:

a. Remove nylock nut (#17) and bolt (#18).

b. Move clevis (#2) until clevises upper and lower

plates are parallel with tractor drawbar.

c. Attach clevis (#2) to seeder hitch (#4) with existing

1"-8 x 6" GR5 bolt (#18) and nylock nut (#17).

Draw nylock nut up snug. Do not tighten.

d. To protect wire retaining pin (#7) from being bent,

move pin to the hole furtherest from the clevis or

store pin with the tractor until unhooking the unit.

IMPORTANT:

Clevis (#2) should be in line with

tractor drawbar during field operation to reduce wear

on the drawbar.

Align Clevis With Tractor Drawbar

Figure 2-8

39057