Section 6: Native Seed Rate Adjustment

NTS2507, NTS2509, & NTS2511 s/n+ 2019+ NTS Seeder 313-900M

7/1/19

52

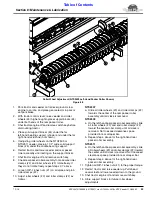

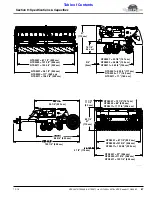

Native Seed High/Low Range Set-up

The native seed drive is associated with low range

sprocket only. If speed change sprocket is set for high

range operation, rearrange sprocket so that the 19 tooth

sprocket is located behind the 35 tooth sprocket. For

detailed instructions, Refer to

Native Seed Rate Adjustment

The setting should be

INCREASED

f or lighter than

average seed and

DECREASED

for heavier than

average seed.

1.

Raise the seeder and support it in a safe manner so

that the drive roller assembly will rotate freely.

2.

Partition off the outer end of the box so that seed can

be placed only over three discharge openings.

Drive Sprocket Location & Storage Placement

Figure 6-1

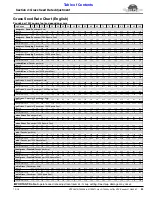

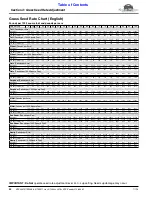

Refer to Figure 6-1 and Native Seed Rate Chart on

page 53:

3.

To adjust seed rate, first find the desired pounds/acre

or kilograms per hectare using the

on page 53. Determine which drive

sprocket (#1, #2, #3, #4, or #5) and gearbox drive

number setting (#5) are required. If needed, change

drive sprocket (#4) and drive number setting (#5):

a. Loosen chain idler nut (#8) and remove drive

chain (#9) from drive sprocket (#4).

b. Remove linchpin (#10) and drive sprocket (#4). If

a linchpin is not provided, loosen two set screws

on drive sprocket (#4) and remove drive sprocket.

c. Replace drive sprocket (#4) with the selected

drive sprocket (#1, #2, or #3).

d. Secure drive sprocket (#4) with linchpin (#10). If

linchpin is not provided, tighten the two set screws

on the drive sprocket.

e. Reinstall drive chain (#9) and adjust chain take-up

(#11). See

“Native Grass Seed Gearbox Drive

on page 56 for detailed instructions.

39028

f. Set gearbox drive lever (#7) to the selected drive

number (#5) by pulling up on lock pin (#6) and

adjusting lever to the correct number.

g. Release lock pin (#6). Make sure lock pin is fully

down and lever (#7) is locked from movement.

h. Place removed sprocket (#4) on the sprocket

storage holder (#12). Secure all four unused

sprockets on the holder with linchpin (#12).

4.

Refer to

on page 30: Engage native

seeds with lock in/out pin (#2). If applicable,

disengage small seeds with lock in/out pin (#5) and

grass seeds with lock in/out pin (#3 or #4).

5.

Rotate drive roller assembly to verify that the drive

system is working properly and that the discharge

openings are free from foreign matter.

6.

Place a container under the three discharge

openings to gather all the seeds as they are metered.

7.

Rotate rear roller the number of rotations noted in the

table above. Check the three cups to make sure each

cup has plenty of seed coming into it.

a. Weigh the seed which has been metered out and

divide that weight by three to get the number of

pounds or kilograms per seed cup.

b. Next, multiply number of pounds or kilograms per

seed cup by the number of seed cups on the

native seedbox to arrive at weight “A”.

c. If Weight “A” is calculated based on:

1/10 acre, then “A” x 10 = lbs/acre

1000 sq ft, then “A” x 43.56 = lbs/acre

1/20 hectare, then “A” x 20 = kgs/hectare

100 sq meters, then “A” x 100 = kgs/hectare

d. If calculated grass seed rate is different than the

suggested settings in the chart, then change

gearbox drive number and/or drive sprocket

accordingly.

8.

You may want to repeat calibration procedure if the

results of your calibration vary greatly from the

suggested settings in the chart.

Model

No

No. of Rear Roller Rotations to Cover

1/10

Acre

1000 Sq.

Ft.

1/20

Hectare

100

Sq. M

NTS2507

255

57

315

61

NTS2509

211 48

260

52

NTS2511

162 37

200

40

NOTE:

If total weight for 3 seed cups is in

ounces, divide that weight by 48 instead of 3.

Section 6: Native Seed Rate Adjustment