Section 8: Maintenance & Lubrication

NTS2507, NTS2509, & NTS2511 s/n+ 2019+ NTS Seeder 313-900M

7/1/19

58

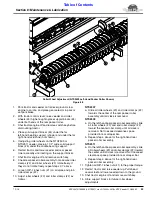

Native Seed Roller Chains

Figure 8-7

Native Seed Roller Chains

Refer to Figure 8-7:

Item Part No.

Description

1

809-115C

CHAIN RL #40 X 60 PITCH W/CON

2

809-309C

CHAIN RL #40 X 54 PITCH W/CON

3

809-133C

CHAIN RL #40 X 62 PITCH W/CON

4

809-037C

CHAIN RL #40 X 58 PITCH W/CON

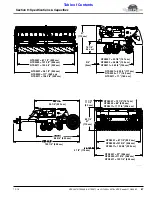

Grass Seeds Standard Roller Cain

Figure 8-8

Grass Seed Standard Roller Chain

Refer to Figure 8-9:

Item Part No.

Description

1

809-308C

CHAIN RL #40 X 56 PITCH W/CON

39032

72249

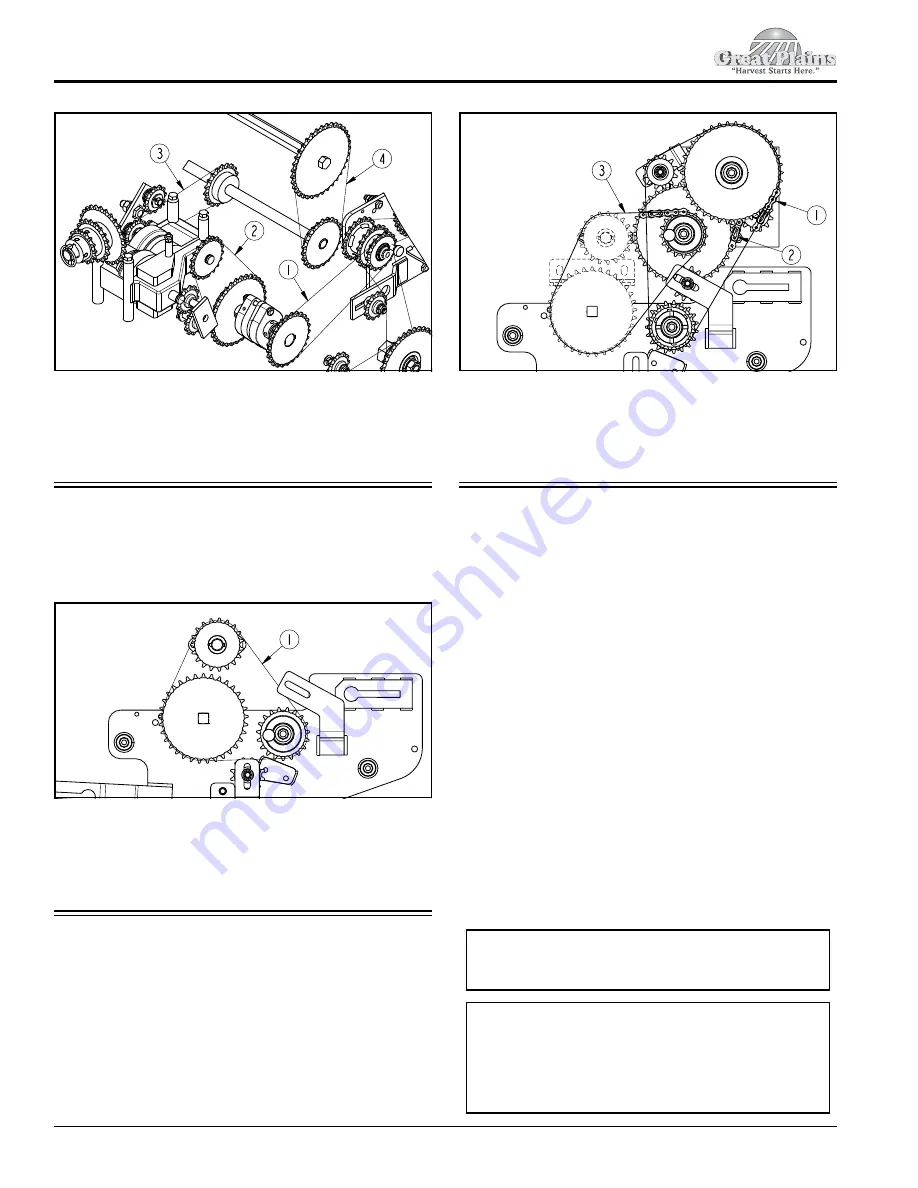

Grass Seed Reduction Roller Chains

Figure 8-9

Grass Seed Reduction Roller Chains

Refer to Figure 8-9:

Item Part No.

Description

1

809-094C

CHAIN RL #40 X 72 PITCH W/CON

2

809-253C

CHAIN RL #40 X 48 PITCH W/CON

3

809-037C

CHAIN RL #40 X 58 PITCH W/CON

Front Spike Rollers

The front spike rollers should turn freely. If they do not,

investigate and remove the cause.

Trash build-up between spikes can prevent spikes from

penetrating the soil properly. Clean trash from spike

rollers as needed.

Rear Packer Roller

Refer to Figure 8-9 on page 59:

The rear packer roller assembly should be free to float up

and down to follow the field terrain. The rear roller

wheels (#3) should turn freely. If the assembly does not

float or the wheels do not turn, investigate and remove

the cause.

The rear roller wheels (#3) will wear as they slip against

on another creating gaps between the roller wheels that

should be removed. Also, the paint between the roller

wheels will wear off in the first 20 hours of operation

creating gaps that should also be removed.

39977

IMPORTANT:

The gap between rollers wheels (#3)

should be removed after the first 10 to 20 hours of

operation and as needed thereafter.

IMPORTANT:

Use only support blocks (#4 & #5) that

are made of solid hard wood or steel. Do not use

concrete blocks. Support blocks must be tall enough

to support spiked roller clamps (#2) above ground

and must also allow roller wheels (#3) and roller

clamps (#2) to turn freely.