2019-06-12

401-705M

YP3025A

169

Appendix B - Pre-Delivery

Unloading Planter

The planter is shipped on a flatbed semi-trailer, partially

lowered, with special shipping assemblies that are

removed and returned to Great Plains.

If the planter has the optional hydraulic tongue, a

solenoid valve can prevent lift at step 6. The tractor

used to unload the planter must have the

DICKEY-john

®

monitor console and CFM switch bar

installed, and the harness connected to power and

planter. This is not required for 3-point hitch.

1. Have the driver back the trailer up to a dock or ramp

long enough to allow towing the planter off the trailer

with no turns.

2. Remove any crates, pallets or loose components

beneath the planter or aft of any wheels (other than

wheel chocks).

3. Hitch a tractor to the planter (page 16). The tractor

must have hydraulic remotes for at least the lift

circuit. Set the tractor brakes.

4. Release all tie-down straps and chains. Remove any

planter wheel chocks.

5. If equipped with hydraulic tongue, put the tongue

circuit in local float (page 30).

6. Raise the planter by extending the lift cylinders. Set

lift circuit to Neutral to hold at lift.

The planter’s standard rear caster wheels will be

slightly lower than the shipping wheels. At a

depressed or pit-style dock, this may place the caster

wheels on the dock surface.

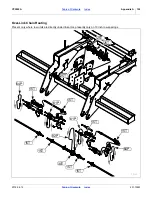

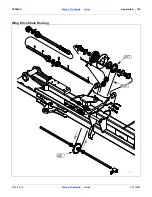

7. Remove the shorter shipping lock channels at the

gauge wheel lift cylinders, and at the center section

rockshaft lift cylinders. Replace these locks with the

longer lock channels found at the normal planter

storage locations (page 25). See table at right for

lock channel identification.

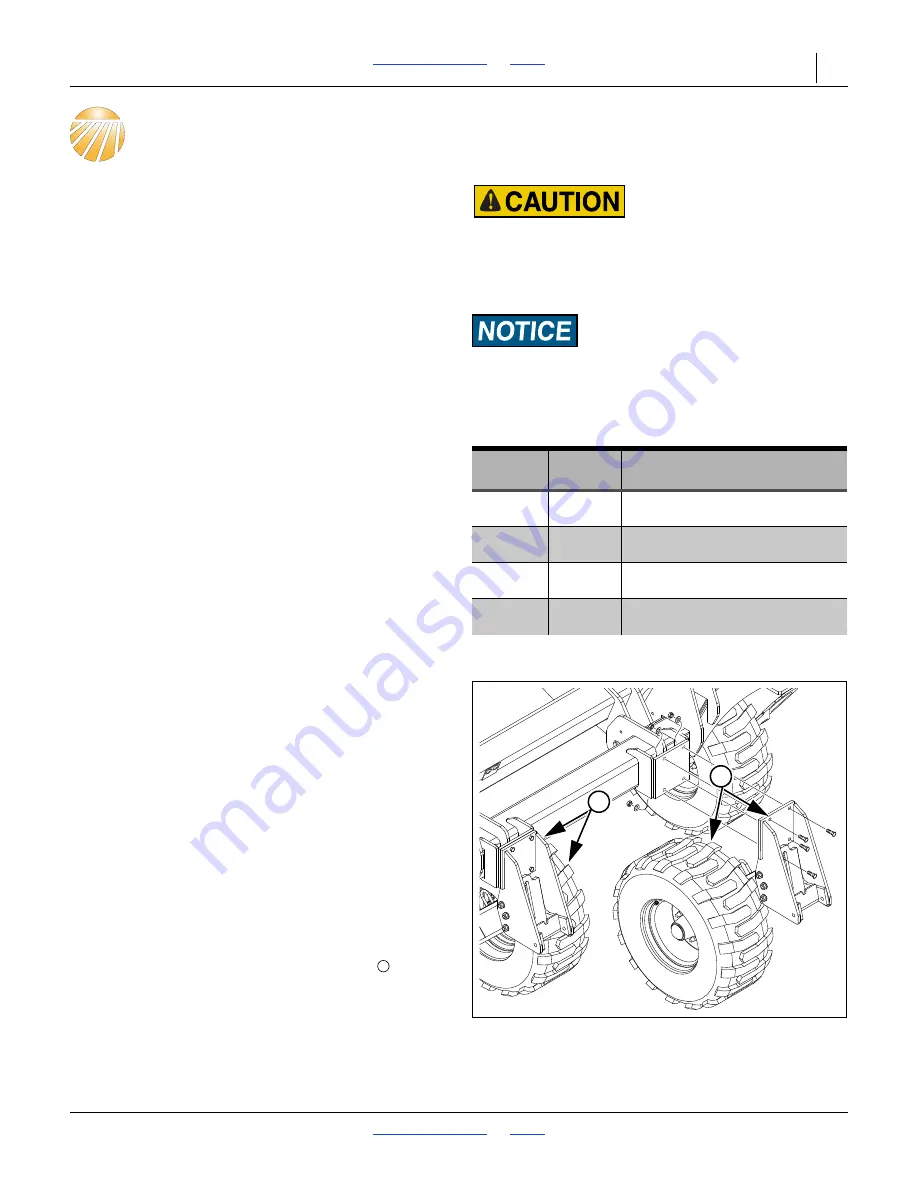

8. Remove the YP30 Shipping Stands, which are

attached via U-bolts to the front of the mainframe.

Return the stands and U-bolts to Great Plains.

9. Carefully tow the planter off the truck. Stop when

clear, or if space permits, on level ground.

Refer to Figure 138

10. Remove the shipping wheel assemblies . Return

these parts to Great Plains.

11. If the planter has one or more fertilizer manifolds,

attach the hookup mounts to the hitch plates (see

page 178). If the planter has the optional trailer hitch,

install it at the same time.

Equipment Damage Risk / Loss of Load Control Hazard:

Tow-off unload only. The planter is not designed for crane or

hoist unload from the trailer. Lifting it off the truck is likely to

result in substantial equipment damage. Loss of load control is

also possible, and could lead to serious injury or death.

Equipment Damage Risk:

Tow forward only. Shipping wheels do not caster. Reversing

with shipping wheels attached is likely to result in equipment

damage from casters colliding with shipping wheels.

Lock Channel Identification

Part /

Use

Length

Lock Channel Location /

Disposition

196-473H

shipping

12.75 in.

(32.4 cm)

Gauge wheel lift cylinder;

return to Great Plains

596-163H

shipping

9.5 in.

(24.1 cm)

Rockshaft lift cylinder;

return to Great Plains

196-292H

standard

17.75 in.

(45.1 cm)

Gauge wheel lift cylinder;

deliver with planter

402-330H

standard

16.0 in.

(40.6 cm)

Rockshaft lift cylinder;

deliver with planter

Figure 143

Shipping Wheel Weldments

31000