YP3025A

Appendix B - Pre-Delivery

171

2019-06-12

401-705M

Install Upper Marker Components

Marker disks and end tubes are removed for shipping.

The end tube may be inserted into the outer marker

arm

in any of four orientations. Great Plains

recommends that the spindle adjustment allow the disk

to pivot back, away from the direction of travel

.

If the markers are extended for this work, also set the

initial marker extension based on the row spacing.

1. At each marker, select one each:

marker disk and tube assembly

806-110C U-BOLT 5/8-11 X 3 1/32 X 4 1/2

and two sets:

803-021C NUT HEX 5/8-11 PLT

804-022C WASHER LOCK SPRING 5/8 PLT

2. Insert the end tube into the outer marker arm

.

Insert to initial marker extension value, or about

halfway if extension is not known. Secure with

U-bolt

, lock washers

and nuts

.

Dual Marker Speed Adjustment

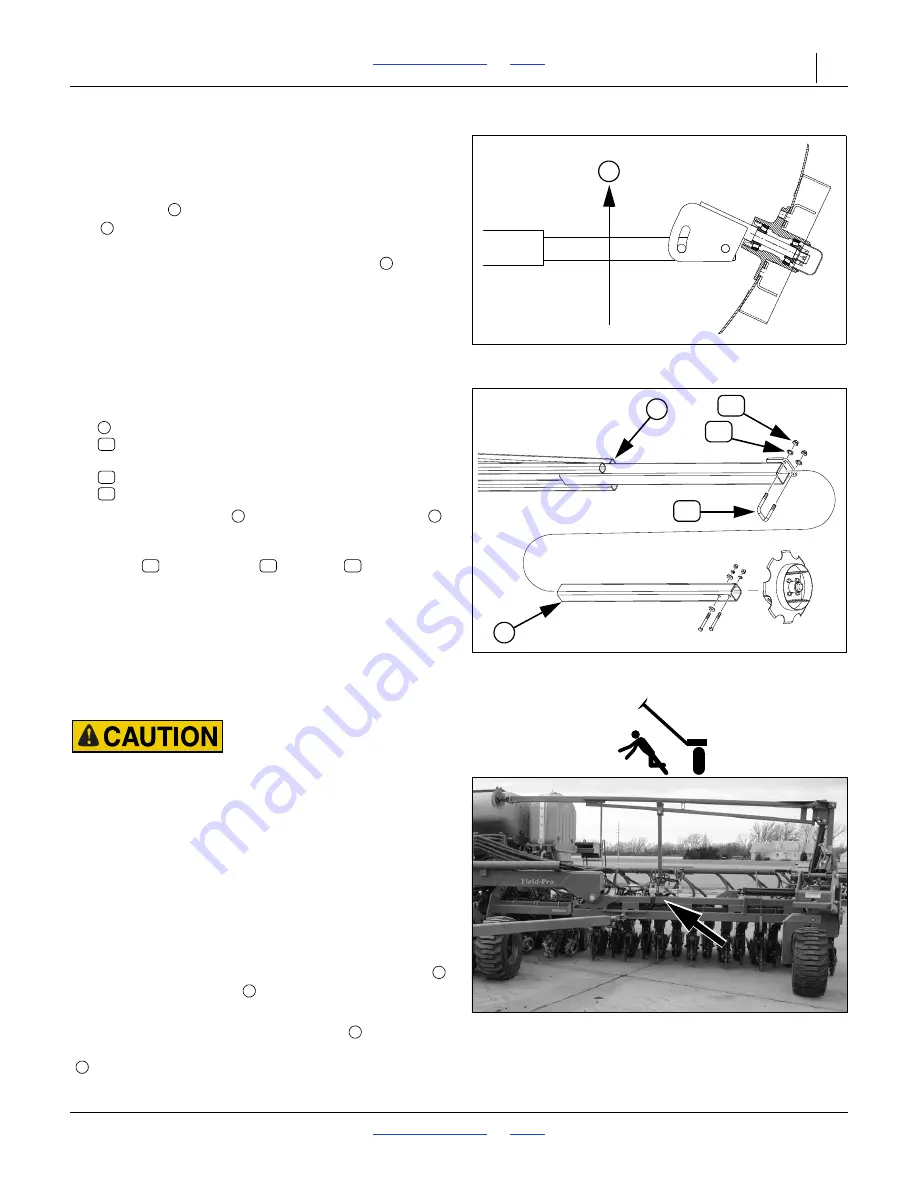

Overhead Sharp Object Hazard:

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics

fail. Never allow anyone near the Planter when folding or

unfolding the markers.

Refer to Figure 148 and Figure 149

Adjust folding speed for dual markers with hex

adjustment screws on the sequence valve body. The

valve sequence body is located on top of the left wing

frame.

Loosen jam nuts before making adjustments.

There is one adjustment screw for unfolding speed

and one for folding speed . You can identify adjustment

screws by markings stamped in valve body.

Turn adjustment screws clockwise ( : slower) to

decrease [un]folding speed and counterclockwise

( : faster) to increase [un]folding speed.

Figure 146

Marker Disk Spindle Orientation

11757

T

T

Figure 147

Marker Final Assembly

29177

36

1

35

34

2

36

34

35

36

35

34

Figure 148

Marker Sequence Valve Location

29302

1

2

S

F