YP3025A

Operating Instructions

45

2019-06-12

401-705M

Fan General Operating Information

Use tractor remote hydraulic valve flow control to set fan

speed. Always start the fan with a low flow setting.

Monitor fan rpm with the seed monitor.

Gradually bring fan up to the recommended initial rpm.

The split-air servo vane engages only above 50 rpm.

Do not run the fan over 3500 rpm or at speeds under

2000 rpm.

At excessive rpm, too much air flow can cause:

•

seed to plug the air box

•

seed suspension in a bulk seed box

•

oil heating

•

slow lift times

If the rpm is too low, the split-air system may divert

nearly all the air to the meter pressurization, leaving

none for seed transport (or just enough to plug low spots

in seed hoses).

The monitor console can report meter pressurization.

There is also a Magnehelic® air pressure gauge. These

two readings should not disagree by more than a few

tenths of an inch.

The Seed Rate manual provides initial values for

meter pressurization. Normal readings are in the

0.8 inch to 4.0 inch water pressure range, and vary

considerably with crop.

If at suggested fan rpm, desired pressure cannot be

reached, chances are the fan is running backwards. If

the rpm and meter pressurization readings are correct,

but the meters are starved of seed, the fan may be

running backwards and the meter pressurization system

is taking all the air, leaving little or none for seed delivery.

Reverse the inlet/return lines at the hitch.

If air system does not operate suitably with fan speeds

between 2000 and 3800 rpm, see “

When starting empty you must blow seed out to the

meters for two to four minutes to fill meters.

During “FILL METER”, all air is routed to the air box,

and none to the meter pressurization system.

The monitor has a level sensor below the hopper or seed

box to warn when seed box is empty. There are three to

four acres of seed in the system when the sensor first

indicates box empty, depending on seeding rate.

Steps for setting and adjusting the air system are found

at “

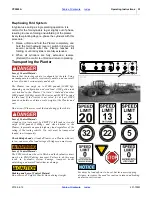

Recommended Fan Speeds

Low Population Risk at Turns:

The figures above do not include oil for lift/lower or oil for

marker operation. Aggressive lift/lower operations, and

simultaneous lift/marker operations, can reduce fan rpm below

that needed to pressurize meter disks. If seed falls out of

pockets, low population bands will occur shortly after turns.

Unless the tractor has generous oil flow capacity, raise/fold

markers before lift, and lift slowly. Watch manifold pressure

and tune operations to keep it at planting levels in turns.

Before the first planting each season, or when using new

meters or meter wheels for the first time, or at the start of each

season, before filling with seed, add

1

/

3

cup (80 ml) Ezee

Glide Plus to bottom of airbox.

YP3025A

Bulk Box

Initial Fan Speed

2700 rpm

2500 rpm

11.6 gpm

11.2 gpm

44 liters/min

42 liters/min

4.5 gpm

4.5 gpm

17 liters/min

17 liters/min

16.1 gpm

15.7 gpm

61 liters/min

59 liters/min

Fan Speed Range

2300 - 3500 rpm 2300 - 3200 rpm

9.9 - 12.9 gpm

9.9 - 12.4 gpm

37 - 49 lpm

37 - 47 lpm

4.5 gpm

4.5 gpm

17 liters/min

17 liters/min

16.1 - 15.7 gpm

14.4 - 16.9 gpm

61 - 59 lpm

54 - 64 lpm

² Does not include oil for lift/lower or markers.

Seed Hopper¹

Fan Oil

Consumption²

Hydraulic Drive Oil

Consumption²

Total² Oil, Motors,

Initial Speed

Fan Oil

Consumption²

Hydraulic Drive Oil

Consumption²

Total² Oil, Motors,

Speed Range

¹ This assumes a 2007+ Great Plains hopper, or older hopper

with the vent line update. For an older unvented hopper, use the

rpms recommended for ProBox.