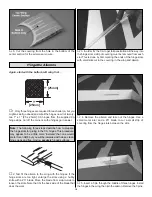

In this step, the engine is shown upright. This is only to

determine the mounting position of the engine on the mount.

Later, the engine will be mounted horizontally.

❏

3. Temporarily mount the engine mount to the firewall

with four 8-32 x 1-1/4" [32mm] socket head cap screws, #8

lock washers and #8 flat washers, but do not fully tighten the

screws. Adjust the mount spacing to fit the engine, then

tighten the screws.

❏

4. Using the appropriate brass spinner adapter that came

with this kit, fit the backplate of the included spinner onto the

engine. Position the engine on the mount so the backplate is

6-1/2" [165mm] from the firewall.

❏

5. Using a Great Planes Dead Center Hole Locator or

another suitable method, mark the location of the holes in

the engine on the mount.

❏

6. Remove the engine and mount from the firewall. Drill

holes through the mount at the marks you made with a #29

drill. Tap 8-32 threads into the holes.

❏

7. Momentarily skip ahead to page 19 and “pin” the

firewall to the fuselage by performing steps 6 and 7. When

complete, return to this page and finish mounting the engine

in step 8 below.

❏

8. Mount the engine mount to the firewall horizontally, but

do not fully tighten the screws. Mount the engine to the

mount with four 8-32 x 1" [25mm] socket head cap screws,

#8 lock washers and #8 flat washers. Center the mount

vertically, then tighten the screws.

MOUNTING A U.S. ENGINES 41CC ENGINE

❏

1. Use a straightedge and a pen to extend the horizontal and

vertical centerlines on the firewall all the way to the edges.

❏

2. Use the U.S. Engines 41cc engine mount template

on page 50 to mark the locations of the four outer holes in

the template onto the firewall. (If making a photo copy of the

template, be certain it comes out the same size as the

template and is not dimensionally distorted.) Drill 19/64"

[7.6mm] holes through the firewall at the marks.

❏

3. Use 3M spray adhesive to adhere the template to a

piece of 1/4" [6.4mm] aircraft plywood. Cut out the plywood

and drill all eight 1/4" [6.4mm] holes. Remove the template

from the plywood (naphtha lighter fluid helps this process).

❏

4. Fuelproof the engine mount with a thin coating of 30-

minute epoxy. After the epoxy hardens, bolt the engine to the

mount with 1/4-20 x 3/4" [19mm] bolts and 1/4" flat washers.

18