❏

14. Tack glue the cowl to the cowl ring by using the wood

strip to apply eight to ten evenly spaced, 1/2" long “dabs” of

epoxy to the cowl and cowl ring inside—the rest will be glued

later. This is your chance to achieve perfect cowl alignment!

View the model from all angles, making sure the cowl aligns

with the spinner and there is adequate spacing between the

cowl and spinner. Do not disturb the model until the epoxy

has hardened.

❏

15. After the epoxy has hardened, use the extended

wrench to loosen the screws and remove the cowl. (The

bottom two screws are accessible enough for removing the

cowl with the extended wrench, but they are not accessible

enough for installing the cowl without access holes which

will be cut in the next step.)

❏

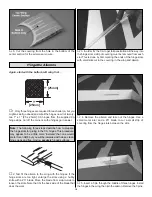

16. Using a piece of leftover wire as an alignment cue,

use a pencil to mark the holes in the bottom of the cowl for

the bottom mounting screws.

❏

17. Put on your safety glasses, ear protection, particle

mask, and a long-sleeve shirt. Use a rotary tool with a cutting

bit like the one in the photo to cut out the louvers and the holes

you marked for the extended hex wrench. Proceed slowly and

start by making the holes small, then “zero-in” on the edges

but don’t get too close. After the louvers have been cut use a

hardwood stick with a piece of medium-grit sandpaper to true

the edges. Use a round file to finish the corners. Finish by

sanding the edges of the openings with 400-grit sandpaper.

22