❏

18. Mix up another thick batch of epoxy and

microballoons. Apply a small fillet all the way around the

front of the cowl ring and the cowl. Reinstall the cowl, tighten

the screws and stand the model up on end again. Allow the

epoxy to harden.

❏

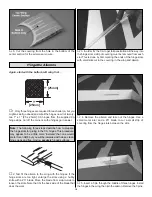

19. Remove the cowl after the epoxy has hardened. Use

coarse sandpaper to roughen the epoxy fillet. Cut the 12"

[300mm] fiberglass strip into 1-1/2" [40mm] strips, then use

30-minute epoxy to glue the strips, evenly spaced, inside the

cowl and cowl ring to reinforce the joint. While you’ve got the

epoxy out, lightly coat any other areas of bare wood on the

cowl ring. Allow the epoxy to fully harden.

❏

20. Mount the cowl and see how it all fits. The easiest way

is to insert the screws into the cowl ring, then position the

cowl and tighten the screws. When removing the cowl, the

screws should stay in the cowl ring.

❏

21. Should you prefer an extended wrench with a handle

rather than the one supplied with an “L” bend on the end,

one could be made by splicing together a 3/32" [2.4mm]

ball-end hex wrench with a piece of 4-40 pushrod and 1/8"

[3.2mm] brass tubing. Use a file to round the ends of the

wrench so they will fit into the brass tubes, then hold it all

together with silver solder.

❏

22. Now that the cowl is all fitted-up, use thin CA to

permanently join the elevators to the stabilizer and the

rudder to the fin with the hinges.

❏

Use 30-minute epoxy, 30-minute epoxy thinned with

denatured alcohol, or fuelproof paint to lightly coat the main

landing gear cutout on the bottom of the fuselage and the

exposed balsa areas of the landing gear cover. While

you’re at it, go ahead and coat any other areas on the

bottom of the fuselage that may be exposed to fuel or

exhaust residue such as the area where the wing fits and

both sides of the wing saddle. It’s not necessary to apply

heavy coats of epoxy—one light coat will do. Allow the epoxy

to soak into the wood for a few minutes, then wipe the areas

down with a few paper towel squares. Allow the epoxy to

fully harden, then lightly sand with 400-grit sandpaper.

Note: In the following steps one plywood wheel pant brace

will be glued inside each wheel pant. This significantly

strengthens the mounting area so the pants will withstand

rough fields or bouncy landings (of course, all of your landings

will be perfect!). The braces go on the inside of each pant that

gets mounted to the landing gear. Refer to the sketch at step 1

on page 27 to see how all the parts fit together.

Prepare the Wheel Pants

Fuelproof the Landing Gear Cutout

MOUNT THE LANDING GEAR

23