26

❏

7. Choose a retract servo arm

that has a hole 1/2" [13mm] from

the servo arm center. Determine

the best orientation of the servo

arm onto the servo spline so that

it is parallel with the length of the

servo case as shown in the photo

of the next step. Install a screw

lock connector using a screw lock connector retainer into

the hole that is 1/2" [13mm] from the servo arm center of the

chosen arm. Loosely thread a 4-40 x 1/8" [3mm] SHCS into

the connector. The remaining servo arms can be cut off.

❏

8. Install the servo arm onto the retract servo as shown.

❏

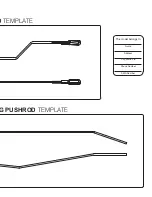

9. Make the mechanical

nose gear actuator pushrod

by threading a nylon clevis 20

turns onto a 17-1/2" [445mm]

pushrod, bending the pushrod

to clear the nose wheel. Use the

mechanical nose gear actuator

pushrod template in this manual

as a guide for the bend angles

and pushrod length.

Use the

template in

the center of

this manual as

a guide for the

bend angles

and pushrod

length.

Nylon

Clevis

17-1/2"

[445mm]

Pushrod

❏

10. Insert the pushrod through the hole you made in the

wheel well. Connect the clevis on the pushrod to the actuator

link on the nose gear retract and the other end to the screw

lock connector on the retract servo. Test the operation of the

retract servo using your radio system. Be sure that the retract

locks both in the up and down position. Make any adjustments

as necessary.

❏

11. Cut the included 5/32" x 1-1/4" [4mm x 32mm] bolt-on

axle to 1" [25mm] long as shown in the photo. Grind a fl at spot

at the end of the axle for the wheel collar set screw.