36

Balance the Model (C.G.)

More than any other factor, the

C.G.

(balance point) can

have the

greatest

effect on how a model fl ies, and may

determine whether or not your fi rst fl ight will be successful.

If you value this model and wish to enjoy it for many fl ights,

DO NOT OVERLOOK THIS IMPORTANT PROCEDURE.

A model that is not properly balanced will be unstable and

possibly unfl yable.

At this stage the model should be in ready-to-fl y condition with

all of the systems in place including the engine or brushless

motor, landing gear, and the radio system (and battery pack

if applicable).

❏

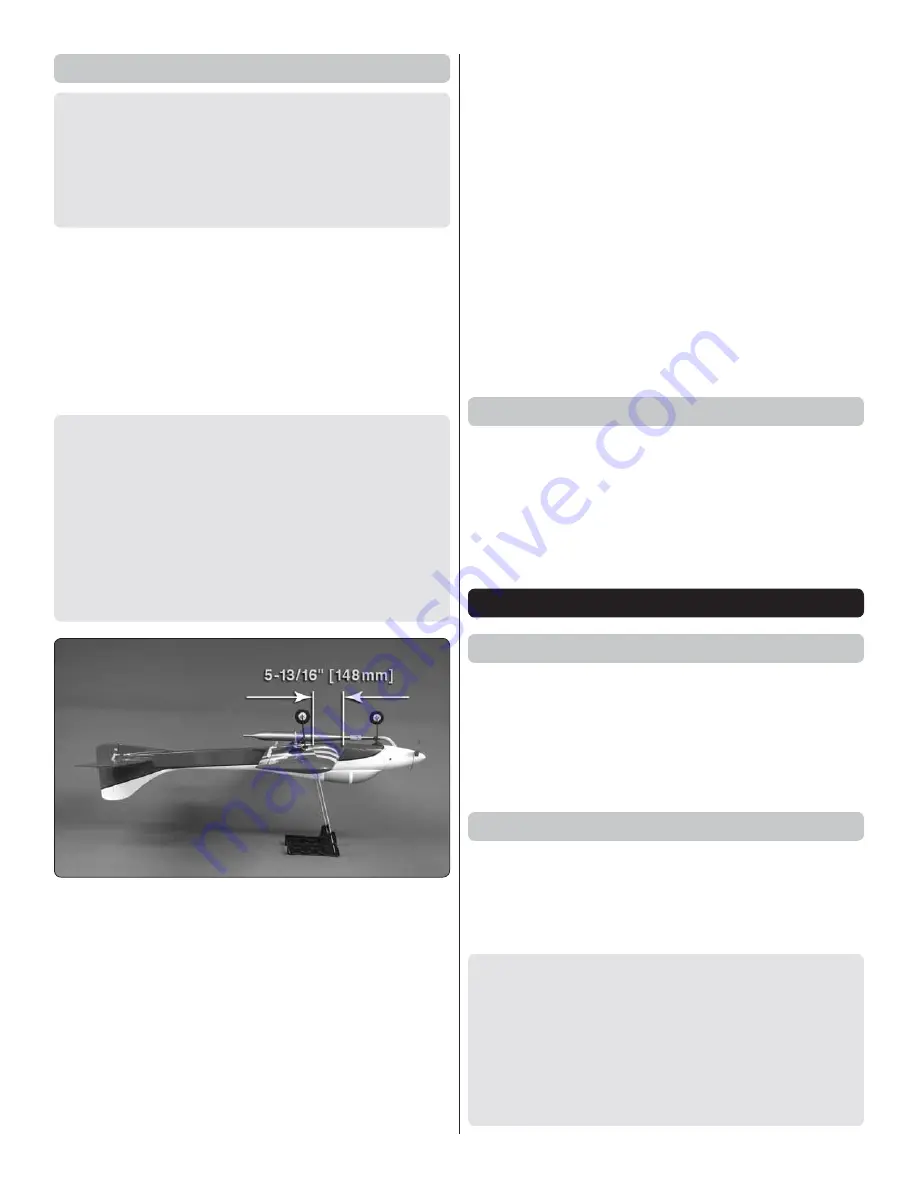

1. Use a felt-tip pen or 1/8" [3mm]-wide tape to accurately

mark the C.G. on the top of the wing on both sides of the

fuselage. The C.G. is located 5-13/16" [148mm] back from

the leading edge of the wing.

This is where your model should balance for the fi rst fl ights.

Later, you may wish to experiment by shifting the C.G. up

to 11/16" [17.5mm] forward or 11/16" [17.5mm] back to

change the fl ying characteristics. Moving the C.G. forward

may improve the smoothness and stability, but the model

may then require more speed for takeoff and make it more

diffi cult to slow for landing. Moving the C.G. aft makes

the model more maneuverable, but could also cause it to

become too diffi cult to control. In any case,

start at the

recommended balance point

and do not at any time

balance the model outside the specifi ed range.

❏

2. With the wing attached to the fuselage, all parts of the

model installed (ready to fl y) and an empty fuel tank, place

the model on a Great Planes CG Machine upside down, or

lift it at the balance point you marked.

❏

3. If the tail drops, the model is “tail heavy” and the battery

pack and/or receiver must be shifted forward or weight must

be added to the nose to balance. If the nose drops, the model

is “nose heavy” and the battery pack and/or receiver must be

shifted aft or weight must be added to the tail to balance. If

possible, relocate the battery pack and receiver to minimize or

eliminate any additional ballast required. If additional weight is

required, nose weight may be easily added by using a “spinner

weight” (GPMQ4645 for the 1 oz. [28g] weight, or GPMQ4646

for the 2 oz. [57g] weight). If spinner weight is not practical or

is not enough, use Great Planes (GPMQ4485) “stick-on” lead.

A good place to add stick-on nose weight is to the fi rewall

(don’t attach weight to the cowl—it is not intended to support

weight). Begin by placing incrementally increasing amounts

of weight on the bottom of the fuse over the fi rewall until the

model balances. Once you have determined the amount of

weight required, it can be permanently attached. If required,

tail weight may be added by cutting open the bottom of the

fuselage and gluing it permanently inside.

Note:

Do not rely upon the adhesive on the back of the lead

weight to permanently hold it in place. Over time, fuel and

exhaust residue may soften the adhesive and cause the weight

to fall off. Use #2 sheet metal screws, RTV silicone or epoxy

to permanently hold the weight in place.

❏

4.

IMPORTANT:

If you found it necessary to add any weight,

recheck the C.G. after the weight has been installed.

Balance the Model Laterally

❏

1. With the wing level, have an assistant help you lift the

model by the engine propeller shaft and the bottom of the

fuse under the TE of the fi n. Do this several times.

❏

2. If one wing always drops when you lift the model, it means

that side is heavy. Balance the airplane by adding weight to the

other wing tip.

An airplane that has been laterally balanced

will track better in loops and other maneuvers.

PREFLIGHT

Identify Your Model

No matter if you fl y at an AMA sanctioned R/C club site or

if you fl y somewhere on your own, you should always have

your name, address, telephone number and AMA number

on or inside your model. It is

required

at all AMA R/C club

fl ying sites and AMA sanctioned fl ying events. Fill out the

identifi cation tag on the center template page and place it on

or inside your model.

Charge the Batteries

Follow the battery charging instructions that came with your

radio control system to charge the batteries. You should always

charge your transmitter and receiver batteries the night before

you go fl ying, and at other times as recommended by the

radio manufacturer.

CAUTION:

Unless the instructions that came with your

radio system state differently, the

initial

charge on

new

transmitter and receiver batteries should be done for 15

hours

using the slow-charger that came with the radio

system

. This will “condition” the batteries so that the next

charge may be done using the fast-charger of your choice.

If the initial charge is done with a fast-charger the batteries

may not reach their full capacity and you may be fl ying with

batteries that are only partially charged.