16

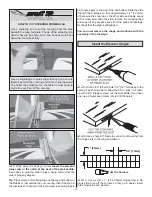

When positioned properly the control horn will rest on a

hardwood plate in the rudder. The center of the control horn

is approximately 5/8" [16mm] from the bottom of the rudder.

Mark the location of the mounting holes onto the rudder. Drill

a 1/16" [1.6mm] hole on the marks. Do not drill completely

through the rudder. Attach the control horn to the rudder

using two 2-56 x 3/4" [19mm] machine screws. Remove the

screws and apply a drop of thin CA to both holes. After the

CA has cured, reinstall the control horn.

❏

5. Slide a silicone clevis retainer over the clevis. With

the rudder servo and the rudder centered, mark the rudder

pushrod where it crosses the rudder servo arm. Make a 90°

bend at the mark. Cut the pushrod 3/8" [9.5mm] past the

bend. Attach the pushrod to the rudder servo arm with a

nylon FasLink.

❏

6. Connect the ESC, voltage regulator, rudder servo,

elevator servo and Y-harness to the receiver.

❏

7. Connect the fl ight battery to the ESC and voltage

regulator. Check that all the servos are operating correctly.

Arm the motor (with the prop removed) and slowly start the

motor to make sure it is rotating in the correct direction.

❏

8. Overlap by 1" [25mm] two strips of non adhesive backed

hook and loop material. Route the hook and loop material

through the slot in the battery tray, under the tray and back

through the slot on the other side of the tray.

❏

9. Attach a strip of sticky backed hook material to the

center of the battery tray. The loop material can be attached

to the battery.

Apply the Decals

The box photographs show the location of the decals on

the airplane. Refer to the box for the exact placement of the

decals. The following tips may be useful for applying them.

1. Be certain the model is clean and free from oily fi ngerprints

and dust. Prepare a dishpan or small bucket with a mixture

of liquid dish soap and warm water–about one teaspoon of

soap per gallon of water. Submerse the decal in the soap and

water and peel off the paper backing. Note: Even though the

decals have a “sticky-back” and are not the water transfer

type, submersing them in soap and water allows accurate

positioning and reduces air bubbles underneath.

2. Position decals on the model. Holding the decal down, use

a paper towel to wipe most of the water away.

3. Use a piece of soft balsa or something similar to squeegee

remaining water from under the decal. Apply the rest of the

decals the same way.

GET THE MODEL READY TO FLY

Check the Control Directions

❏

1. Turn on the transmitter and receiver and center the

trims. If necessary, remove the servo arms from the servos

and reposition them so they are centered. Reinstall the

screws that hold on the servo arms.

❏

2. With the transmitter and receiver still on, check all the

control surfaces to see if they are centered. If necessary, adjust

the clevises on the pushrods to center the control surfaces.