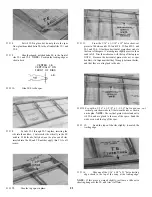

D 24. Sand all balsa parts flat and even with the front of

F-l. Also sand the rear edge of the fuse top front even with

the rear edge of F-3.

SAND THE FUSELAGE

D

25. Glue the four layers of the balsa nose block

together, alternating the grain direction at each layer (you are

making balsa "plywood"). NOTE: Use thin CA to achieve

good penetration, making a hard and durable nose block.

After the glue has hardened, sand the inside of the openings

with sandpaper wrapped around a dowel.

D 1. Carefully sand the vertical grain balsa battery

compartment doublers even with the fuse sides in the wing

saddle area.

D 26. Glue the laminated nose block to the front of the

fuse. NOTE: The layer having vertical grain should be in

the front. NOTE: If you are installing a landing gear (and

tail skid), perform steps 27 and 28 now.

D

D 27. Cut a scrap of 1/8 " ply (from die-cutting scrap) to

fit snugly between the 1/8" x 1/8" balsa stringers at the aft

end of the fuse. Glue in place.

D

D

D 28. Glue the die-cut 1/16" ply tail skid plate to the

bottom of the fuse at the aft end. Then sand the tail skid parts

even with the fuse sides and fuse tail end.

2. Note that the 1/2" balsa triangle stringers protrude

above the fuse sides in the stab saddle area. Sand these

triangles down even with the fuse sides in the stab saddle

area.

3. Study the cross-section drawings of the formers

and cross-sections "E-E" and "F-F" to get a "feel" for how

much sanding will have to be done on the fuselage to produce

the correct shapes. Now use a sanding block with coarse

(#50 or #80 grit) sandpaper to sand the fuselage to its

approximately final shape.

4. Change to progressively finer grades of sandpaper

to achieve the final shape and smoothness. If you cut a long,

narrow strip (1" x 10") of 400-grit sandpaper and use it like

a "shoe-shine cloth" on the top of the fuse, you will be

surprised at the uniformity and smoothness that can be

achieved.

12