11

❏

9. Use a few dabs of clear RTV silicone, R/C 56 canopy

glue or double-sided adhesive tape to hold the canopy to the

top of the wing or to the doubler.

Note:

Non-permanent glue

is recommended to allow for easy removal of the canopy in

the future.

GET THE MODEL READY TO FLY

Check the Control Throws

If the pushrods were connected to the servo arms as

previously illustrated, then the control throws should already

be correct, or very nearly correct. However, it is still a good

idea to check the throws since they have such a great effect

on how the model fl ies.

❏

1.

Make sure the throttle stick is all the way down

so

you do not accidentally arm or start the motor. Turn on your

transmitter and connect a battery to the ESC.

❏

2. Make sure the ailerons, elevator and rudder are centered.

If necessary, adjust the pushrods in the screw-lock connectors

to center the controls and re-tighten the screws in the

screw-locks.

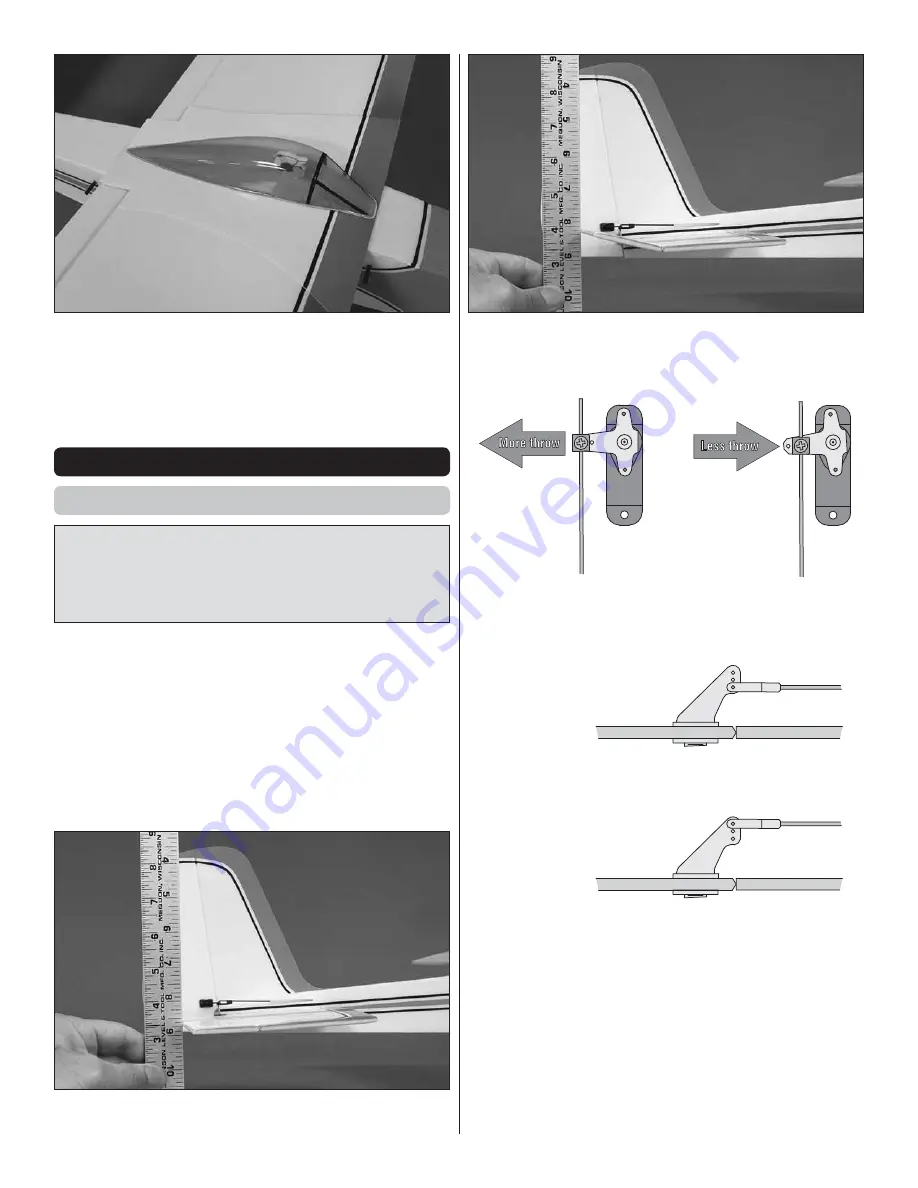

Measure the elevator throw fi rst…

❏

3. Hold a ruler to the trailing edge of the elevator. Note the

measurement.

❏

4. Use the transmitter to move the elevator to full “up” and

note how far the elevator moved. This is the “up” elevator throw.

On the servo, move the pushrod

out

to increase throw,

or

in

to decrease throw.

On the control surface,

move the pushrod

in

to increase throw,

or

out

to decrease throw.

More throw

Less throw

❏

5. Make sure the up elevator throw you measured is the

same as the throw specifi ed on the following page. Measure

the down elevator throw and the rudder and aileron throw the

same way for both the high and low rates. If the throws on your

plane are within 1/8" [3mm] of the specifi ed throws, go ahead

and fi ne-tune the throws using the End Point adjustments

in your transmitter. If the throws are too far off, change the

throws by relocating the pushrods on the servo arms and/or

control horns on the surfaces. Moving the pushrods inward

on the servos or outward on the control surfaces will provide

less throw and moving the pushrods outward on the servos

or inward on the control surfaces will provide more throw.

Summary of Contents for EP FALCON ARF

Page 16: ......