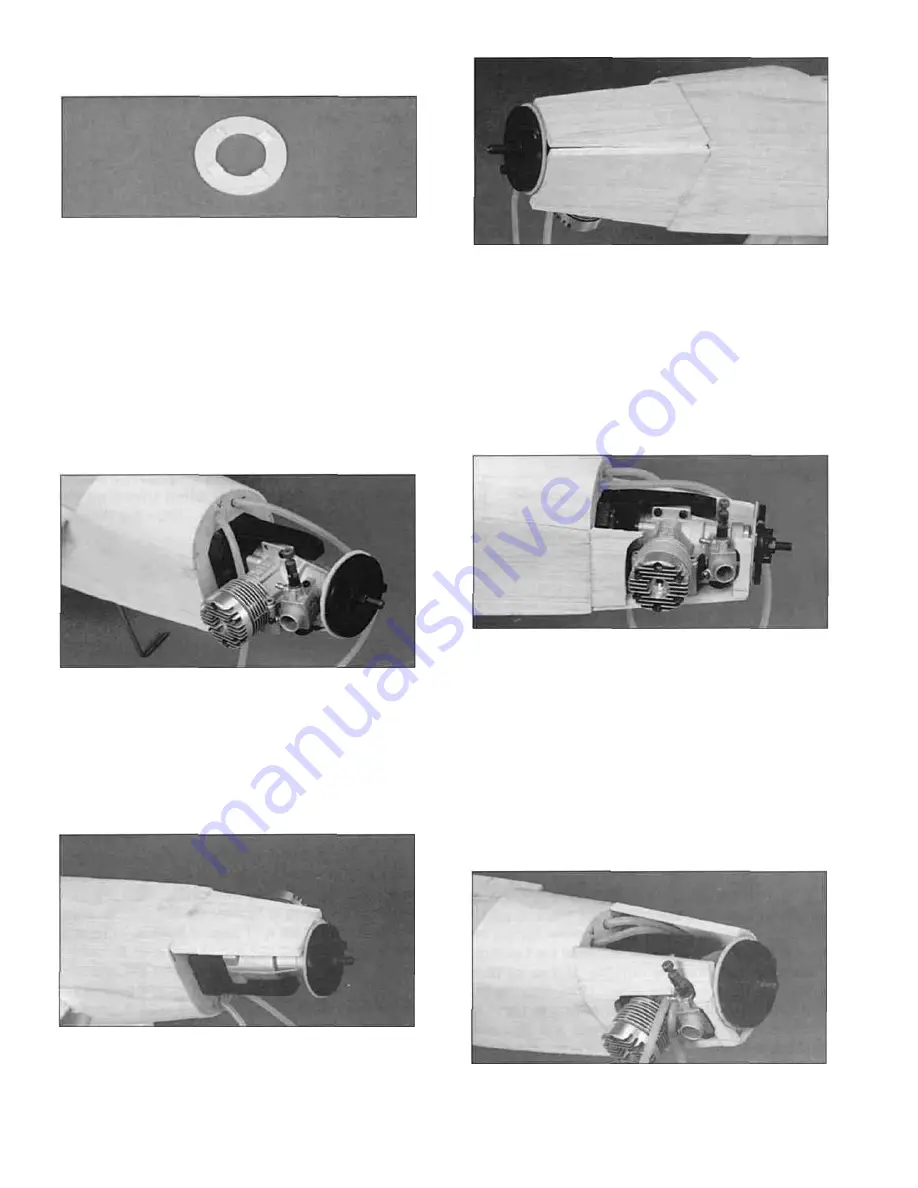

BUILD THE NOSE SECTION

D 1. From a scrap of 1/16" balsa, cut four small

pieces and tack glue them to the die-cut 1/16" ply

spinner ring (F154F19) as shown, using a small

amount of thick CA.

D 2. Center your 2-1/4" diameter spinner

backplate (Hobbico HCAQ3750 "Jet Spinner"

recommended) over the spinner ring and tack glue

it to the 1/16" balsa.

D 5. Sand a 1/4" balsa shaped nose side

(F154F130) to fit on the left side of the nose (the

side opposite the engine head) and glue it in place.

Notice that it is not glued flush with the fuse side or

outside edge of the spinner ring but protrudes

approximately 3/32". This allows the nose side to

be sanded to a curved shape.

D 3. Slide the spinner ring / spinner backplate

assembly onto the crankshaft and temporarily hold

it in place with the prop nut and a couple washers

if necessary.

D 6. Cut the remaining 1/4" balsa shaped nose

side as needed to fit around the engine. Do not

worry about getting a tight fit around the engine

because you still have to be able to get the engine

in and out. Just cut pieces to fit between the

spinner ring and the carb and another to fit

between the head and the firewall. Leave at least

a 3/16" gap all around the engine.

D 4. Sand a 1/4" balsa shaped nose bottom

(F154F23) to fit between the spinner ring and the

firewall. Glue it in place as shown in the photo. Be

careful so you don't warp the spinner ring while

doing this.

D 7. Install two side 1/4" balsa nose tops

(F154F25) by beveling the bottom edge to fit

against the nose sides and gluing them in place.

22

Summary of Contents for F-15 EAGLE

Page 7: ...6 DIE CUT PATTERNS ...

Page 53: ...TWO VIEW DIAGRAM ...