D 10. Sheet the opposite wing panel using the

same procedure outlined above.

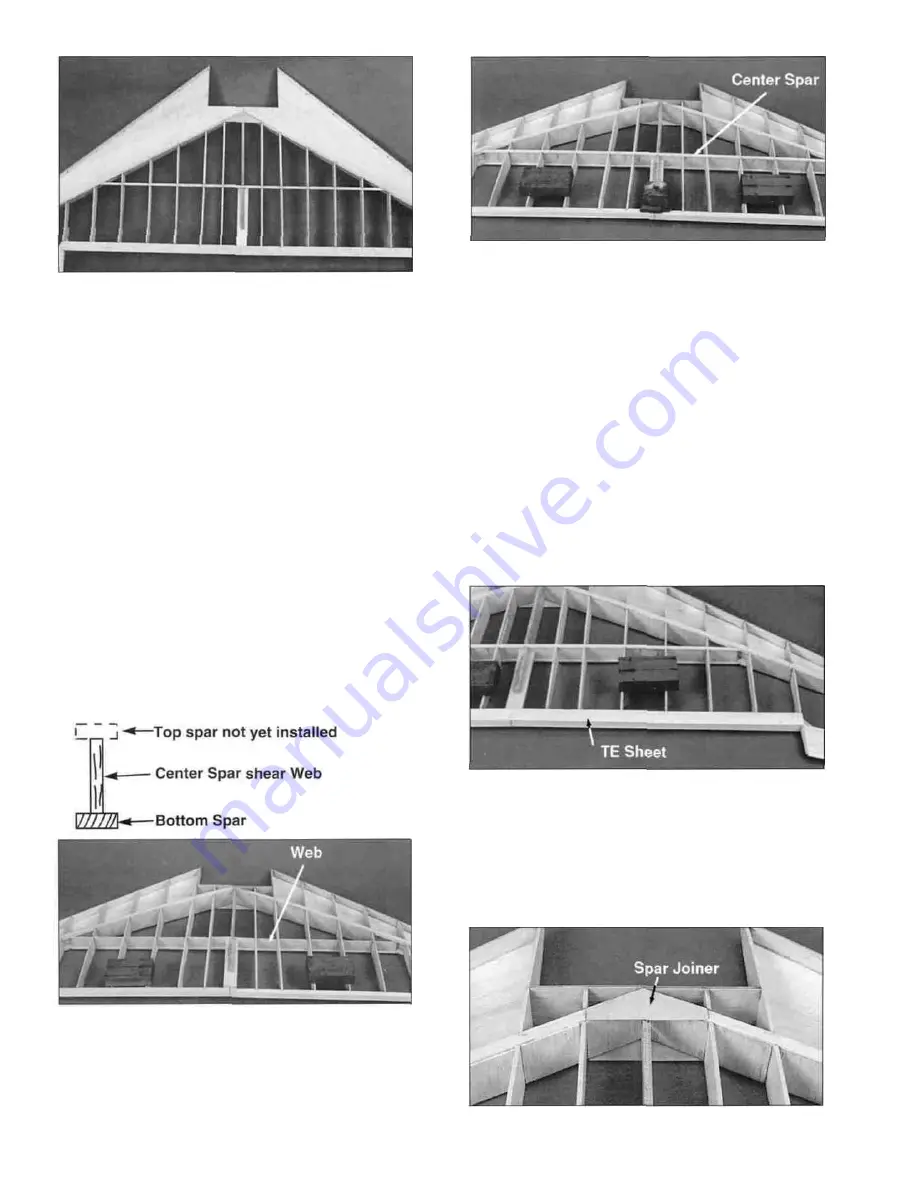

INSTALL THE BOTTOM WING

SHEETING

D 1. Flip the wing over and carefully trim off the

jig tabs on the bottom of the wing (the side

opposite of the side you just sheeted). Also trim

the shear webs flush with the spar and cut the

bottom spar off flush with rib 10. Use a sanding

block with fine grit sandpaper to touch up where

the jig-tabs were and to blend the ribs into the TE.

Be careful not to change the shape of the ribs

during this step.

D 2. Install the 1/16" x 2-15/16" x 1" balsa

center spar shear webs (F154W19) by securely

gluing them to the top center spar in all the rib

bays. Cut them to fit when required and make

sure they are in full contact with the spar. Notice

that they are glued to the bottom of the spar

and not the front or back.

D 3. Cut the remaining 1/8" x 1/4" x 30"

basswood center spar (F154W09) to fit as you did

earlier on the top surface. Apply a bead of thick

CA on the top surface of all the center spar shear

webs and install the center spar. Make sure all the

jig-tabs are on the work surface and the center

spar is pressed down against the shear webs.

NOTE: The spar need not be flush with the bottom

edge of the ribs. Make a glue fillet around the

center spar where it contacts the main spars. After

the glue is fully cured, remove the wing from the

work surface and inspect the shear web joints.

Add medium CA to the joints if necessary to

achieve good strong joints. Replace the wing on

the work surface.

D 4. Add the remaining two 1/16" x 7/8" x 18"

balsa TE sheets (F154W15) just as you did earlier

on the top surface. Do one panel at a time and

keep the wing flat on the work surface until the

glue cures.

D 5. Sand the area near where the main spars

35

Summary of Contents for F-15 EAGLE

Page 7: ...6 DIE CUT PATTERNS ...

Page 53: ...TWO VIEW DIAGRAM ...