4

ADDITIONAL ITEMS REQUIRED

Required Adhesives & Building Supplies

This is the list of adhesives and building supplies required to

fi nish the Factor 3D EP ARF.

Order numbers are provided in

parentheses.

❍

1/2 oz. [15 g ] Thin Pro CA (GPMR6001)

❍

1/2 oz. [15 g ] Medium Pro CA+ (GPMR6007)

❍

Drill bits: 1/16" [1.6 mm], 5/64" [ 2 mm]

❍

#1 Hobby knife (HCAR0105)

❍

#11 blades (5-pack, HCAR0211)

❍

Small T-pins (100, HCAR5100)

Optional Supplies and Tools

Here is a list of optional tools mentioned in the manual that

will help you build the Factor 3D EP ARF 580 EP.

❍

Pro 30-minute epoxy (GPMR6047)

❍

Denatured alcohol (for epoxy clean up)

❍

2 oz. [ 57 g ] spray CA activator (GPMR6035)

❍

CA applicator tips (HCAR3780)

❍

CA debonder (GPMR6039)

❍

Epoxy brushes (6, GPMR8060)

❍

Mixing sticks (50, GPMR8055)

❍

Mixing cups (GPMR8056)

❍

Threadlocker thread locking cement (GPMR6060)

❍

AccuThrow

™

Defl ection Gauge (GPMR2405)

❍

CG Machine

™

(GPMR2400)

❍

21

st

Century

®

sealing iron [COCR2700]

❍

21

st

Century iron cover [COVR2702]

IMPORTANT BUILDING NOTES

●

There are two types of screws used in this kit:

Sheet Metal Screws

are designated by a number and a

length. For example #6

3/4" [19mm].

This is a number six screw

that is 3/4" [19 mm] long.

Machine Screws

are designated by a number,

threads per inch,

and a length. For example

4-40

3/4" [19mm].

This is a number four screw

that is 3/4" [19 mm] long with

forty threads per inch.

●

When you see the term

test fi t

in the instructions, it means

that you should fi rst position the part on the assembly

without using any glue

, then slightly modify or

custom

fi t

the part as necessary for the best fi t.

●

Whenever the term

glue

is written you should rely upon

your experience to decide what type of glue to use. When

a specifi c type of adhesive works best for that step, the

instructions will make a recommendation.

●

We recommend 30-minute epoxy only, because you will

need the working time or the additional strength

●

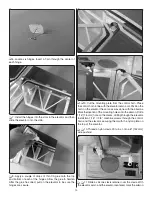

Photos

and

sketches

are placed

before

the step they refer

to. Frequently you can study photos in following steps to

get another view of the same parts.

KIT INSPECTION

Before starting to build, take an inventory of this kit to make

sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not

of acceptable quality, or if you need assistance with assembly,

contact

Product Support

. When reporting defective or missing

parts, use the part names exactly as they are written in the

Kit Contents list.

Great Planes Product Support

3002 N Apollo Drive, Suite 1

Ph: (217) 398-8970, ext. 5

Champaign, IL 61822

Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

ORDERING REPLACEMENT PARTS

Replacement parts for the Great Planes Factor 3D EP ARF

are available using the order numbers in the

Replacement

Parts List

that follows. The fastest, most economical service

can be provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Hobbico web site at www.

hobbico.com. Choose “Where to Buy” at the bottom of the menu

on the left side of the page. Follow the instructions provided

on the page to locate a U.S., Canadian or International dealer.

If a hobby shop is not available, replacement parts may also

be ordered from Tower Hobbies at www.towerhobbies.com,

or by calling toll free (800) 637-6050.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721, but

full retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax.

If ordering via fax, include a Visa or MasterCard number and

expiration date for payment.

Mail parts orders

Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822