6

PREPARATIONS

❏

1. If you have not done so already, remove the major

parts of the kit from the box and inspect for damage. If any

parts are damaged or missing, contact Product Support at

the address or telephone number listed in the “Kit Inspection”

section on page 4.

❏

2. Remove the tape and separate the elevators from the

stab. Use a covering iron with a covering sock on medium

heat to tighten the covering on the wings, fuselage, etc. if

necessary. Apply pressure over sheeted areas to

thoroughly

bond the covering to the wood.

Caution:

The Factor 3D EP

ARF was designed to be strong where needed, but light weight

for excellent fl ight performance. Care must be taken when

assembling the plane to avoid damage.

ASSEMBLE THE WINGS

Install the Ailerons

Do the right wing fi rst so your work matches the photos

the fi rst time through.

Install the Aileron Servos and Pushrods

❏ ❏

1. Inside the servo bay a string is taped. Carefully

remove the tape and string from the servo bay. Tie the string

to the servo lead. Pull the string and the servo lead through

the wing. Untie the string from the lead.

❏ ❏

2. Install the servo into the servo opening. Drill a 1/16"

[1.6 mm] hole though the servo mount, into the wood in the

wing. Install and then remove a servo mounting screw into

each of the holes you have drilled. Apply a drop of thin CA

into the holes to harden the threads. Once the glue has cured

install the servo into the servo opening. Center the servo and

then install a servo arm as shown. The arm should be pointing

towards the wing root.

❏ ❏

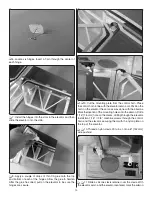

3. Drill a 5/64" [ 2 mm ] hole through the hole in the servo

arm as shown.

❏ ❏

4. Thread a nylon clevis, 20 turns, onto a 6

"

[152 mm]

wire pushrod.

Hinge Line

Hinge Line

Correct

Incorrect

Refer to this picture for steps 5-7.

❏ ❏

5. Cut the

mounting plate from

the control hor n.

Attach the clevis in the

outer hole of a nylon

control horn. Place

the control horn in line

with hole you drilled in

the servo arm. When

positioned properly

the control horn will

rest on a hardwood

plate in the aileron.

Mark the location of

the mounting holes

onto the aileron. Drill

a 1/16" [1.6 mm ] hole

on the marks, drilling

through the plywood

plate but not through

the top of the aileron.