17

the propeller and the cowl. Make adjustments if necessary.

(The outside edges of the cowl ring may be sanded slightly

to allow the cowl to go on a little farther if necessary.)

❏

5. Remove the cowl and take the cowl ring off the fuselage.

Use medium-grit sandpaper to roughen the inside of the

cowl where the cowl ring fi ts. Lightly spray the inside of

the cowl and the front of the cowl ring with CA accelerator.

This will prevent excess CA from getting past the cowl ring

inadvertently gluing it to the fuselage. Reinstall the cowl

ring and cowl.

❏

6. Stand the fuselage upright with the nose pointing up.

Drip a few small drops of thick or medium CA down inside

the cowl where it contacts the cowl ring – this won’t be the

fi nal glue job – just enough to tack the cowl to the cowl ring.

You won’t be able to reach the part of the cowl ring in the

upper left-hand corner, but that can be glued in the next step.

❏

7. Remove the cowl/cowl ring assembly. Securely glue

the cowl ring to the inside of the cowl with medium CA. Add

a small amount of thin CA around the back of the cowl ring

– do not build up a fi llet of glue here or it may interfere with

the fi t of the cowl.

❏

8. If you’re using a glow engine, fuelproof the cowl ring

with epoxy thinned with denatured alcohol or any other

fuelproof coating.

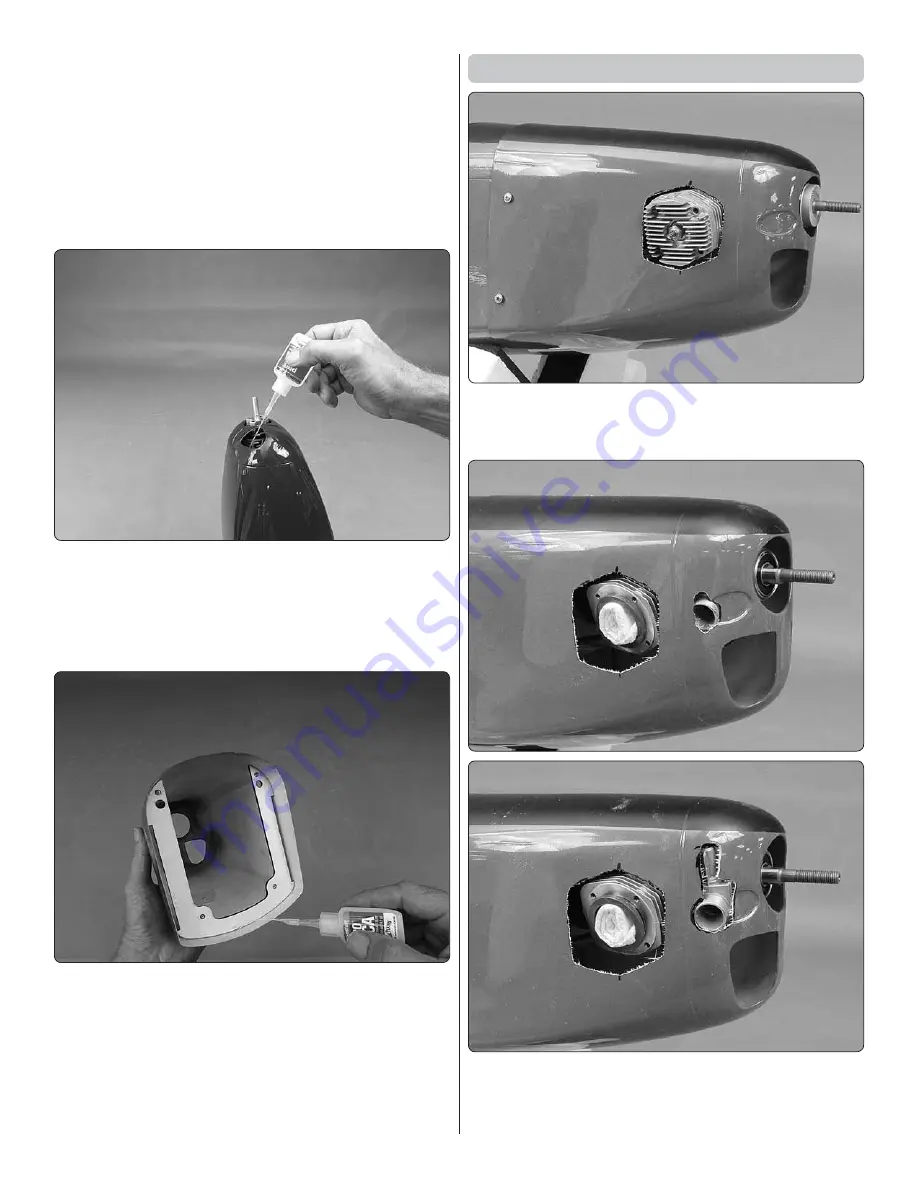

Finish Cutting the Cowl

❏

1. Now that the cowl has been mounted and its

exact location has been set, continue to cut the cowl to

accommodate the head of the engine.

❏

2. Now install the carburetor. Mark, cut and fi t the cowl

as necessary.

❏

3. Next, cut a hole for the needle valve.