9

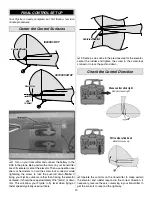

Mount the Servos

It’s okay to cut out this

part to make it easier

to fit larger servos.

Servo Tray

❏

1. If

not

using the recommended ES40 Pico servos, test fi t

the servos you will be using in the servo tray in the fuselage.

If your servos don’t fi t, use a hobby knife to carefully trim the

tray as necessary—if it makes the trimming job easier you

can cut out the center part of the tray.

Cut off

Trim the corners

ES40 Pico Servos

Make two

3/8" [9.5mm]

“Other” Servo Arm

❏

2. If you are using the recommended ElectriFly ES40 Pico

servos, prepare the servo arms that came with the servos by

cutting them as illustrated. If

not

using Pico servos, prepare

two servo arms so the pushrod mounting holes will be 3/8"

[9.5mm] from the arm mounting screw.

❏

3. Mount a screw-lock connector to each servo arm using

the small, black nylon retainer—if the screw-lock connectors

don’t fi t in the servo arm holes use a #55 drill or a hobby

knife to carefully enlarge the holes

just enough

to fi t the

micro screw-lock connector. Thread a 2mm x 4mm Phillips

machine screw into each screw-lock connector.

Use this photo for the next two steps:

❏

4. Connect the rudder and elevator servos to the

receiver—the servo on the right is the rudder servo and goes

to

channel 1

in the receiver and the servo on the left is the

elevator servo and goes to

channel 2

in the receiver.

Not Good

Too far from 90°

Acceptable

Close enough to 90°

99°

95°

90°

90°

95°

99°

Perfect

90°

❏

5. Turn on your transmitter and make sure the trims are

centered. Connect the battery to the ESC. This will “center”

the servos. Fit the servo arms onto the servos so they will be

as close as you can get them to 90° to the pushrods—it may

not be possible to get the servo arms

precisely

90°, so just

get them as close as you can. This will provide symmetrical

control surface throw (discussed on page 14).

Pressed all the way down

NO

YES

❏

6. Make sure the servo arms are fi rmly pressed

all the

way down

onto the splined shafts and install the screws that

hold on the arms.