aileron servo into a 610mm [24"] Y-harness and tie the string

around the other aileron plug. Be sure to secure the left

aileron connection with heat-shrink tubing.

❏

7. Lightly pull the other end of the string until the

“Y” section is near the small opening near the center of the

top wing. Carefully use a bent paper clip or some type of

grasping device to carefully pull out the connector for the

receiver. Leave the right aileron connector tied to the string.

❏

8. Continue pulling the string until the right aileron

connector enters the right aileron bay. Disconnect the string

and plug in the right aileron servo. Secure the connection

with heat-shrink tubing.

❏

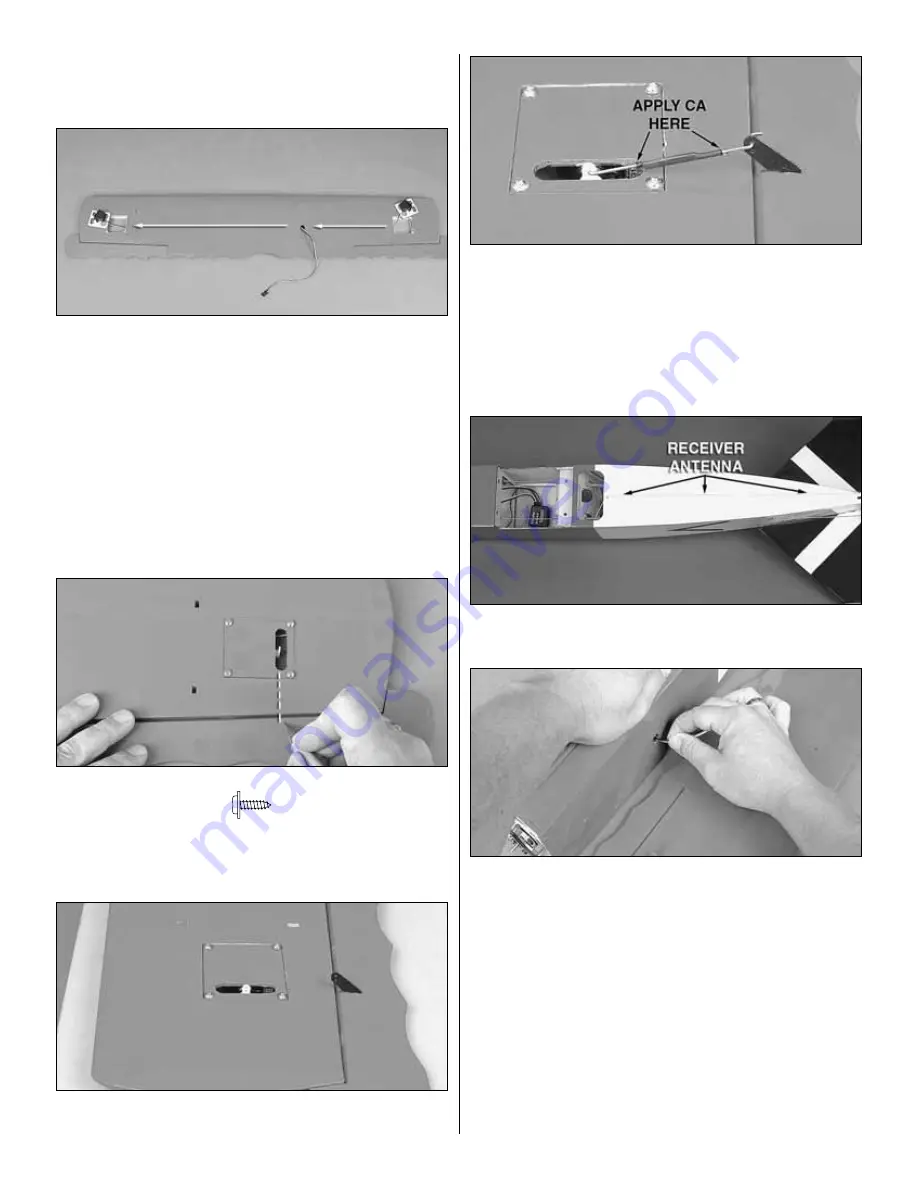

9. Secure each aileron servo hatch to the wing with four

2mm x 7mm [5/64" x 9/32"] self-tapping washer head screws.

❏

10. Use a sharp hobby knife to trim the covering from over

the small rectangular hole along the LE of each aileron as

shown. Do not cut all the way through the ailerons.

❏

11. Test fit the control horns and when satisfied with their

fit, CA them in place as shown.

❏

12. Install one 35mm [1-3/8"] aileron pushrod in the outer

hole of the aileron servo arm and another in the outer hole

of the aileron control horn. Slide one of the included pieces

of heat-shrink tubing over the pushrods. With the radio

system on and the aileron servo trim lever centered, shrink

the heat-shrink tubing over the pushrods and apply a couple

of drops of thin CA to the tubing. Note: A hot soldering iron

works great for shrinking the heat-shrink tubing.

❏

13. Make a small hole in the bottom sheeting. Route the

antenna out of the hole and tape it to the bottom of the fuselage.

❏

14. Plug a 152mm [6"] servo extension into the receiver

securing it with heat-shrink tubing, tape or other method to

secure the connection. Route the servo extension through the

hole in the left side of the fuselage. Re-install the bottom wing.

12