servo. Mark the location for the screw holes. Drill through the

marks you made with a 1/16" [1.6mm] drill bit. (Be sure you

are drilling into the plywood plate mounted in the bottom of

the aileron. Drill through the plate only. Do not drill all the

way through the aileron!) Using a #2 x 1/2" [#2 x 13mm]

sheet metal screw, install and then remove a screw into each

of the holes. Harden the holes with thin CA. Install the control

horn with four #2 x 1/2" [#2 x 13mm] sheet metal screws.

❏ ❏

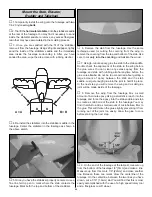

6. Locate a .074" x 6" [.074" x 152mm] pushrod wire

threaded on one end. Screw a nylon clevis onto the threaded

end of the wire 20 turns. Install a silicone clevis keeper onto

the clevis. Then, install the clevis on the aileron control horn.

❏ ❏

7. Be sure the aileron servo is centered. Enlarge the

first hole in the servo arm with a Hobbico Servo Horn Drill

(or a #48 or 5/64" [2mm] drill bit). Center the aileron and

align the wire pushrod with the hole in the end of the servo

arm. Using a marker, mark the location where the wire aligns

with the hole in the servo arm. On that mark make a 90

degree bend. From the bend measure an additional 3/16"

[4.8mm] and then cut off the excess pushrod wire.

❏ ❏

8. Install the wire into the hole in the servo arm using

a nylon FasLink

™

as shown in the sketch.

❏

9. Repeat steps 1-8 for the left wing panel.

❏

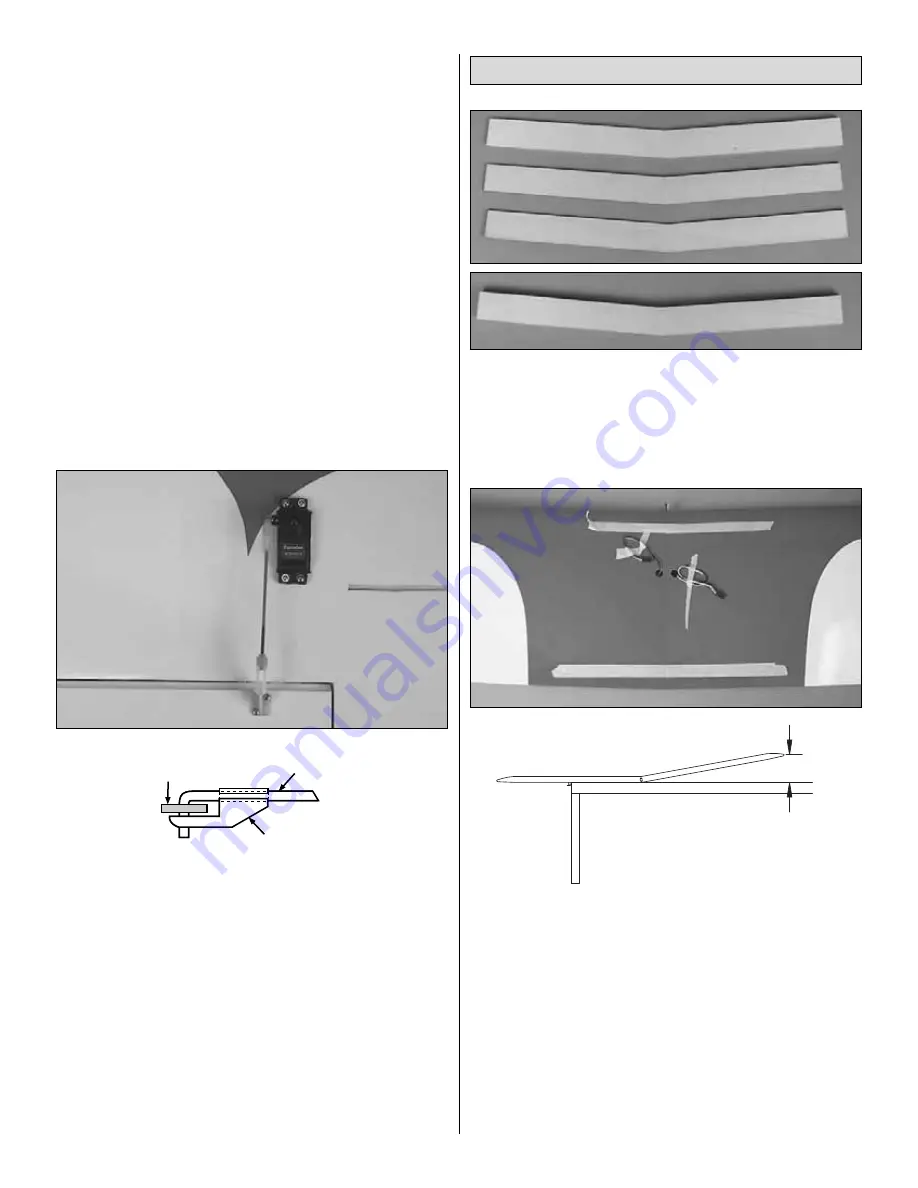

1. Locate the three hardwood wing joiners. Using 5-minute

epoxy, glue them together forming one 1/4" [6mm] wing joiner.

❏

2. Test fit the wing joiner into each wing panel, making

sure that it is not too tight. Sand the joiner as needed to get

a good fit.

❏

3. Apply 30-minute epoxy to both sides of the wing joiner, the

joiner pocket in both wing panels and to the root rib of each

wing panel. Push the wing panels together and hold them in

place with masking tape. Before the glue cures, set the wing flat

on your bench and measure the dihedral. The distance from the

top of the bench to the center of the wing as measured at the

wingtip should be approximately 6" [152mm]. Block the wingtip

up while the glue cures.

Note: Due to production techniques

there may be some variance in the actual dihedral of each

model. Our prototypes flew well with the dihedral anywhere

between 5-3/4" and 6-1/4" [146mm and 159mm].

❏

4. Set the wing aside allowing the glue to cure.

Workbench

6"

Join the Wings

FasLink

2-56 (.074") Pushrod Wire

Servo Horn

10