❏

4. 1/16" [1.6mm] inside the lines you have drawn cut a 3/4"

[19mm] wide strip of covering from the wing. Use a sharp #11

hobby knife or use the Expert Tip that follows to cut the

covering from the wing along the lines you marked. Use care

to cut only into the covering and not into the wood.

How to cut covering from balsa.

Use a soldering iron to cut the covering from the stab. The

tip of the soldering iron doesn't have to be sharp, but a fine

tip does work best. Allow the iron to heat fully. Use a

straightedge to guide the soldering iron at a rate that will just

melt the covering and not burn into the wood. The hotter the

soldering iron, the faster it must travel to melt a fine cut. Peel

off the covering (see the photo at step 4).

❏

5. Where the belly pan contacts the wing, sand the inside

of the belly pan with 220-grit sandpaper and then wipe the

residue clean with rubbing alcohol. After the alcohol has

dried, glue the belly pan to the wing with 6-minute epoxy.You

will find it easier to glue one side at a time rather than trying

to do both sides together.

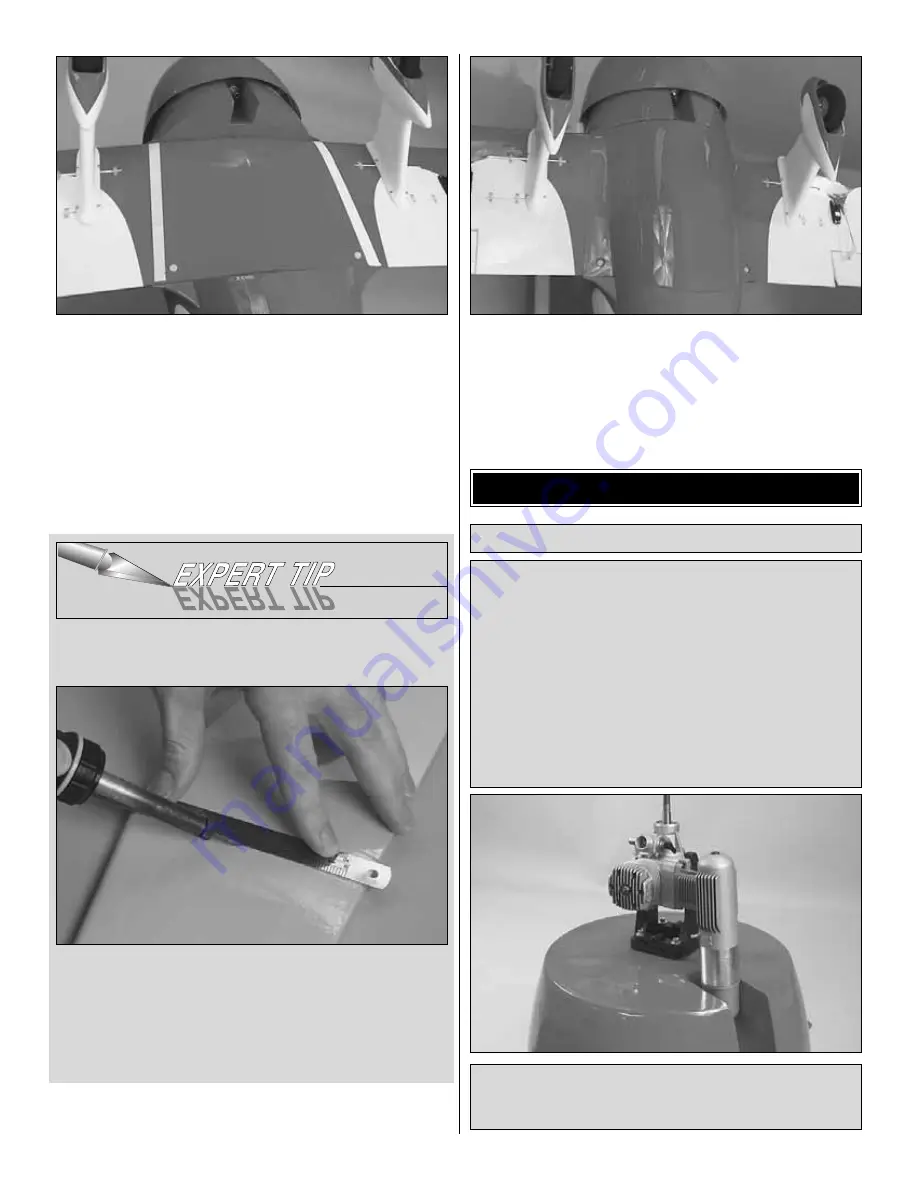

If you are using the O.S. .91 two-stroke engine you will

need to use a muffler extension (OSMG2582) to help

clear the bottom of the fuselage.

You now need to make a few decisions about the engine

installation. Provided on page 35 in this instruction manual

are two different engine mounting templates. One is for the

O.S. 1.20 four-stroke engine and the other is for the O.S.

.91 two-stroke engine. If you are using another brand of

engine or engine mount you will have to do some

measuring and use the reference marks in the fuselage to

center the mount for your engine. The large opening in the

bottom of the fuselage is to provide an easy exit for most

standard mufflers. The engine mounting templates position

the engines to allow the muffler on the O.S. 1.20 or the

O.S. .91 to exit through this opening.

Install the Engine and Throttle Servo

ASSEMBLE THE FUSELAGE

14