❏

17. Place the cowl onto the ring, centering the cowl on

the engine. Do not push the cowl onto the cowl mounting

ring too hard as this could deform the shape of the cowl.

❏

18. Reaching carefully into the inside of the cowl, tack

glue the cowl to the cowl mounting ring with medium CA. Be

sure you do not move the cowl while reaching inside. Spray

the glue with accelerator to make sure the glue is fully cured.

❏

19. Once the glue is fully cured, remove the cowl and the

cowl mounting ring from the fuselage by removing the four

socket head cap screws that hold the cowl to the fuselage.

Apply a small bead of medium CA to firmly attach the cowl

mounting ring to the cowl. Allow the CA to fully cure.

❏

20. Mix 1/4 ounce of 6-minute epoxy with microballoon

filler. Apply a fillet of the epoxy to the cowl mounting ring and

the cowl. The fillet should be made on the front of the cowl

mounting ring. Applying the epoxy to the back of the ring

could interfere with the cowl mounting tabs.

❏

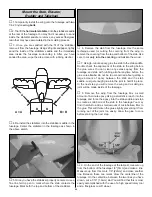

21. Now is a good time to make any cut-outs in the cowl

for things such as a needle valve extension, choke extension

or a remote glow adapter. If you are using a long-necked

Nicd glow driver there is no need for a remote glow plug

adapter. For our installation we chose to use a Sullivan Head

Lock Remote (MODP1221). Re-install the cowl onto the

fuselage. This will allow you to look into the front of the cowl

to determine exactly where any holes may have to be drilled.

When you have finished, remove the cowl.

❏

22. With the fuselage standing on its tail, place the dummy

engine over the engine. Then place the cowl over the dummy

engine. Attach the cowl to the fuselage with the four socket

head cap screws. To position the dummy engine you will

need two 9" [229mm] balsa sticks and two small rubber

bands (not included). Loop a rubber band through a couple

of the aluminum tubes on one side of engine crankshaft.

Insert the stick through the rubber bands and place the stick

onto the front of the cowl. This will pull the dummy engine into

the front of the cowl. Repeat this with the second stick and

rubber band on the other side of the engine crankshaft.

❏

23. Position the dummy engine so that the cut out is over the

engine cylinder and the hole you cut in the center of the dummy

engine is centered on the engine thrust washer. Be sure the

center cylinder on the dummy engine is centered at the top of

the fuselage and the oil sump is centered on the bottom of the

fuselage. When you are satisfied with the positioning of the

dummy engine, carefully remove the cowl from the fuselage

being careful not to disturb the dummy engine.

❏

24. Tack-glue the dummy engine to the cowl from inside

the cowl. Re-install the cowl to the fuselage to verify that the

dummy engine is placed properly. When you are satisfied

with the way it fits, remove the cowl from the fuselage and

permanently glue the dummy engine to the cowl from inside

the cowl with 6-minute epoxy mixed with microballoon filler.

21