❏

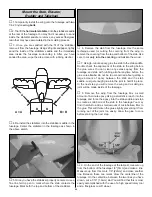

6. On the left side of the fuselage below the stab are

located two molded pushrod exit locations. Cut them out. On

the right side of the fuselage is located one molded pushrod

exit. Cut it out as well.

❏ ❏

7. Locate three .074 x 17-1/2" [444mm] wires threaded

on one end. From one wire cut a 6-1/2" [165mm] rod with the

threads at one end.

❏ ❏

8. Locate three 1/4" x 16" [6mm x 406mm] wood dowels.

On one dowel measure from one end 1" [25mm] and make a

mark. On the mark, drill a 5/64" [2mm] hole through the dowel.

❏ ❏

9. From the end of the dowel to the hole make a

groove the same width as the pushrod wire.

❏ ❏

10. On the non-threaded end of the 6-1/2" [165mm] wire

make a 90 degree bend 1/4" [6mm] from the end of the wire.

❏ ❏

11. Insert the wire into the hole in the dowel. Glue the

wire to the groove with a small amount of medium CA.

❏ ❏

12. Locate one of the 2-3/8" [60mm] long pieces of

heat shrink tubing. Cut it in half. Slide one piece over the

wire and the dowel. Then shrink the tubing tightly to the

dowel and wire. The tubing can be shrunk with either a

modeling heat gun or a match.

❏ ❏

13. From the leftover .074 x 17-1/2" [444mm] wire cut

a 7-1/2" [190mm] long, non-threaded wire. Make a 90 degree

bend 1/4" [6mm] from the end of the wire.

❏ ❏

14. On the opposite end of the dowel measure in 1"

[25mm] and make a mark. On the mark, drill a 5/64" [2mm]

hole through the dowel.

❏ ❏

15. From the end of the dowel to the hole make a groove.

❏ ❏

16. Insert the wire into the hole in the dowel. Glue the

wire to the groove with a small amount of medium CA.

❏ ❏

17. Slide the remaining half of the heat shrink tubing

over the wire and dowel. Shrink the tubing tightly to the

dowel and wire.

25

25